Crafting Quality: Inside the Soap Making Production Line

For manufacturers serious about producing high-quality bar soaps efficiently, understanding the core components of a modern soap making production line is essential. This integrated system transforms raw materials into finished bars through a series of precisely engineered stages.

The journey often begins at the saponification tank equipment plant, where fats or oils react with caustic soda to form soap base. This critical chemical process requires robust equipment designed for safety and consistent results. Following saponification, the soap base moves into refining stages, potentially utilizing equipment like an OEM three roller grinding mill for achieving a smooth, homogenous texture.

The heart of shaping the soap mass lies in the soap noodle making machine production line. Here, the refined soap is extruded through specialized dies, cooled, and cut into uniform pellets or noodles. This step is vital for ensuring even drying and subsequent processing. The noodles then enter the soap noodle dryer machine, a crucial component designed to reduce moisture content efficiently and uniformly, preparing the material for the final forming stages.

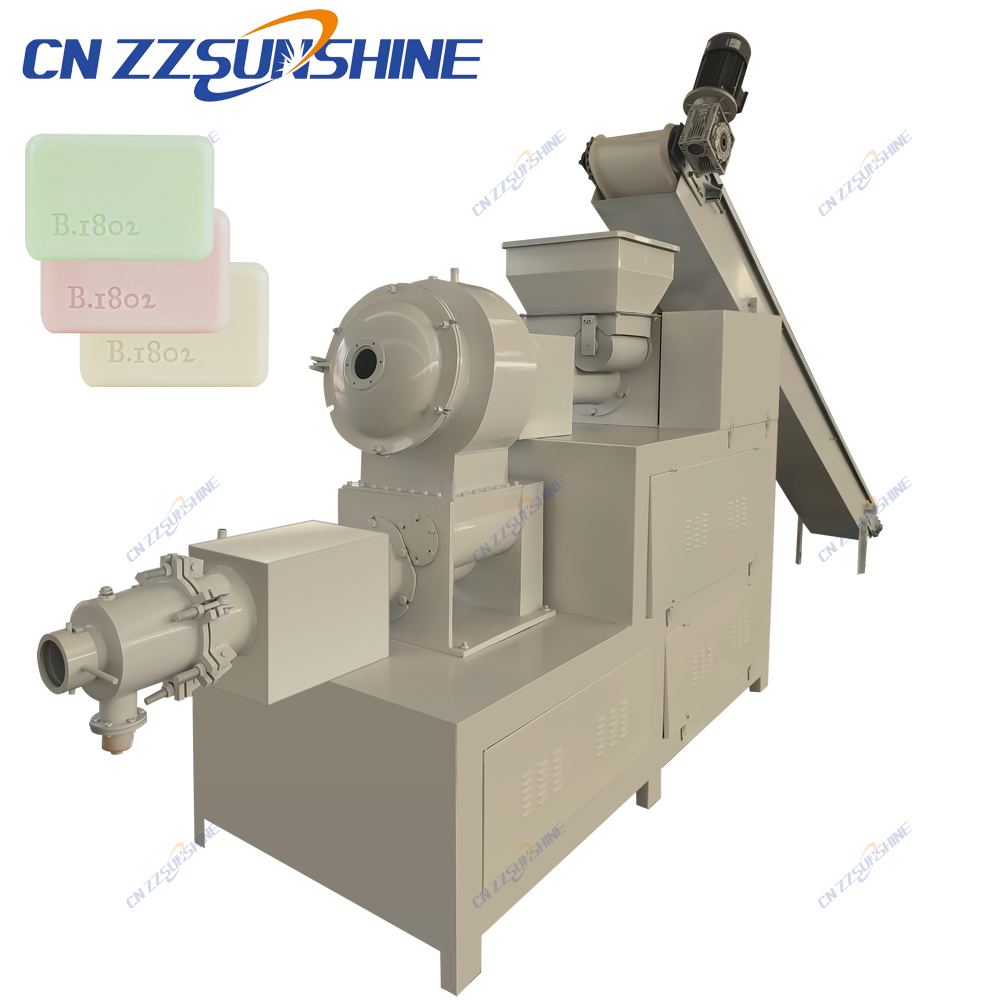

Once dried, the soap noodles are ready for compaction and shaping. This is where the soap plodder machine for bar soap comes into play. Operating under vacuum, a vacuum plodder removes air pockets, compresses the noodles, and extrudes a continuous, dense soap log. This log is then precisely cut into individual soap bars using an automatic block cutter machine. Options range from manual cutting machines to sophisticated electronic cutting machine or pneumatic cutting machine systems, depending on the production scale and automation level required.

The final steps focus on finishing and packaging. Soap stamping machines imprint logos and designs, while film packaging machines wrap the bars for retail. Whether building a dedicated laundry bar soap production line, a toilet soap finishing line, a beauty soap making line, or even a mini soap production line, selecting the right combination of machinery – such as reliable soap mixer units, efficient cutter systems, and appropriate automatic printer solutions – determines the line’s efficiency, output quality, and overall success. Investing in a well-integrated automatic soap production line ensures consistent, high-volume production of premium soap products.