ZZSS China Full Automatic Machine for Bar Soap Making: Efficiency for Laundry, Toilet & Hotel Soaps

The demand for high-quality bar soap – be it for laundry, toilet, or hotel applications – continues to grow globally. Meeting this demand efficiently requires modern, reliable production solutions. ZZSS China stands at the forefront, offering advanced Full Automatic Machines for Bar Soap Making designed to handle diverse formulations, including those utilizing raw materials like Palm Oil and pre-processed Soap Noodles.

ZZSS China’s integrated Automatic Soap Production Line represents a significant leap in manufacturing efficiency. This comprehensive system is engineered to transform raw materials into finished, stamped bars with minimal manual intervention, making it ideal for both large-scale operations and businesses aiming to scale up production.

Core Components Driving Efficiency:

Raw Material Handling & Mixing: The process begins with precise metering and blending of ingredients. A robust soap mixer or Mixing machine ensures consistent homogenization of fats like Palm Oil, caustic soda, additives, and pre-made soap noodles, creating a uniform base mass.

Refining & Homogenizing: Critical for premium bar quality, the soap plodder machine, particularly a Vacuum plodder, plays a vital role. This stage removes air pockets, refines the texture, and compresses the soap into a dense, continuous extrudate. Options like the OEM three roller grinding mill can also be integrated for specific refining needs.

Forming & Cutting: The extruded soap log then moves to cutting. An automatic block cutter machine or Electric washing soap cutter slices the log into precise, uniform blocks with high speed and accuracy, eliminating inconsistencies common with Manual Cutting Machines. Options include Pneumatic Cutting Machines or Electronic Cutting Machines for specific requirements.

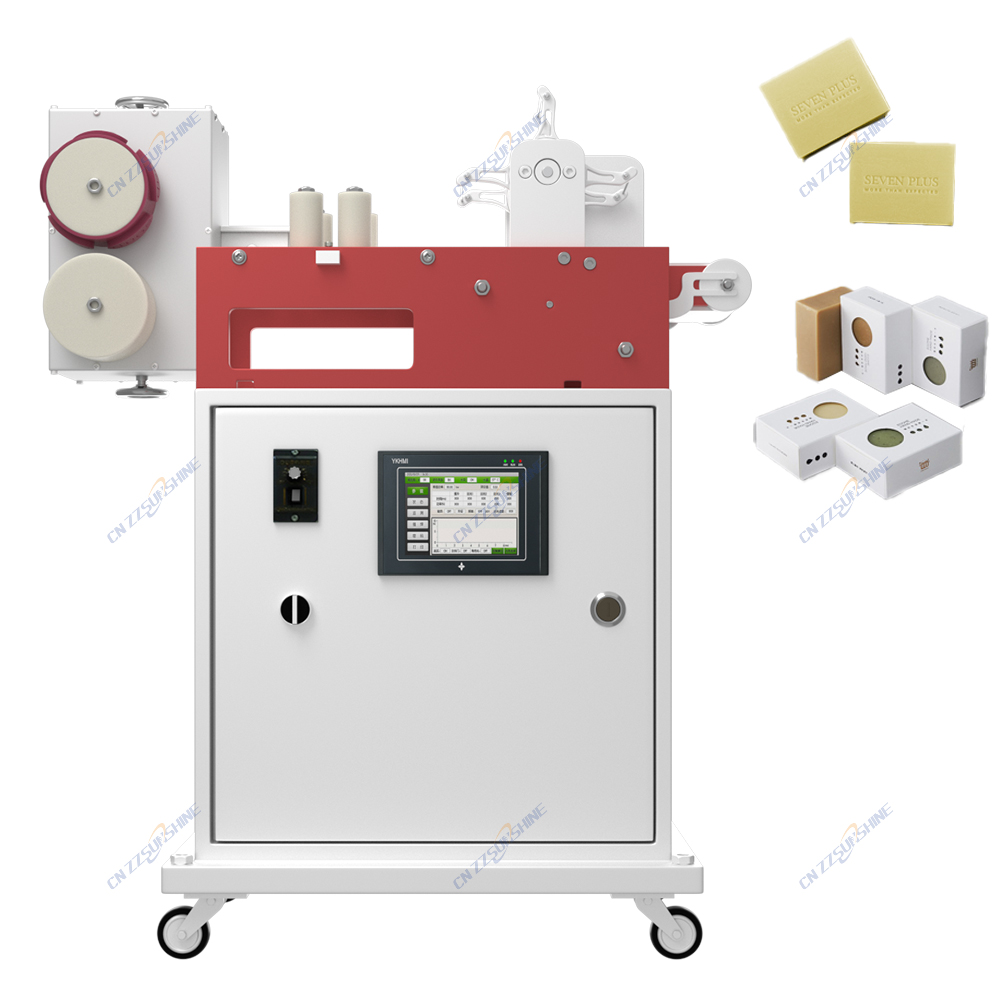

Finishing & Packaging: The cut bars proceed through shaping (often in an amalgamator) before final stamping. An Automatic Printer or Soap Stamping Machine imprints logos or designs reliably. Finally, a Film Packaging Machine wraps the finished bars securely for distribution. This streamlined sequence forms a complete toilet soap finishing line, laundry bar soap production line, or beauty soap making line.

Key Advantages of ZZSS Automation:

Significant Output: Designed for high-volume production of laundry soap, toilet soap, and hotel soap.

Consistent Quality: Automated processes ensure uniformity in size, weight, texture, and appearance batch after batch.

Reduced Labor & Costs: High automation dramatically reduces labor costs and minimizes human error.

Flexibility: Systems can be tailored (custom soap cutting machine, specific soap plodder configurations) to handle different soap types (laundry, beauty, toilet) and recipes.

Scalability: From Mini Soap Production Line setups to fully integrated Automatic soap production lines, ZZSS offers solutions for various capacities.

For manufacturers seeking to optimize their bar soap production – whether utilizing Palm Oil, soap noodles, or other formulations – investing in a ZZSS China Full Automatic Machine for Bar Soap Making provides a reliable pathway to increased efficiency, superior product quality, and enhanced market competitiveness. Explore the potential of a fully integrated soap making production line today.