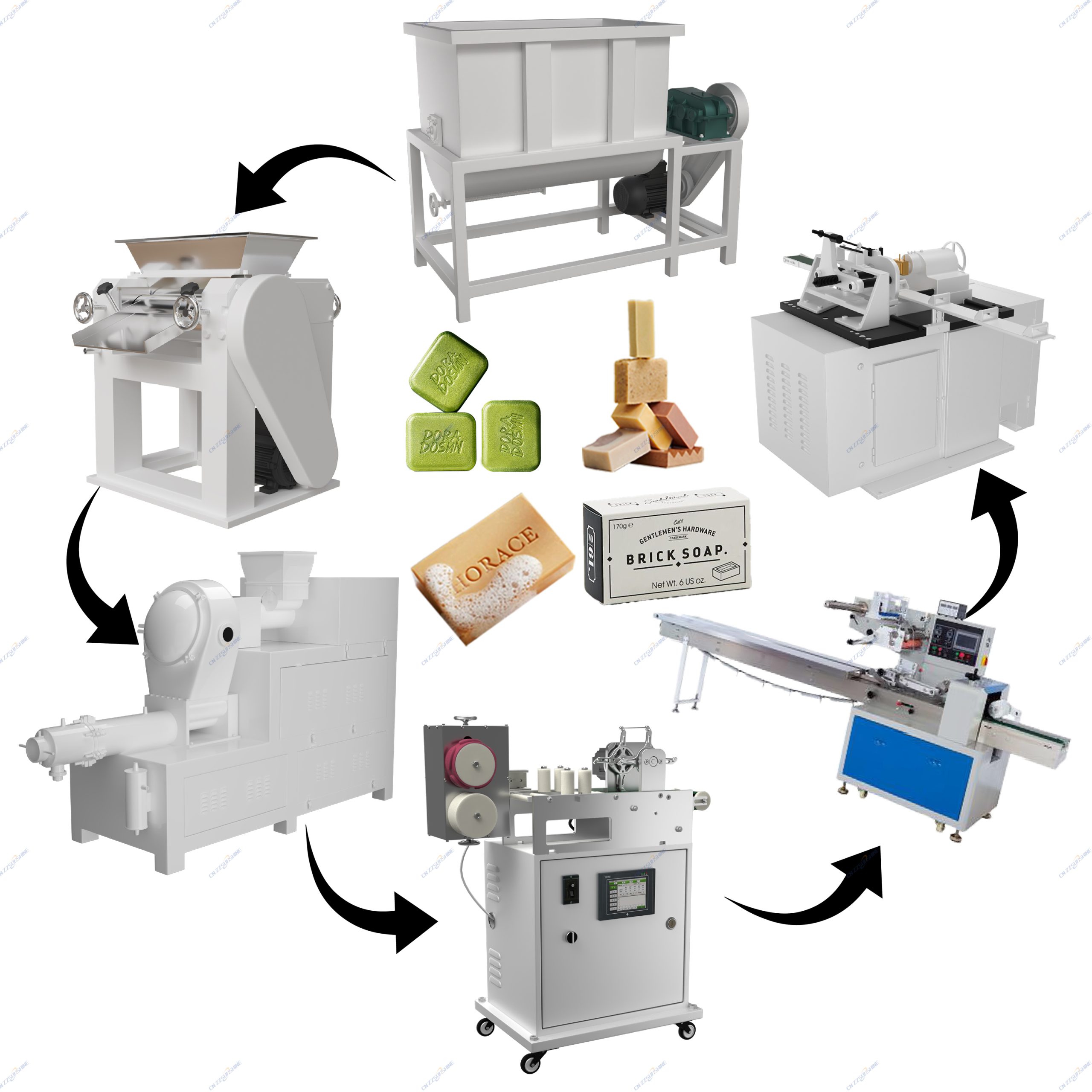

The modern soap manufacturing sector demands unparalleled efficiency, consistency, and scalability. This is where the **automatic soap production line** becomes indispensable, integrating specialized machinery to transform raw materials into finished bars, whether for laundry or personal care, with minimal manual intervention.

At the heart of any robust **laundry bar soap production line** or sophisticated **toilet soap finishing line** lies precision engineering. The process typically begins with a high-shear **soap mixer** or **mixing machine**, crucial for homogenizing fats, oils, lye, and additives. This ensures the chemical reaction proceeds uniformly, forming the soap base. For **beauty soap making line** applications demanding finer textures and specific properties, further refinement often occurs using an **OEM three roller grinding mill** or **three roller mill for cosmetics**. This step meticulously reduces particle size and enhances smoothness.

The refined soap mass then moves to the extrusion stage, a critical phase defining bar density and quality. Modern lines utilize advanced **vacuum plodder** technology. A **vacuum plodder for higher density** removes air pockets, resulting in harder, longer-lasting bars with superior lather and reduced waste – essential for both **laundry soap making line** output and premium **bath soap making machine** operations. The **soap plodder machine for bar soap** continuously compresses the paste, forming a solid, uniform log ready for shaping.

Downstream, automation continues with precision cutting. High-speed **electric washing soap cutter** units or **custom soap cutting machine** solutions slice the extruded logs into individual bars with exact dimensions and minimal residue. This step is vital for maintaining product uniformity and meeting specific customer requirements, particularly in **toilet soap finishing line** setups where aesthetics are paramount.

Finally, the line often incorporates automated stamping, cooling tunnels (potentially linked to a **factory price industrial chiller** for process cooling), and packaging systems. The integration of each component – from the initial **soap mixer** and **vacuum plodder** to the final **cutter** – within a seamless **automatic soap production line** delivers significant advantages: drastically reduced labor costs, enhanced product consistency, higher throughput, improved safety, and superior quality control. Investing in this integrated **soap making machine** technology is no longer a luxury but a fundamental requirement for competitive and sustainable industrial **soap making production line** operations.