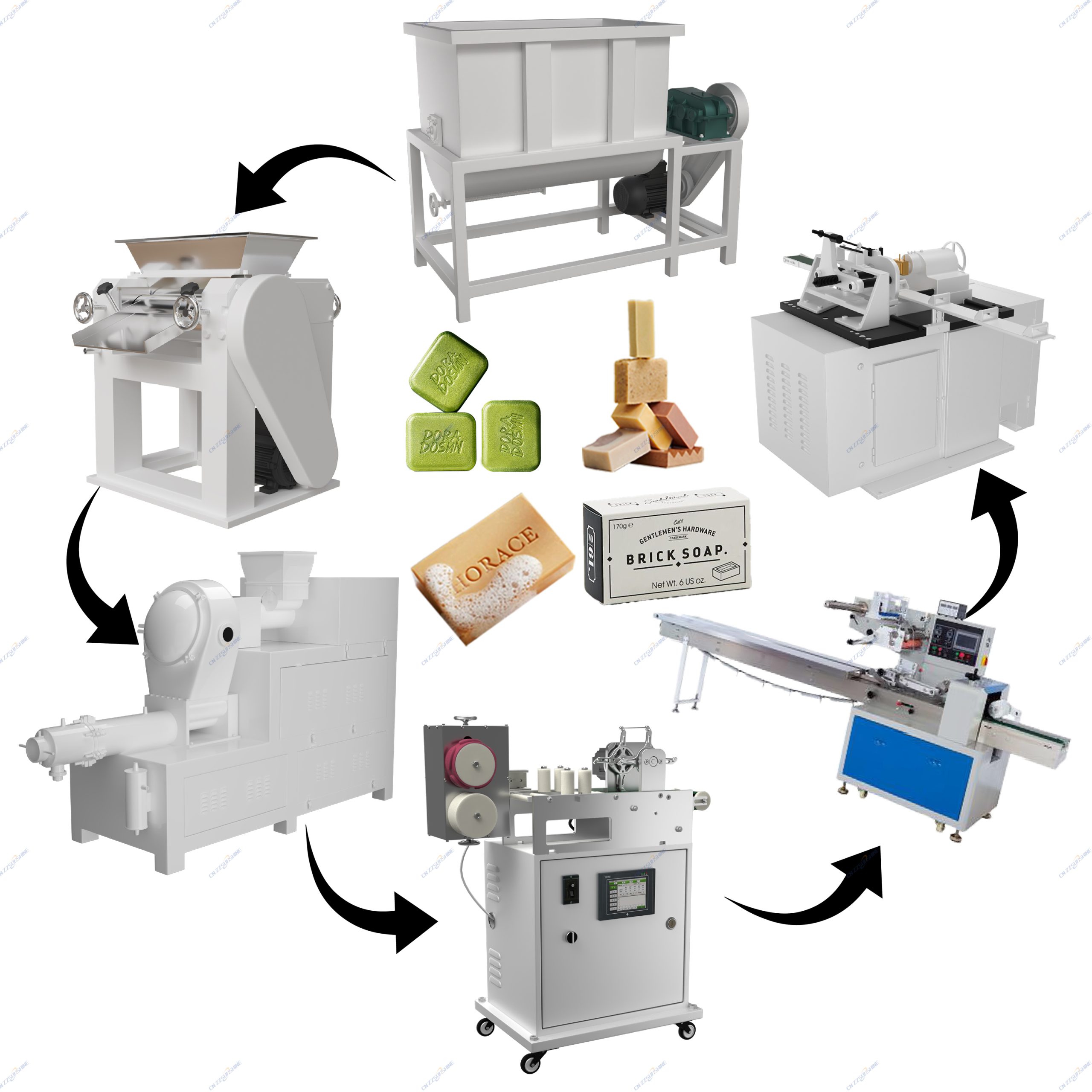

In the competitive world of soap manufacturing, achieving consistent quality, high output, and cost-effectiveness is paramount. This is where investing in a complete **automatic soap production line** becomes a strategic advantage, transforming raw materials into finished bars with remarkable precision and minimal manual intervention. Moving beyond standalone units like a **soap mixer** or **soap plodder**, an integrated line seamlessly connects every critical stage.

The process typically begins with precise ingredient blending in a robust **mixing machine**, ensuring uniform distribution of oils, fats, lye, and additives. This homogenous mixture is then fed into the core refining unit, often a high-performance **vacuum plodder**. Under vacuum conditions, this machine meticulously removes air pockets, compacts the soap base, and extrudes a continuous, dense log of exceptional smoothness and consistency – essential for premium bar quality. This step is crucial whether producing **laundry bar soap** or luxury **beauty soap**.

The extruded log then progresses to the cutting stage. Here, sophisticated options like an **electric washing soap cutter** or a **custom soap cutting machine** come into play. These units deliver precise, clean cuts at high speed, creating perfectly dimensioned bars ready for stamping and finishing. The automation extends to downstream handling, significantly reducing labor costs and physical handling risks compared to manual **cutter** operations.

The benefits of implementing an **automatic soap production line** are compelling. **High efficiency flour mill plant** levels of throughput become achievable, catering to large-scale demands for both **laundry soap making lines** and sophisticated **toilet soap finishing lines**. Consistency is dramatically improved, batch after batch, minimizing waste and rework. Labor requirements are drastically reduced, freeing personnel for higher-value tasks and improving overall operational safety. Furthermore, the inherent scalability of such lines allows manufacturers to easily ramp up production volume as market demand grows.

For manufacturers aiming to dominate the market, whether specializing in **bath soap making machines** or industrial **laundry soap production**, the integration offered by a fully **automatic soap production line** is no longer a luxury, but a necessity. It represents the optimal path to superior product quality, maximized operational efficiency, and sustained profitability in today’s demanding marketplace.