For manufacturers serious about producing premium laundry, bath, or toilet soap bars, the vacuum plodder isn’t just another machine; it’s the critical component defining end-product quality. This specialized piece of equipment within a complete soap making production line transforms mixed soap base into the dense, consistent, and bubble-free bars consumers demand.

Understanding the vacuum plodder’s role is key. After the initial soap mixing stage, where oils, lye, and additives are combined in an industrial mixer for chemical processing, the resulting soap noodles or flakes enter the plodder. Here, a powerful screw mechanism forces the soap mass through a tapered barrel under immense pressure. Simultaneously, a continuous vacuum chamber rigorously extracts trapped air and residual moisture. This dual action of compression and de-aeration is what sets vacuum plodders apart from simple extrusion units.

The impact of this process on bar soap extrusion quality is profound. Eliminating air pockets prevents common defects like cracking, crumbling, or the formation of unsightly “lather killers” when the bar is used. Achieving optimal density ensures the bar lasts longer during use, a crucial selling point. Furthermore, the intense working refines the soap structure, contributing to a smoother feel and more polished appearance, essential for toilet soap finishing lines and beauty soap making lines.

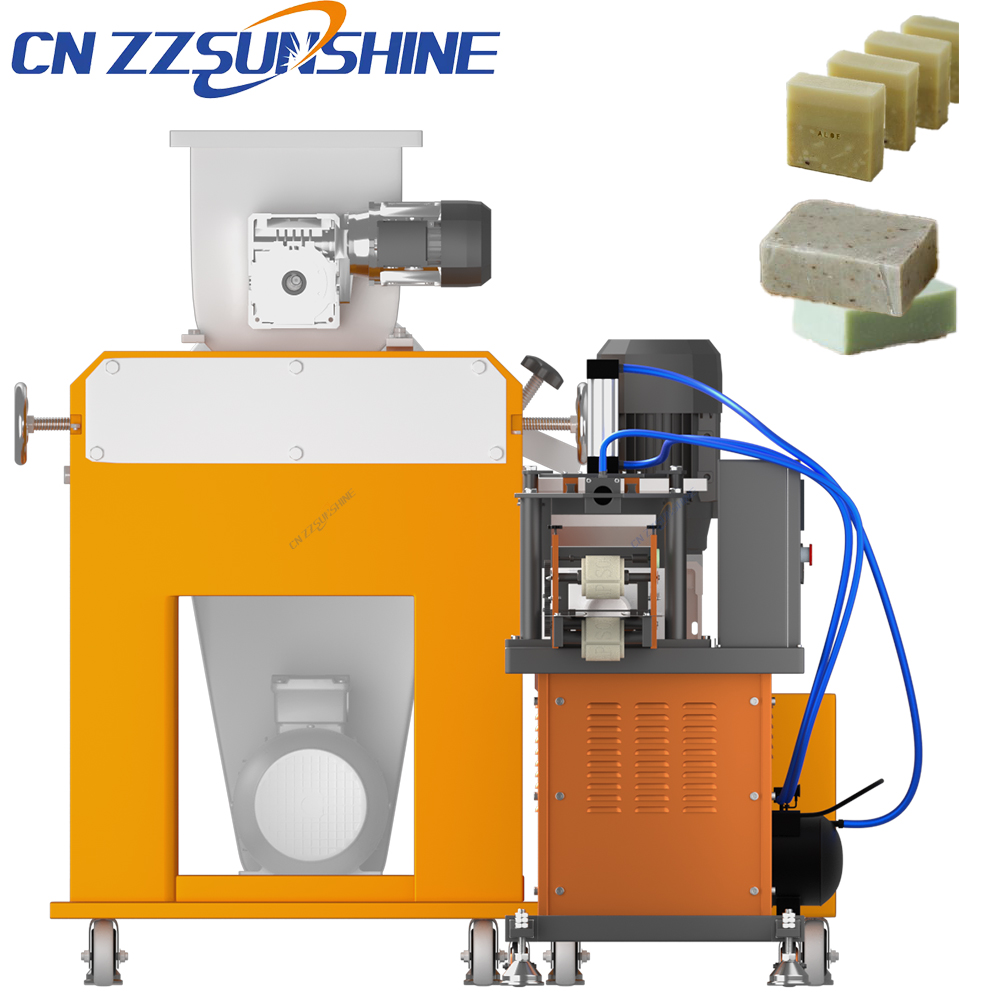

Choosing the right soap plodder machine for bar soap depends on several factors. Capacity must align with the overall laundry bar soap production line or bath soap making machine output. The design of the extrusion cone and final die plate dictates the bar’s shape and surface finish. Crucially, the vacuum system’s efficiency directly correlates with the final bar’s density and freedom from imperfections. Modern vacuum plodders are often integrated into fully automatic soap production lines, seamlessly linking with upstream soap mixers and downstream equipment like high-precision custom soap cutting machines or electric washing soap cutters.

Investing in a robust vacuum plodder translates directly to superior product quality, reduced waste, and enhanced brand reputation. It ensures the homogeneous soap paste exiting the mixer is transformed into dense, visually appealing, and high-performing bars ready for stamping, wrapping, and packing, whether for heavy-duty laundry soap or luxurious bath products.