Elevate Your Soap Production: Precision and Efficiency Combined

Creating high-quality soap bars demands more than just good ingredients; it requires precision equipment at every stage. For businesses seeking to enhance their soap making production line, integrating specialized machinery is key to achieving consistent results and boosting output.

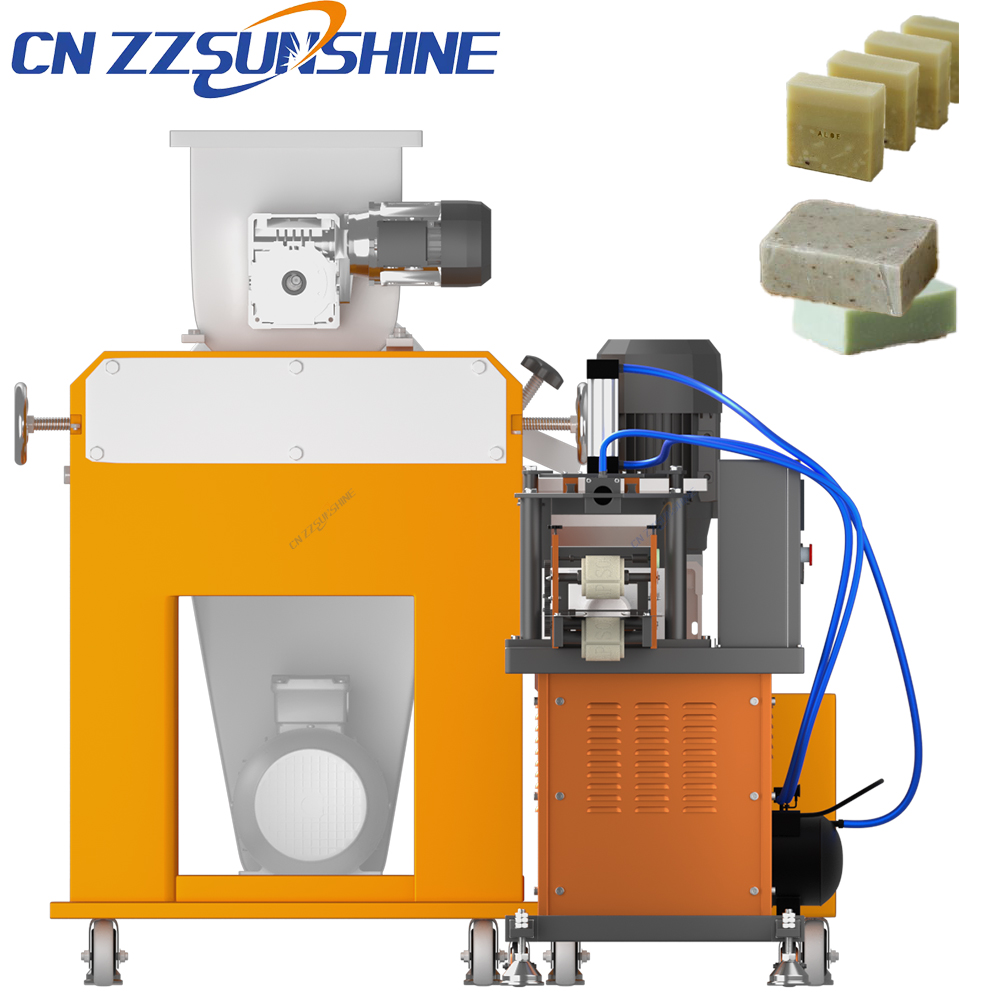

Focusing on the finishing stages, equipment like a soap embossing press machine or a hand soap stamping machine adds the final, professional touch that distinguishes your brand. These machines ensure crisp, clear logos and designs on each bar. When paired with an efficient soap cutter, particularly a pneumatic cutting machine, you gain reliable, clean cuts with minimal effort. The pneumatic bearing system offers smooth operation and durability.

This combination – precise stamping and cutting – is vital for any toilet soap finishing line or laundry bar soap production line. It streamlines the process from extrusion (using a vacuum plodder) to packaging, ensuring uniformity and reducing waste. For larger operations, an automatic soap production line incorporating these elements maximizes efficiency. Smaller setups or custom batches benefit immensely from versatile machines like a custom soap cutting machine.

Investing in the right finishing equipment, including a robust soap stamping machine and a dependable pneumatic cutter, directly impacts your product’s market appeal and production efficiency. Imagine achieving perfect bars, every time, with greater ease.