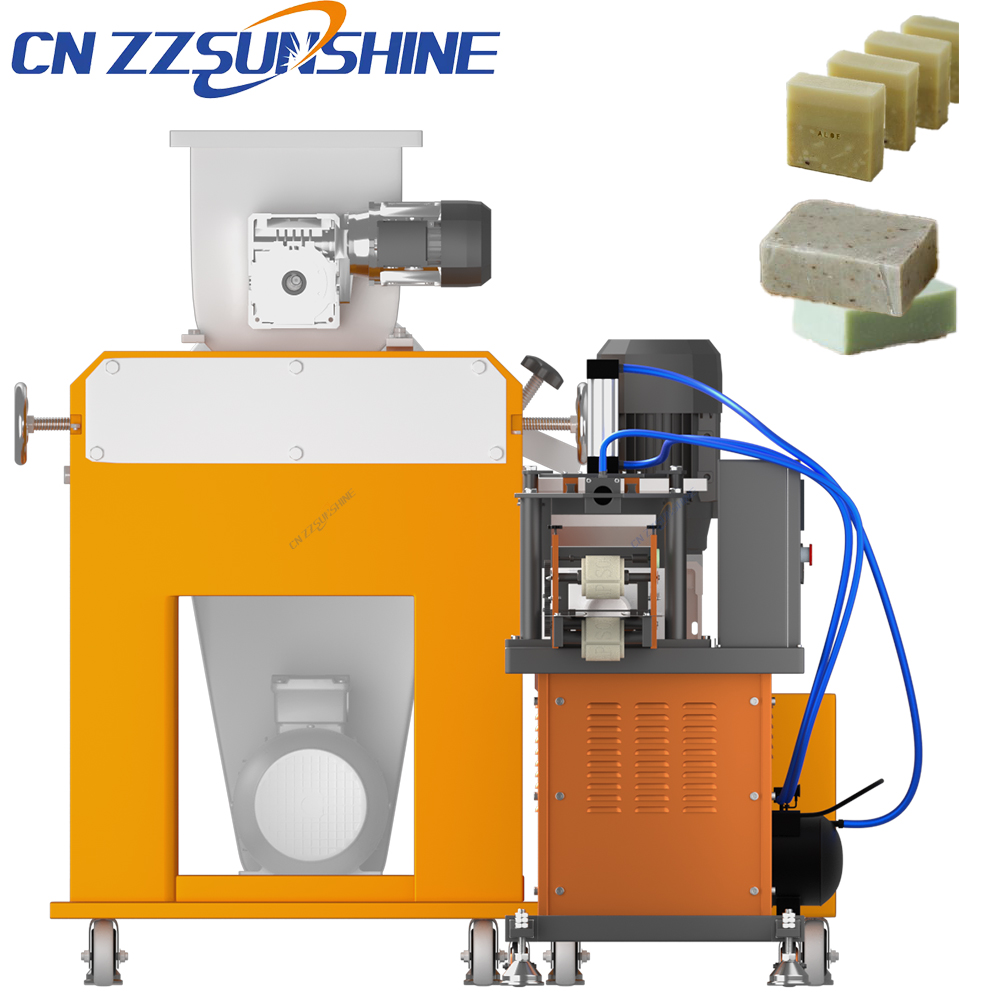

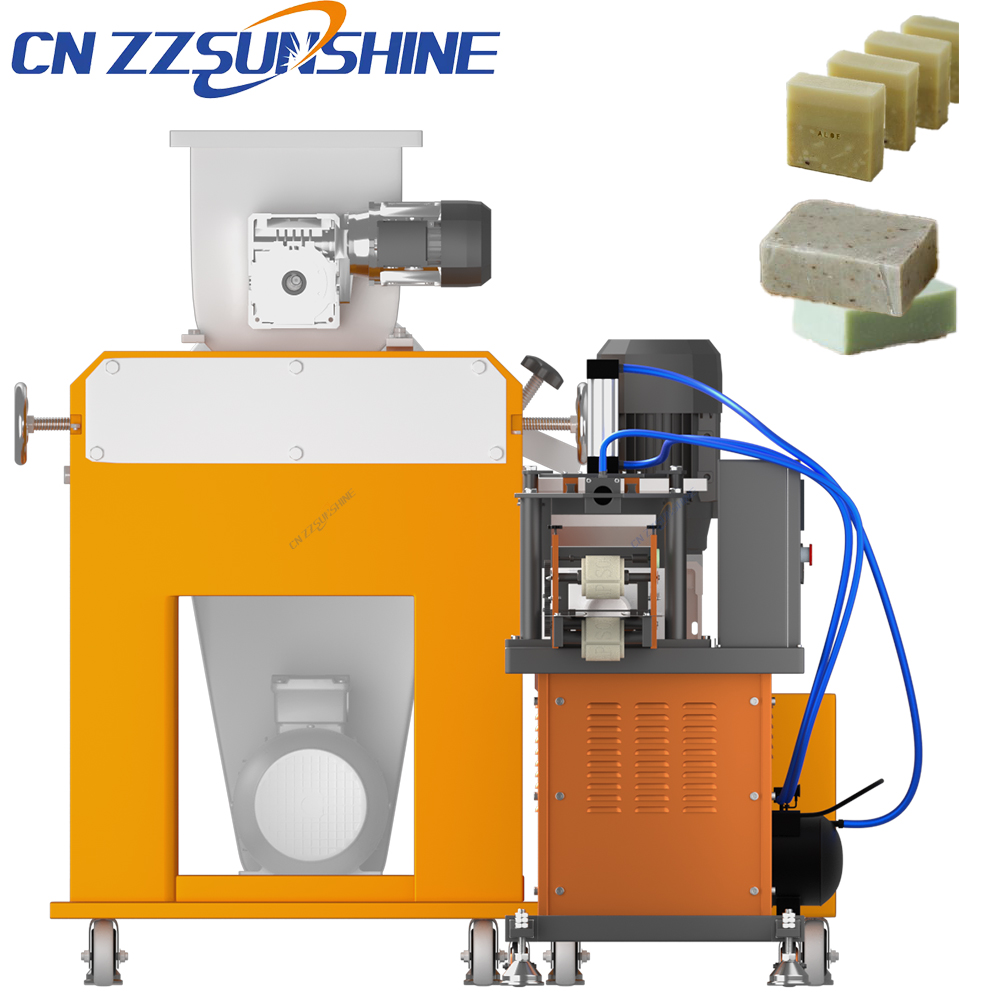

In today’s competitive soap industry, a well-designed soap making production line is essential for achieving high output and consistent quality in bar soap manufacturing. This integrated system typically includes key components like a soap mixer for blending raw materials, a vacuum plodder to eliminate air pockets and enhance density, and an automatic soap cutter for precise sizing. For instance, laundry bar soap production lines often incorporate a vacuum plodder to ensure uniform texture, reducing waste and improving shelf life. Similarly, beauty soap making lines leverage custom soap cutting machines to handle delicate formulations, while laundry soap making lines focus on durability with robust plodder machines. The automation streamlines processes, cutting labor costs by up to 40% and boosting daily production capacity. Moreover, modern setups like an automatic soap production line support scalability, allowing factories to adapt to custom orders without downtime. By investing in such efficient systems, manufacturers gain a competitive edge through faster turnaround and superior product consistency, ultimately driving higher profitability in global markets.

Soap Making Production Line: Revolutionizing Bar Soap Manufacturing Efficiency

Soap Making Production Line: Revolutionizing Bar Soap Manufacturing Efficiency

Posted Date:

By:

If you’re interested in our soap manufacturing equipment or would like to learn more about customized solutions tailored to your specific production needs, please fill out the inquiry form below with details such as your required capacity, soap type, level of automation, etc. As a professional manufacturer of soap machinery, we’re ready to provide you with comprehensive information and a competitive quotation—welcome to contact us!