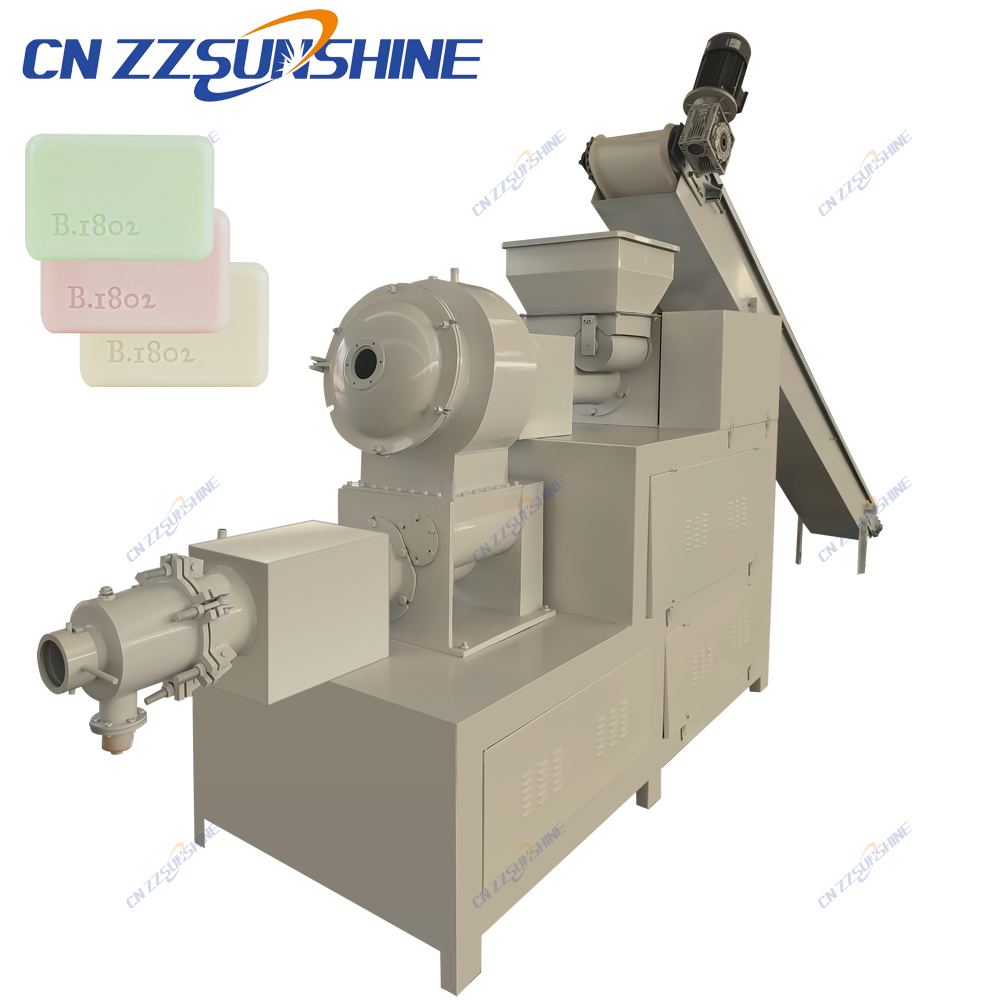

Moving beyond artisanal methods requires robust, integrated equipment. At the heart of any high-output **soap making machine** setup, especially for **laundry bar soap production line** or **toilet soap finishing line** operations, lies the **vacuum plodder**. This critical component defines bar quality and production efficiency.

A **vacuum plodder** performs two vital functions under significant extrusion pressure. First, it compacts the blended soap noodles, eliminating trapped air pockets that cause unsightly voids and bar crumbling. Second, the vacuum chamber actively draws out residual moisture and air, resulting in a denser, harder, more uniform bar with superior lathering properties and longer-lasting durability. This process is fundamental for both **laundry soap making line** and premium **beauty soap making line** outputs.

Integrating a high-performance **soap plodder machine for bar soap** into an **automatic soap production line** delivers tangible benefits. Consistent vacuum pressure and extrusion ensure every bar meets strict quality specifications, batch after batch. This level of uniformity is impossible to achieve manually. Moreover, the continuous extrusion process significantly boosts throughput compared to older, batch-dependent methods, maximizing return on investment for high-volume manufacturers.

Downstream efficiency is equally crucial. The extruded continuous soap log must be precisely cut. An **electric washing soap cutter** or a **custom soap cutting machine** provides clean, accurate cuts with minimal waste, maintaining the integrity of bars produced by the vacuum plodder. Paired with an efficient **soap mixer** earlier in the **soap making production line**, which ensures thorough homogenization of fats, lye, and additives, the vacuum plodder completes the core processing trio: mixing, refining (plodding), and cutting.

Choosing the right **soap plodder** involves considering factors like required output capacity (tons per hour), desired bar hardness, and compatibility with the overall **automatic soap production line** controls. Reputable manufacturers often offer **OEM three roller grinding mill** options for specialized milling needs within cosmetic or high-grade soap bases before the plodding stage. Investing in a well-designed **vacuum plodder** is not merely an equipment purchase; it’s a commitment to producing superior quality soap bars reliably and efficiently at scale, forming the indispensable core of any modern **soap making production line**.