Implementing a robust **laundry soap making line** is fundamental for manufacturers targeting consistent quality and high-volume output in today’s competitive market. Moving beyond fragmented manual processes, a fully integrated **automatic soap production line** seamlessly combines specialized machinery to handle every stage – from raw material preparation to finished bar packaging. This integration is key to achieving superior efficiency and product uniformity demanded by commercial buyers.

The heart of any effective **laundry bar soap production line** lies in precision mixing and refining. High-capacity **soap mixer** units, often double or triple shaft designs, ensure homogeneous blending of fats, oils, alkalis, and additives under controlled conditions. This initial uniformity is critical. The mixed paste then typically undergoes refining, frequently using robust **three roller mill for cosmetics and soap** applications. These **OEM three roller grinding mill** units are indispensable for achieving the desired smooth texture and particle size reduction, crucial for both laundry and **bath soap making machine** outputs.

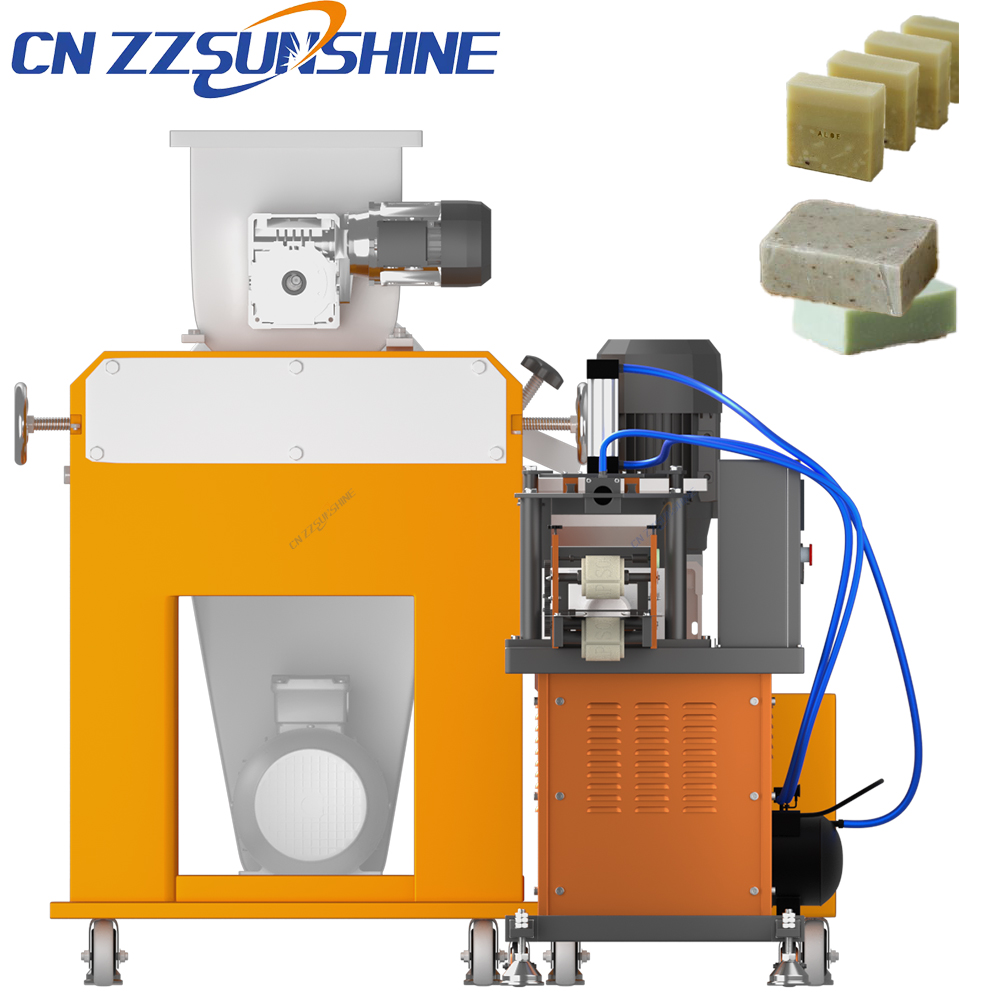

Following refining, the vacuum **soap plodder** stage becomes paramount. Modern **vacuum plodder** technology, integrated within the **soap making production line**, removes trapped air under vacuum, significantly enhancing bar density and longevity while preventing cracking. This dense extruded log is then precisely cut. Here, **custom soap cutting machine** solutions, including **electric washing soap cutter** units, provide flexibility for different bar sizes and shapes with minimal waste. For manufacturers also producing toilet soaps, the line can often incorporate modules from a **toilet soap finishing line** or **beauty soap making line** for additional stamping, polishing, or wrapping capabilities.

The advantages of investing in a cohesive **soap making machine** system are clear. Automation drastically reduces labor costs and human error. Consistent high throughput becomes achievable. Furthermore, partnering with experienced suppliers, potentially a **China feed processing machine supplier** with diversified expertise in chemical processing equipment, often provides access to reliable **industrial mixer for chemical processing** principles applied to soap and competitive machinery pricing. Ultimately, optimizing your **laundry soap making line** with the right **soap plodder machine for bar soap**, precise **cutter**, and integrated controls is the definitive path to scalable, profitable soap manufacturing.