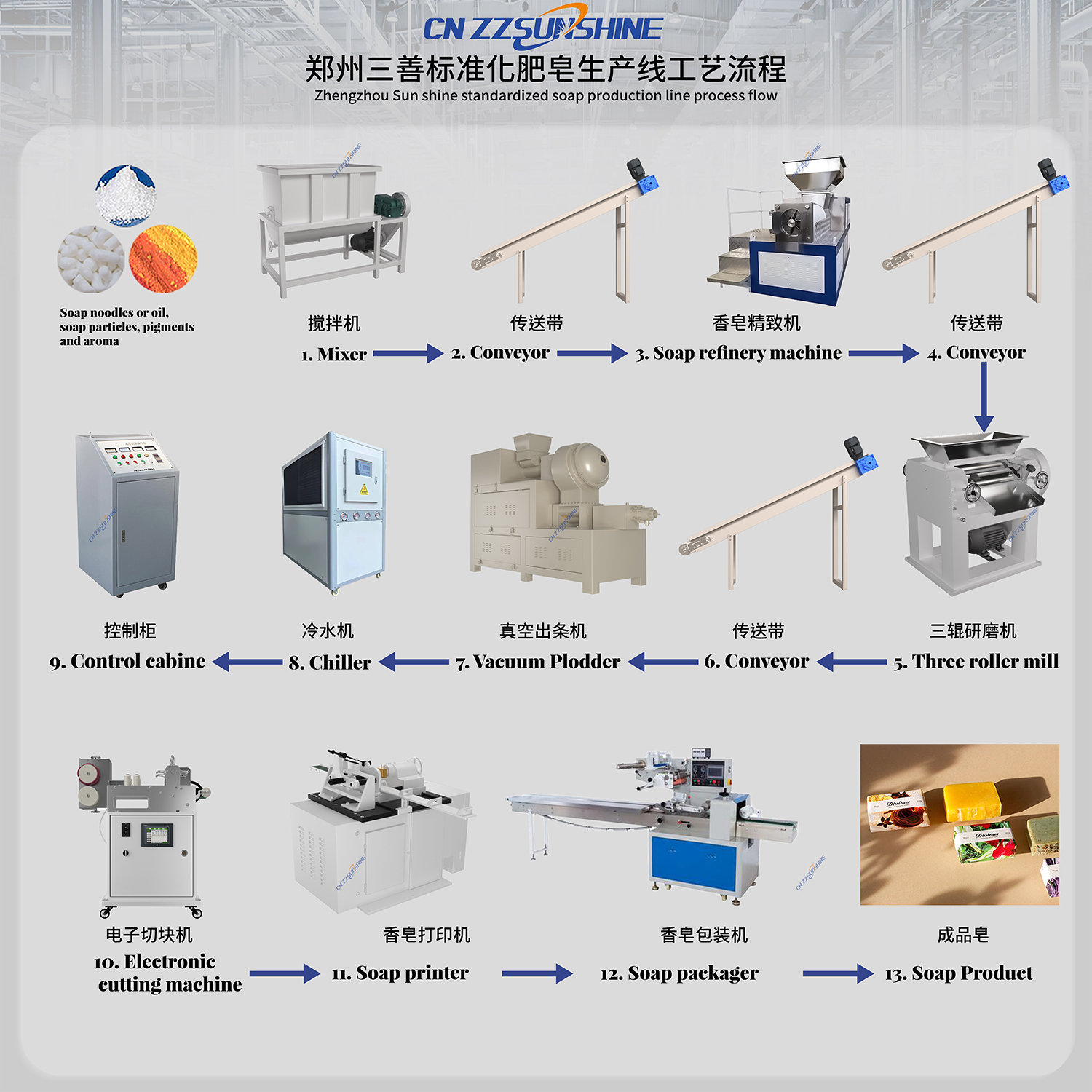

For manufacturers scaling bar soap production, transitioning from batch processing to a fully integrated automatic soap production line delivers transformative gains in output, consistency, and cost control. This seamless integration of specialized machinery handles every stage – from raw material blending to finished bar stamping – with minimal manual intervention. At the heart of the line lies the industrial mixer for chemical processing. This robust unit ensures homogeneous blending of fats, oils, alkali, additives, and recycled soap noodles under precisely controlled conditions, forming the foundational soap base. Critical for refining texture and removing air pockets, the vacuum plodder machine compresses and extrudes the soap mass through a die. This stage is vital for producing dense, long-lasting laundry bar soap or smoother toilet soap.

Following extrusion, the continuous soap log enters the cutting phase. High-speed automatic block cutter machines, often utilizing precise electric washing soap cutter mechanisms, slice the log into uniform blanks at impressive rates. For intricate shapes or embossing, custom soap cutting machines can be integrated. The final stage involves finishing equipment tailored to the soap type – whether it’s a laundry soap making line requiring simple cooling and stamping, or a sophisticated toilet soap finishing line incorporating polishing, milling (potentially using a three roller mill for cosmetics-grade additives), and wrapping.

Investing in a complete bath soap making machine system offers compelling advantages. Automation drastically reduces labor dependency and human error. Precise control over mixing parameters, plodding vacuum, extrusion pressure, and cutting dimensions ensures unparalleled batch-to-batch consistency crucial for brand reputation. Output scales dramatically, meeting high-volume demands for laundry bar soap production lines or beauty soap making lines. Furthermore, optimized material usage and reduced waste contribute significantly to the bottom line. Leading china feed processing machine suppliers often diversify into soap machinery, offering solutions from individual components like a heavy-duty soap plodder to turnkey soap making machine installations. When selecting an OEM three roller grinding mill or other line components, prioritize integration capability and robust after-sales support. The shift to automation isn’t just about speed; it’s about achieving reliable, high-quality soap production at scale.