Optimize Your Laundry Soap Production: Efficiency and Quality from Start to Finish

Achieving consistent, high-quality laundry bar soap requires more than just ingredients; it demands reliable, efficient soap making machinery. Our complete washing soap production line is engineered for precisely this purpose. Featuring a stable structure and designed for easy operation, it streamlines the entire manufacturing process, from raw materials to finished bars.

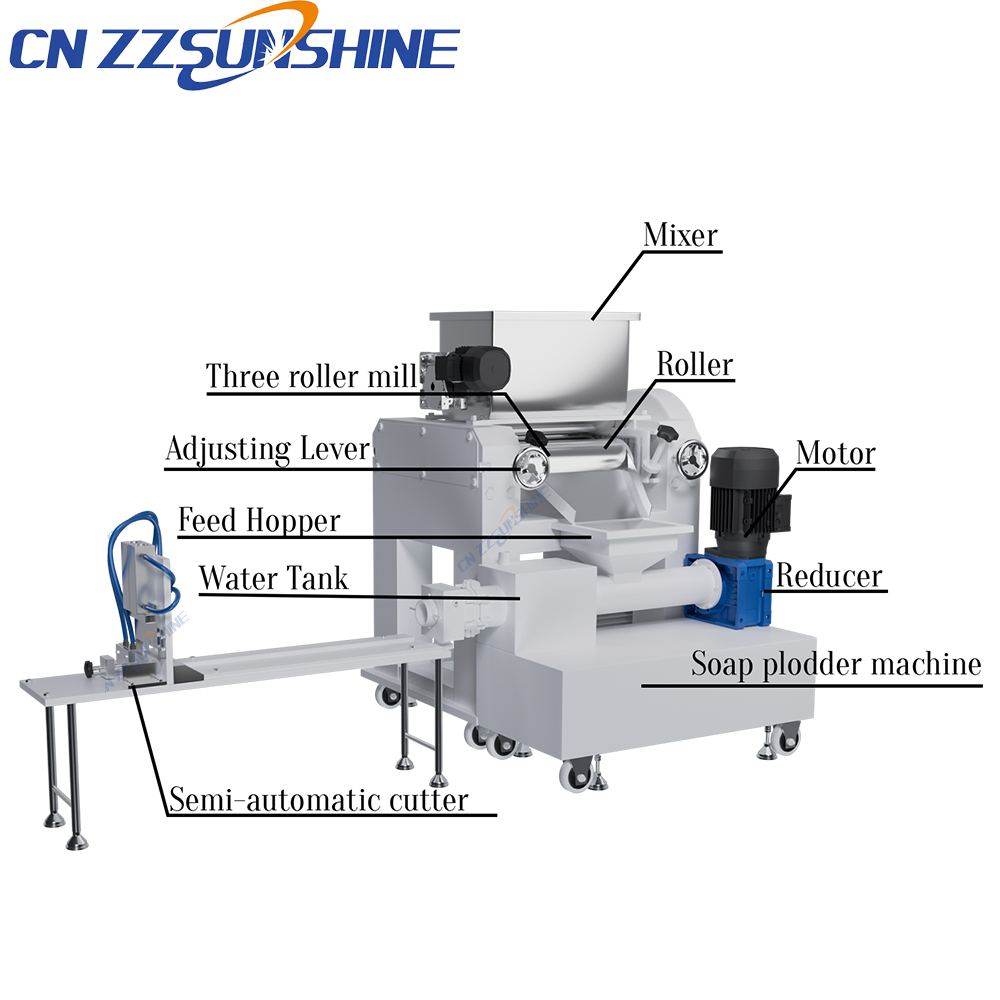

The core of this laundry soap making line integrates a robust soap mixer for homogenous blending of components. The mixed paste is then processed through a high-performance soap plodder (including vacuum plodder options) to refine texture and remove air pockets. Subsequent stages involve precision cutting using an electric washing soap cutter or pneumatic cutting machine, followed by shaping and stamping via a dedicated soap stamping machine. Finally, a film packaging machine ensures hygienic, attractive wrapping for the market.

This automatic soap production line minimizes manual intervention, boosting output and consistency significantly compared to semi-automatic or manual cutting machine setups. We offer factory direct solutions, including custom soap cutting machine options and OEM components like three roller grinding mills, tailoring the washing liquid production equipment or bath soap making machine line to your specific production volume and bar specifications. Invest in a solution built for efficiency and superior soap quality.