The demand for high-quality, durable bar soap – encompassing both laundry bar soap production lines and toilet soap finishing lines – continues to grow globally. Meeting this demand efficiently and consistently requires sophisticated automation. At the heart of any successful automatic soap production line lies the vacuum plodder machine, a critical component dictating the final product’s texture, density, and overall quality.

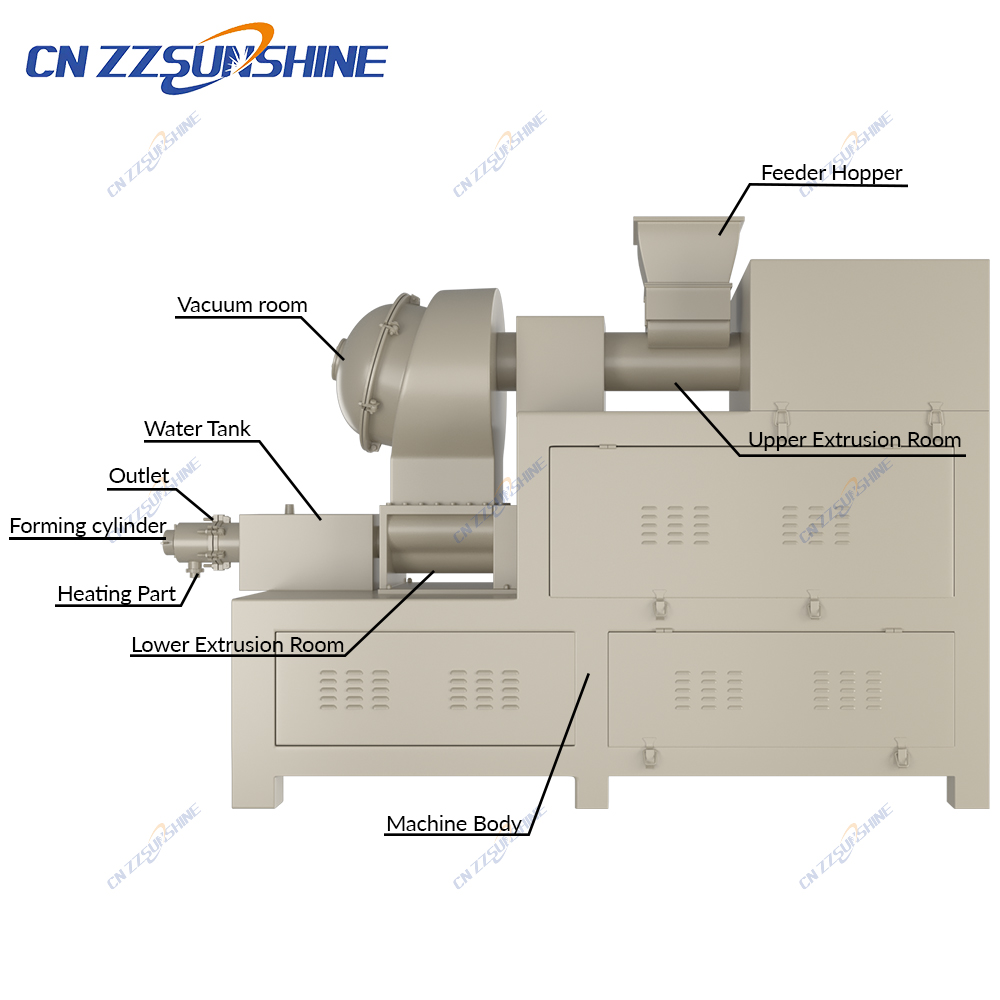

Unlike simpler soap mixer units used for initial blending, the vacuum plodder performs a vital refining and extrusion process. It receives homogenized soap noodles from the mixing machine stage. Within the plodder’s barrel, twin screws work the soap mass under carefully controlled temperature and, crucially, a strong vacuum. This vacuum extraction is paramount. It removes trapped air bubbles that would otherwise create voids, crumbling, and rapid dissolution in the final bar. The result is a dense, smooth, and uniform soap extrudate.

The quality of extrusion from the vacuum plodder directly impacts downstream operations. A consistent, well-compacted log of soap is essential for precision cutting in the next stage. Whether using a traditional soap cutting machine or a high-speed electric washing soap cutter, a uniform log ensures clean cuts, minimizes waste, and produces bars with sharp, professional edges. This consistency is vital for both bath soap making machine outputs and laundry bar production.

Integrating a high-performance vacuum plodder into your soap making production line offers significant advantages beyond just product quality. Automation reduces labor costs significantly compared to manual plodding methods. The continuous extrusion process enhances throughput, making the entire laundry soap making line or toilet soap finishing line far more efficient. Furthermore, the precise control over temperature and vacuum within the plodder allows manufacturers to adjust the hardness and translucency of the soap to meet specific market requirements, be it for a beauty soap making line or industrial laundry bars.

Choosing the right vacuum plodder, often paired with a robust soap mixer and an efficient cutter system, is fundamental for building a competitive and reliable automatic soap production line. It’s the key technology transforming blended soap mass into the premium, long-lasting bars consumers expect from both bath and laundry segments. Investing in this core technology ensures consistent quality, operational efficiency, and the ability to scale production effectively.