The Heartbeat of Precision: Toilet Soap Moulds Die for Your Stamping Machine

In the intricate ballet of soap production, where efficiency meets artistry, the final impression left on each bar is paramount. This defining moment hinges on a critical, yet often understated component: the toilet soap moulds die used within your soap stamping machine. More than just a shape, these dies are the very essence of your brand identity, pressed onto every single bar that rolls off your laundry bar soap production line or toilet soap finishing line.

Whether operating a large-scale automatic soap production line or a more compact mini soap production line, the quality and precision of your soap mould dies directly impact product consistency, brand recognition, and overall operational efficiency. These dies, typically crafted from robust metals like metal copper brass soap mould, are the unsung heroes transforming a simple extruded log into a finished, market-ready product.

The Crucial Role of Soap Mould Dies in Stamping

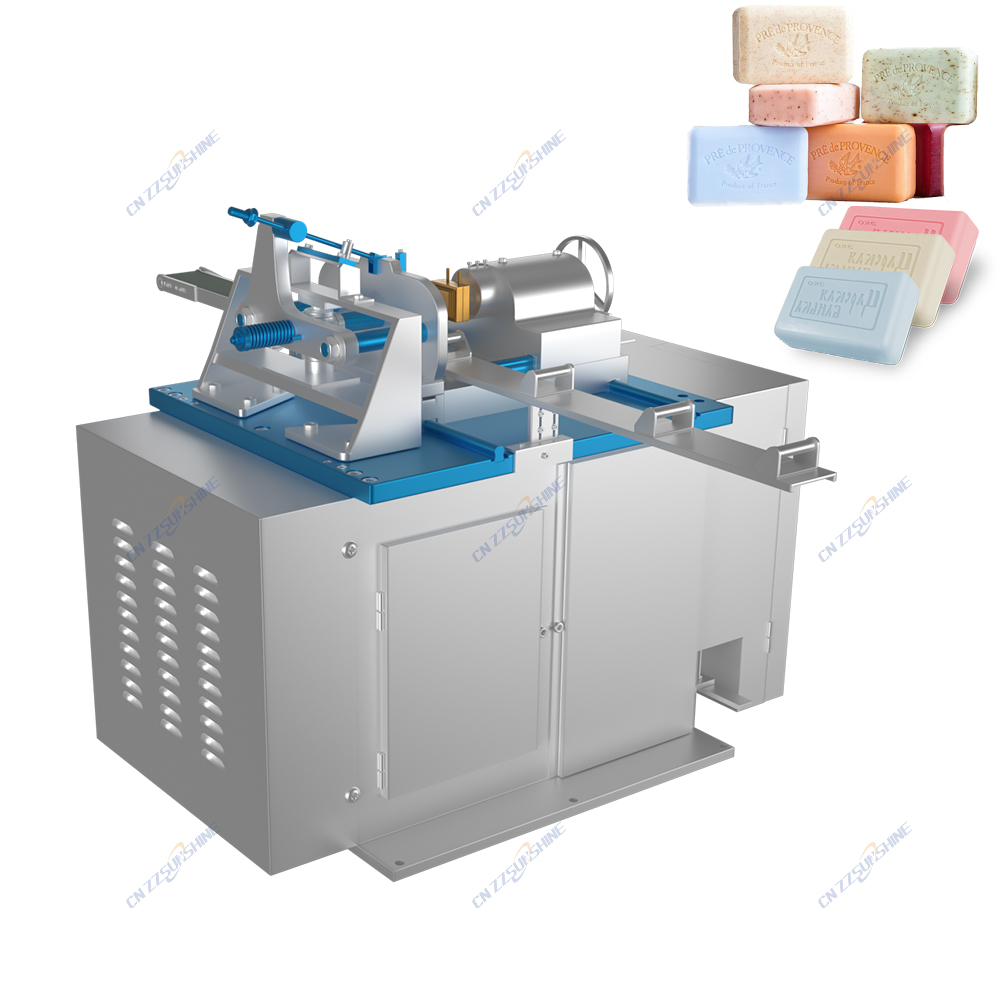

Imagine your soap stamping machine as a precision press. Its core function is to impart the desired logo, design, or text onto the soap bar surface with speed and consistency. The mould die is the element that physically makes this mark. It’s mounted onto the stamper head and comes into direct contact with the soap under significant pressure.

