The industrial production of high-quality bar soap, whether for laundry or toilet/bath applications, demands precision, efficiency, and consistent results. Achieving this hinges on a well-integrated **soap making production line**. Moving beyond rudimentary methods, contemporary lines combine specialized machinery to automate the process from raw materials to finished, wrapped bars, optimizing output and minimizing waste.

At the heart of any robust **laundry bar soap production line** or **toilet soap finishing line** lies the **soap mixer**. This **industrial mixer for chemical processing** ensures the homogeneous blending of fats, oils, alkalis, fragrances, and additives, forming the foundational soap base. Critical for achieving the desired texture and properties, the mixing stage sets the stage for subsequent refining.

The mixed soap base then undergoes refining and extrusion, typically involving a **soap plodder machine for bar soap**, often a **vacuum plodder**. This crucial component removes air pockets, compacts the soap mass, and extrudes continuous, dense logs of uniform consistency. The vacuum process is vital for producing blemish-free bars with the correct hardness and lathering characteristics. This stage is fundamental to both **bath soap making machine** operations and **laundry soap making line** setups.

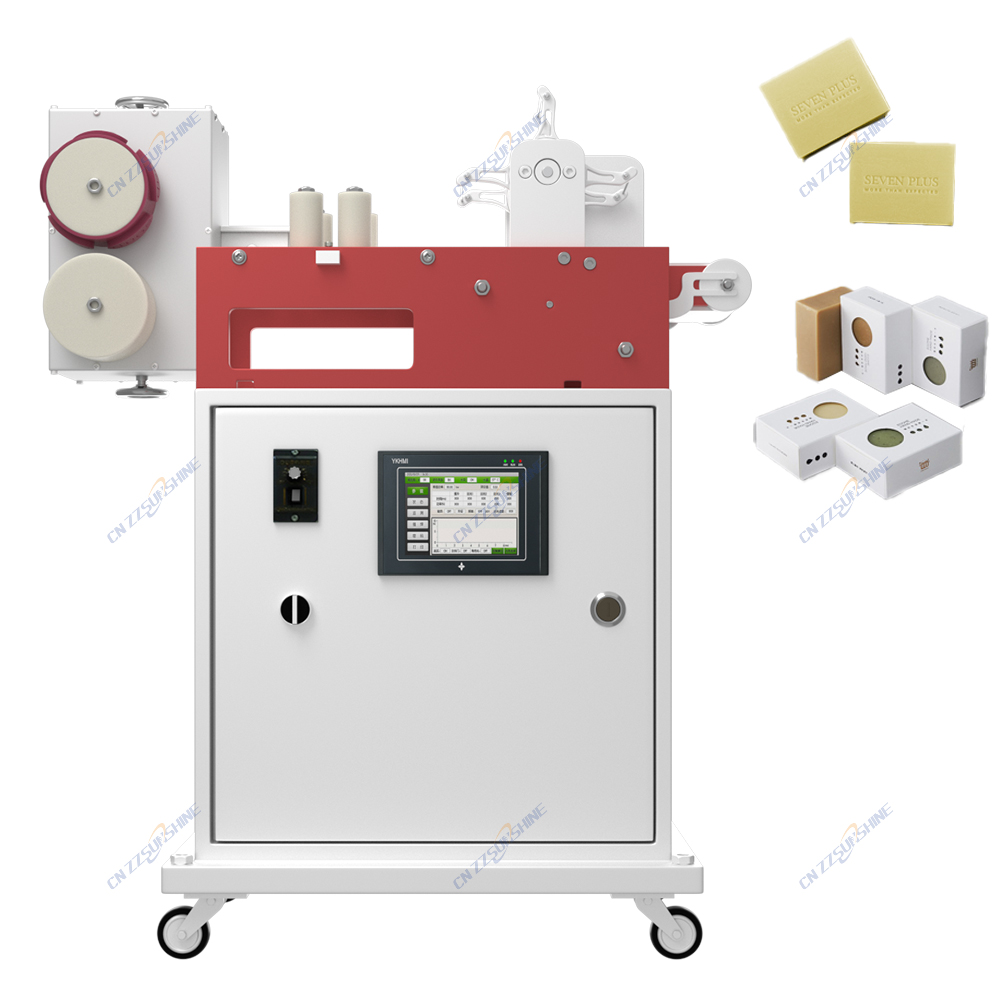

Following extrusion, the continuous soap log requires precise cutting. An **automatic soap production line** incorporates an **electric washing soap cutter** or a **custom soap cutting machine**. These **cutter** units slice the extruded logs into individual bars with exact dimensions and clean edges, often incorporating washing or air-knife systems to ensure smooth, ready-for-stamping surfaces. Precision here is non-negotiable for final product quality and branding.

For manufacturers seeking comprehensive solutions, partnering with a reliable supplier offering **OEM three roller grinding mill** options for specific refining needs, or complete **beauty soap making line** configurations, is key. Modern **soap making machine** technology emphasizes high throughput, energy efficiency, and adaptability to different soap formulations and bar sizes. Investing in an optimized **automatic soap production line** translates directly to enhanced productivity, consistent quality, and a stronger competitive position in the demanding personal and industrial cleaning markets. The integration of components like the **vacuum plodder**, precision **cutter**, and robust **mixing machine** creates a seamless flow essential for large-scale, profitable soap manufacturing.