Modern soap manufacturing demands precision, consistency, and cost-effectiveness. This is where the **automatic soap production line** becomes indispensable. Moving far beyond manual processes, these integrated systems streamline the entire journey from raw materials to finished bars, whether for **laundry bar soap production line**, **toilet soap finishing line**, or specialized **beauty soap making line**.

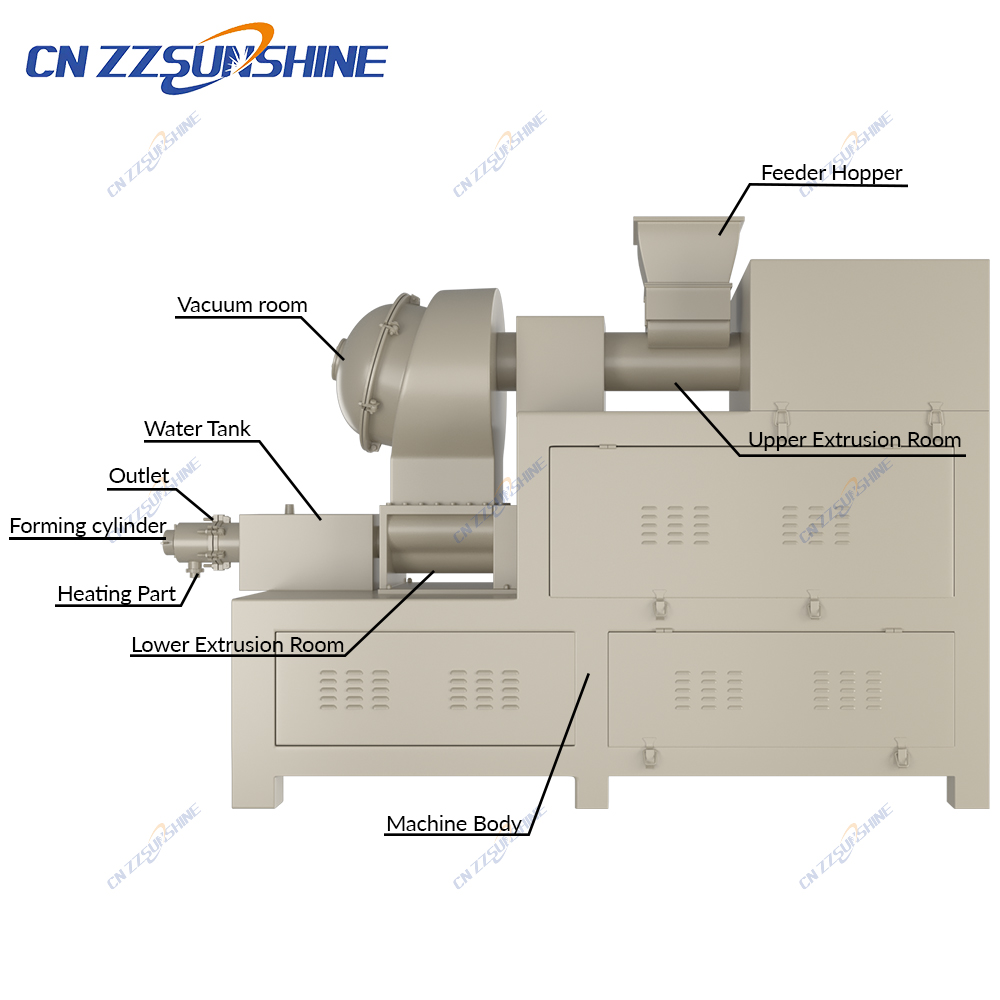

At the heart of any efficient operation lies robust mixing. An industrial mixer for chemical processing, specifically designed as a **soap mixer**, ensures homogeneous blending of fats, oils, lye, and additives under controlled conditions. This critical step directly impacts the final bar’s quality and performance. Following mixing, the compounded soap base undergoes refining and extrusion. This is where technology like the **three roller mill for cosmetics** (or general soap refining) and the essential **soap plodder machine** come into play. Particularly, advanced **vacuum plodder** technology removes air pockets during extrusion, crucial for producing dense, long-lasting bars with superior lather and a smooth finish – vital for both **laundry soap making line** and premium toilet soap outputs.

The extrusion process feeds the continuous soap log directly into the cutting phase. Here, **automatic soap cutting machine** solutions, ranging from high-speed **electric washing soap cutter** units to **custom soap cutting machine** designs for intricate shapes or sizes, deliver precise, consistent bars with minimal waste. Integration with downstream equipment like stampers, printers, and coolers completes the **toilet soap finishing line** or **bath soap making machine** setup.

Implementing a fully **automatic soap production line** offers undeniable advantages. It significantly boosts output while reducing labor costs and material waste. Consistent quality control is inherent throughout the **soap making machine** sequence, from the initial **soap mixer** stage to the final cutting and finishing. Furthermore, the inherent flexibility of modern lines allows manufacturers to switch between product types – like shifting from a **laundry soap making line** to a **beauty soap making line** – with minimal downtime, maximizing asset utilization. For businesses aiming to scale and compete, automating with a sophisticated **soap making production line** is no longer a luxury but a strategic necessity.