Unlock Your Soap Production Potential: From Artisan Kits to Industrial Lines

The allure of handmade soap – unique shapes, luxurious lather, and personalized scents – captivates both hobbyists and entrepreneurs. Starting with a simple soap making kit featuring a soap bomb mold can ignite creativity. However, scaling production efficiently requires robust machinery. Whether you’re crafting delicate beauty bars or robust laundry soaps, the right soap making machine is key to consistent quality and volume.

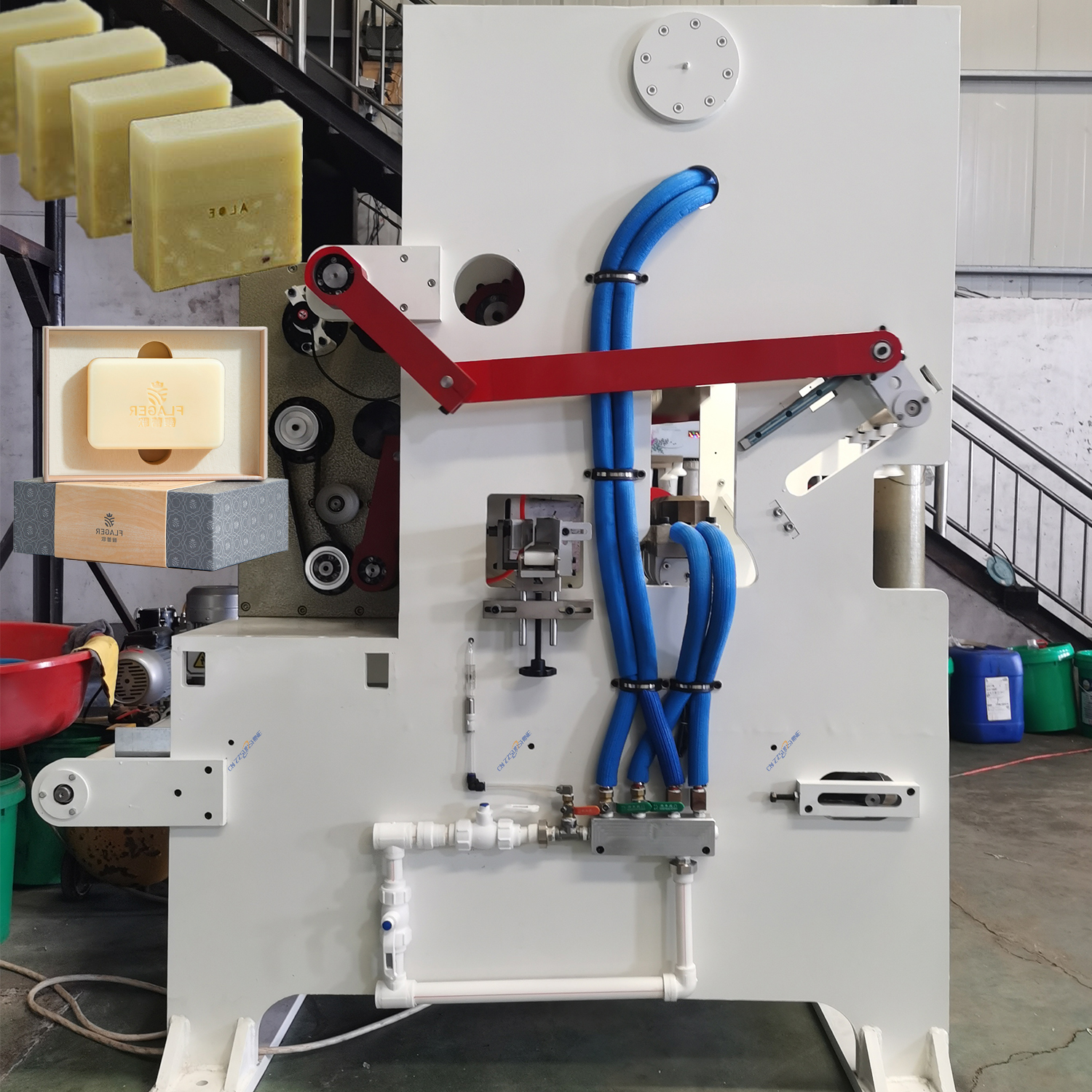

Transitioning from manual methods to automated processes significantly boosts output. A core component in any soap production line is the soap plodder machine. This vital equipment, especially a vacuum plodder, processes mixed soap base under pressure and vacuum. It removes air bubbles, ensuring a dense, smooth bar that won’t crumble. For bar soap production, whether toilet soap or laundry bar soap, the plodder’s extrusion quality is paramount.

Once extruded, the continuous soap log needs precise sizing. This is where cutting machines shine. Options range from manual cutting machines for small batches to highly efficient automatic block cutter machines. Electronic cutting machines or pneumatic cutting machines offer programmable precision, ensuring uniform bars with clean edges. For businesses seeking tailored solutions, a custom soap cutting machine can be designed to meet specific dimensions and throughput needs.

Further refinement comes with milling and finishing. An OEM three roller grinding mill finely refines the soap paste, creating a smoother texture ideal for high-end beauty soap making lines. Subsequent stages might involve a soap stamping machine for branding and a film packaging machine for attractive, protective wrapping. A complete toilet soap finishing line or laundry soap making line integrates these steps seamlessly.

For liquid products, dedicated washing liquid production equipment is essential. And for those entering the industry or expanding cautiously, a mini soap production line or semi-automatic printer offers a manageable starting point before investing in a full automatic soap production line with an automatic printer.

From the initial mixing in a soap mixer or mixing machine to the final stamped and packaged bar, each machine in the chain – the soap plodder, cutter, and beyond – plays a crucial role. Choosing the right combination, be it a compact setup or a comprehensive automatic soap production line, empowers you to meet market demands efficiently, turning creative soap concepts into thriving production realities.