Precision Replication: A high-quality die ensures your design is replicated perfectly every single time, bar after bar. This consistency is vital for brand integrity, especially in competitive markets where visual appeal matters.

Durability Under Pressure: Soap stamping involves significant force. Dies made from superior materials like hardened brass or copper alloys withstand this pressure and resist deformation, ensuring longevity and reducing downtime for replacements. Cheap, soft metal dies wear down quickly, leading to blurred impressions and increased costs.

Clean Release: The material and finish of the die play a crucial role in how cleanly it releases from the soap surface after stamping. A well-polished, appropriately designed die minimizes sticking, preventing product damage and machine jams that can halt your automatic printer or semi-automatic printer.

Design Flexibility: For brands seeking unique identities, custom soap mould dies allow for intricate designs, specific fonts, and complex logos that set products apart on the shelf. This level of customization is achievable whether integrated into a high-speed automatic soap production line or used with smaller equipment.

Material Matters: Why Metal Copper Brass Soap Moulds Lead

While various metals can be used, metal copper brass soap mould dies are frequently preferred for several compelling reasons:

Machinability: Brass offers excellent machinability. This allows manufacturers to create highly detailed and intricate designs with sharp edges and fine lines, translating your brand elements faithfully onto the soap. Copper alloys also share this beneficial property.

Corrosion Resistance: Soap environments can be corrosive over time. Brass and copper alloys exhibit good resistance to corrosion, ensuring the die maintains its integrity and surface quality through repeated use and exposure to moisture and soap residues.

Strength and Durability: These materials provide the necessary hardness to withstand the repeated impact forces of the stamping process without excessive wear or cracking, unlike softer alternatives.

Polished Finish: Brass and copper can be polished to a very smooth finish, facilitating a cleaner release from the stamped soap bar and reducing the likelihood of the soap sticking to the die face.

Integration Within the Broader Soap Making Production Line

The soap stamping machine, equipped with its vital toilet soap moulds die, is typically a key station within a comprehensive soap making production line. It often follows extruders like the soap plodder (especially a vacuum plodder for higher quality bars) and cutting equipment – which could range from an automatic block cutter machine to a manual cutting machine, electronic cutting machine, or pneumatic cutting machine, depending on the line’s automation level.

Preceding these stages, the soap mass is prepared using equipment such as a soap mixer or mixing machine, and refined using components like an OEM three roller grinding mill. For liquid products, lines might incorporate washing liquid production equipment, while solid bars proceed through extruding, cutting, stamping, and potentially drying and film packaging machine stations.

Investing in Quality: Ensuring Peak Performance

Selecting the right toilet soap moulds die is an investment in your product’s quality and your production line’s efficiency. Partnering with manufacturers who understand the demands of the soap making machine industry is crucial. Look for providers offering:

Precision Engineering: Dies must be manufactured to exacting tolerances.

Material Expertise: Knowledge of the best alloys (like metal copper brass soap mould) for specific soap types and production volumes.

Custom Design Capabilities: Ability to translate your unique designs into functional dies.

Durability Guarantees: Dies that promise longevity even under high-volume stamping.

Conclusion

The humble toilet soap moulds die, crafted from durable materials like metal copper brass soap mould, is far more than a simple shaping tool. It is the final arbiter of your brand’s visual identity on every bar of soap. Its precision, durability, and quality directly influence the efficiency of your soap stamping machine and the overall output of your soap making production line, be it a full laundry soap making line, bath soap making machine setup, or a specialized beauty soap making line. Investing in superior dies ensures consistent, high-quality impressions, minimizes downtime, and ultimately protects your brand’s reputation in the marketplace. Choose wisely, and let every stamp tell your story perfectly.