Ever wonder how bar soap gets its consistent texture and density? The answer lies in specialized equipment, with the vacuum plodder being the critical workhorse. This machine isn’t just another step; it’s where quality is solidified in industrial soap making. Found in both laundry bar soap production lines and sophisticated toilet soap finishing lines, the vacuum plodder transforms milled soap noodles into a continuous, uniform bar.

How does it work? Soap noodles enter the plodder’s feed section. Inside, a powerful screw conveyor forces the material through a constricted barrel under high pressure. This crucial action compacts the noodles, eliminating air pockets – a process known as de-aeration. The vacuum chamber actively removes any remaining air and moisture vapor, preventing bubbles and ensuring structural integrity. This results in a homogeneous, dense soap mass. Finally, the soap is extruded through a die plate, forming a continuous, solid log with the desired cross-section, ready for precise cutting.

Why is a vacuum plodder essential? First, it guarantees product consistency. Homogeneous soap texture means every bar has the same feel, weight, and performance. Second, de-aeration prevents unsightly bubbles and voids, improving the bar’s appearance and durability – it won’t crumble or develop holes. Third, the compaction process enhances the bar’s hardness and longevity in use. For manufacturers, this translates to fewer rejects, higher quality output, and satisfied customers, whether producing simple laundry soap or premium beauty bars.

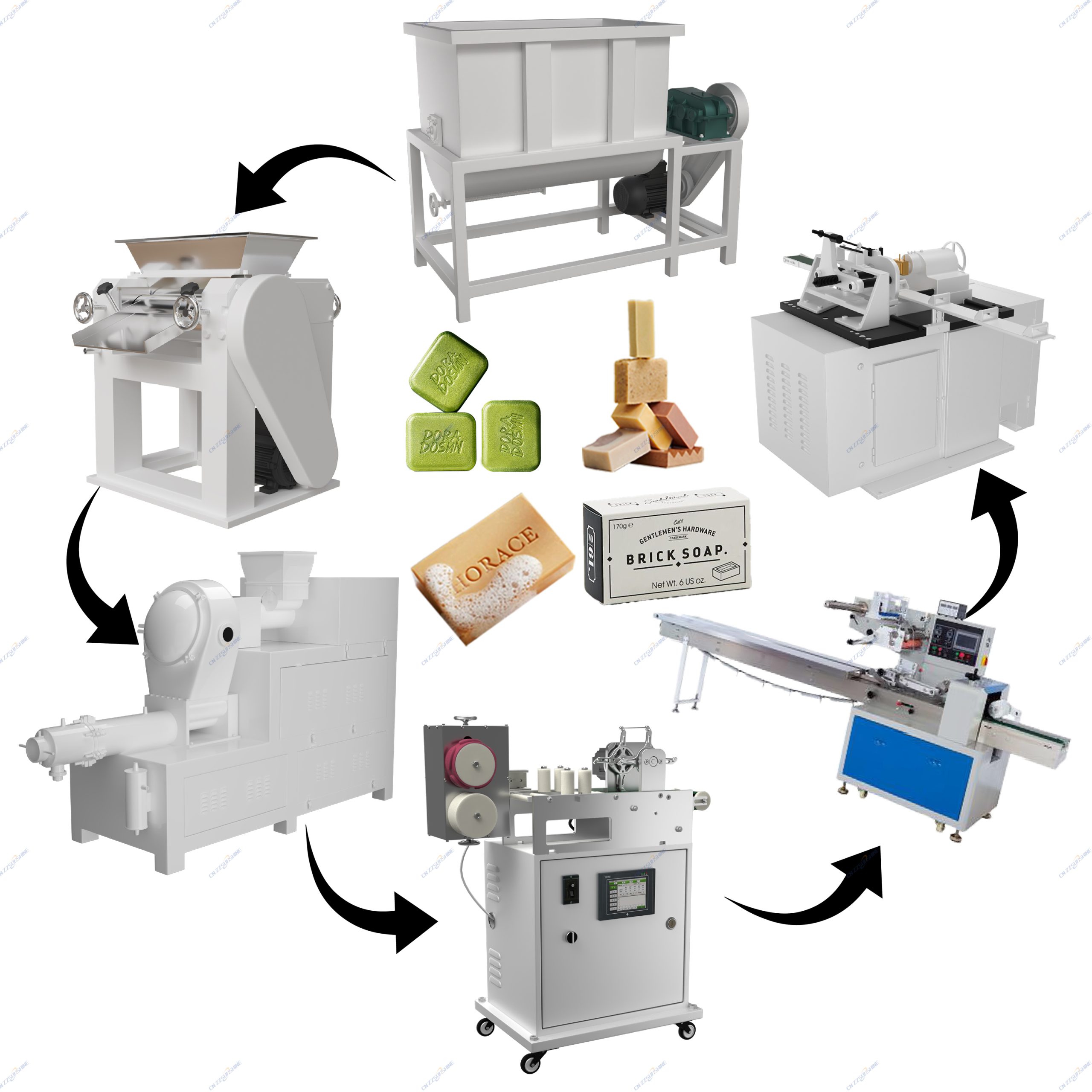

Integrating a high-performance vacuum plodder is fundamental for any efficient automatic soap production line. It works seamlessly alongside other key units like high-shear soap mixers for thorough blending and specialized custom soap cutting machines for precise sizing. This combination ensures a smooth, high-output operation. For businesses aiming for top-tier bar soap production, investing in a reliable vacuum plodder isn’t optional; it’s the cornerstone of achieving professional results and maintaining a competitive edge in the market. The quality extruded directly impacts the final product’s success.