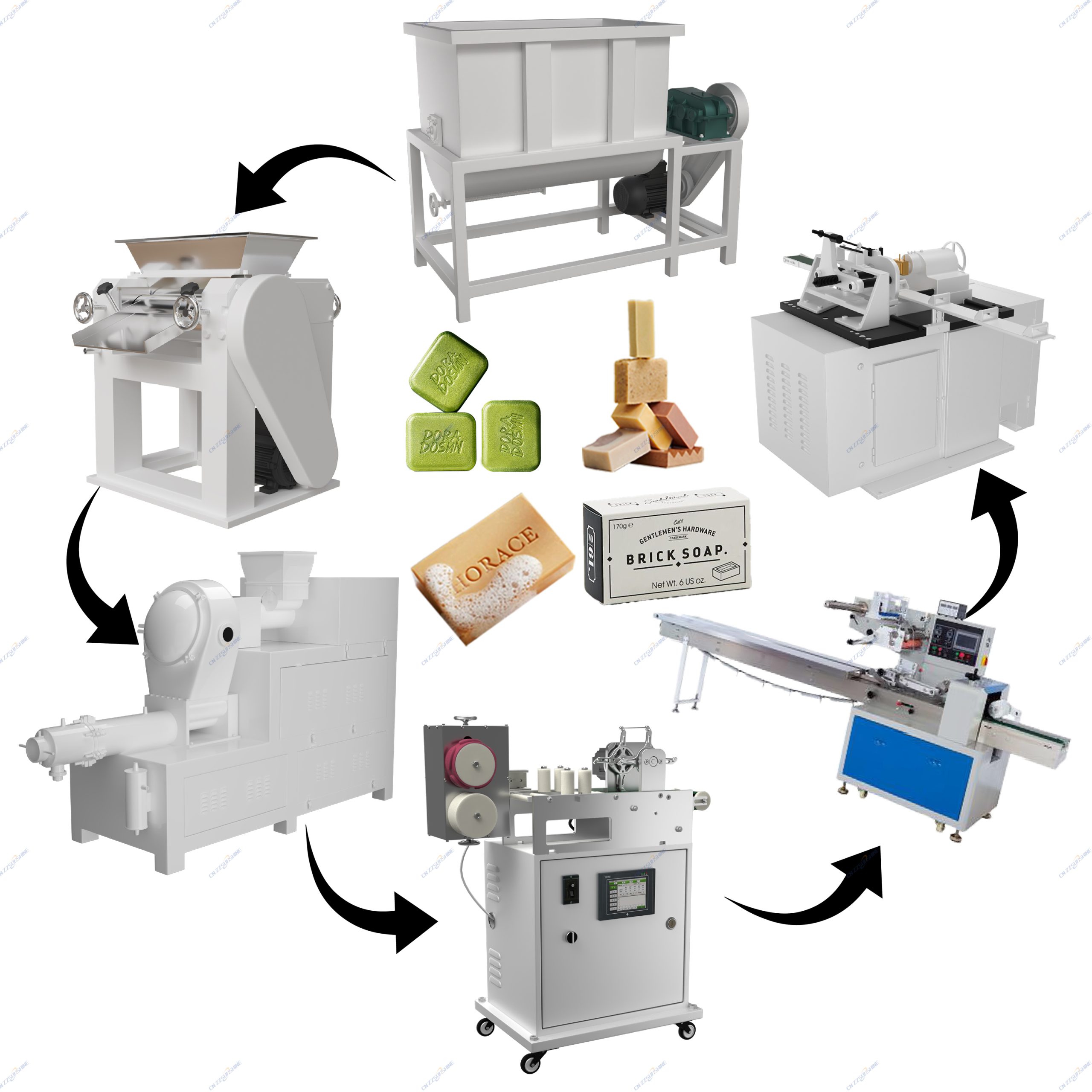

In today’s competitive personal care market, achieving consistent quality and high-volume output demands advanced manufacturing solutions. Implementing an integrated **automatic soap production line** is no longer a luxury but a necessity for serious manufacturers targeting both **laundry bar soap production** and premium **toilet soap finishing lines**. This comprehensive system seamlessly connects critical stages, replacing labor-intensive manual processes with precision automation.

The journey begins with the **soap mixer**, where raw materials like fats, oils, and lye are blended into a homogenous mass. Modern **mixing machines** ensure thorough integration of additives and fragrances. This mixture then undergoes refinement, often utilizing a **three roller mill for cosmetics**-grade applications, creating a smooth, uniform texture essential for premium **bath soap making machines** or **beauty soap making lines**.

The refined soap base is fed into the core of the line: the **soap plodder machine for bar soap**. Specifically, a high-performance **vacuum plodder** is crucial. It compacts the soap, removes trapped air (preventing bubbles and ensuring density), and continuously extrudes a solid, consistent log of soap. This extrusion quality directly impacts the final bar’s integrity and feel.

Next, the continuous log moves to the cutting stage. A **custom soap cutting machine**, such as a precise **electric washing soap cutter**, slices the log into individual bars at high speed with minimal waste and uniform dimensions. This automation guarantees consistent bar weight and size, critical for packaging and consumer satisfaction. Following cutting, bars typically proceed through cooling tunnels and stamping stations on the **toilet soap finishing line**.

Finally, bars are efficiently packaged using an **automatic packing machine for food** or similar hygiene-grade equipment, ensuring product protection and presentation readiness. The entire **automatic soap production line**, from the initial **soap mixer** to the final packaged product, offers unparalleled **high efficiency**. While the initial investment requires careful consideration of **factory price industrial chiller** requirements for cooling and reliable **China feed processing machine supplier** partners for robust components, the ROI is compelling. Reduced labor costs, minimized waste, consistent product quality, and significantly increased throughput make adopting a complete **laundry soap making line** or **toilet soap finishing line** the strategic choice for scalable, profitable soap manufacturing.