Scaling soap production from artisanal batches to industrial volumes demands specialized, integrated machinery. A modern soap making production line transforms raw materials – oils, fats, alkalis, additives – into consistent, high-quality bars efficiently and reliably. Understanding the core components and their functions is key for manufacturers aiming to optimize their laundry bar soap production line or toilet soap finishing line.

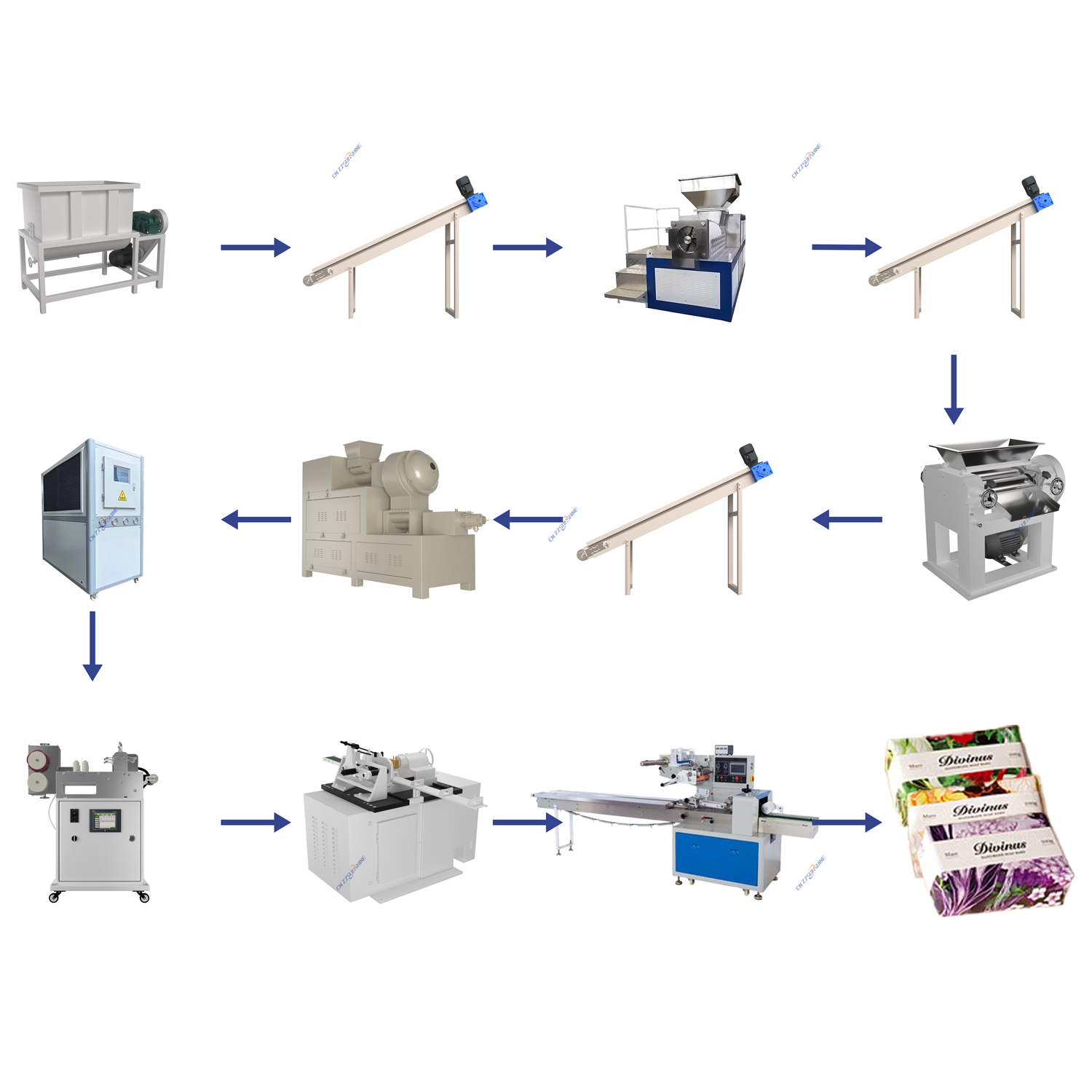

The process begins with precise mixing. An industrial mixer for chemical processing ensures fats, oils, and caustic soda are blended homogeneously under controlled conditions. This stage is critical for saponification and directly impacts final bar quality. The mixed soap base, often called ‘neat soap’, then moves to refining.

For denser, higher-quality bars, a vacuum plodder is indispensable. This sophisticated soap plodder machine removes air pockets, compacts the soap mass, and extrudes a continuous, uniform log under vacuum. The elimination of air prevents crumbling and ensures a smooth texture, vital for both bath soap making machine outputs and laundry soap applications. Some lines incorporate a three roller mill prior to plodding for ultra-fine milling of additives, especially in cosmetics or beauty soap making line setups where smoothness is paramount.

The continuous soap log then proceeds to cutting. An automatic soap cutting machine, often an electric washing soap cutter, slices the log into precise billets with minimal waste. For high-volume operations, an automatic soap production line will integrate sophisticated servo-controlled cutters ensuring consistent size and weight. Custom soap cutting machine configurations can handle diverse bar shapes and sizes, from simple rectangles to intricate embossed designs.

Downstream, finishing varies. A laundry soap making line might focus on rapid cooling and simple stamping, while a toilet soap finishing line incorporates polishing, stamping, and sophisticated wrapping via integrated automatic packing machine for food-grade hygiene. The choice between a dedicated laundry bar soap production line and a flexible system handling both laundry and toilet soaps depends on target markets and product diversity.

Investing in a well-designed soap making machine line, incorporating robust equipment like a high-efficiency vacuum plodder and precise automatic block cutter machine, translates to superior product consistency, reduced labor costs, and significantly higher throughput. Partnering with experienced OEMs ensures the integration of components like industrial chillers for machinery cooling and reliable automation controls, creating a truly high-efficiency flour mill plant equivalent for the soap industry – a turnkey solution driving profitability.