The Indispensable Lab Tool: Small Three Roll Mill Machines for Superior Soap Development

In the intricate world of soap making, achieving the perfect texture, color dispersion, and particle size is paramount. This is where precision grinding becomes non-negotiable, especially during the critical research and development phase. Enter the small three roll mill machine – a cornerstone piece of equipment designed specifically for laboratory use in soap making and other paste-like formulations.

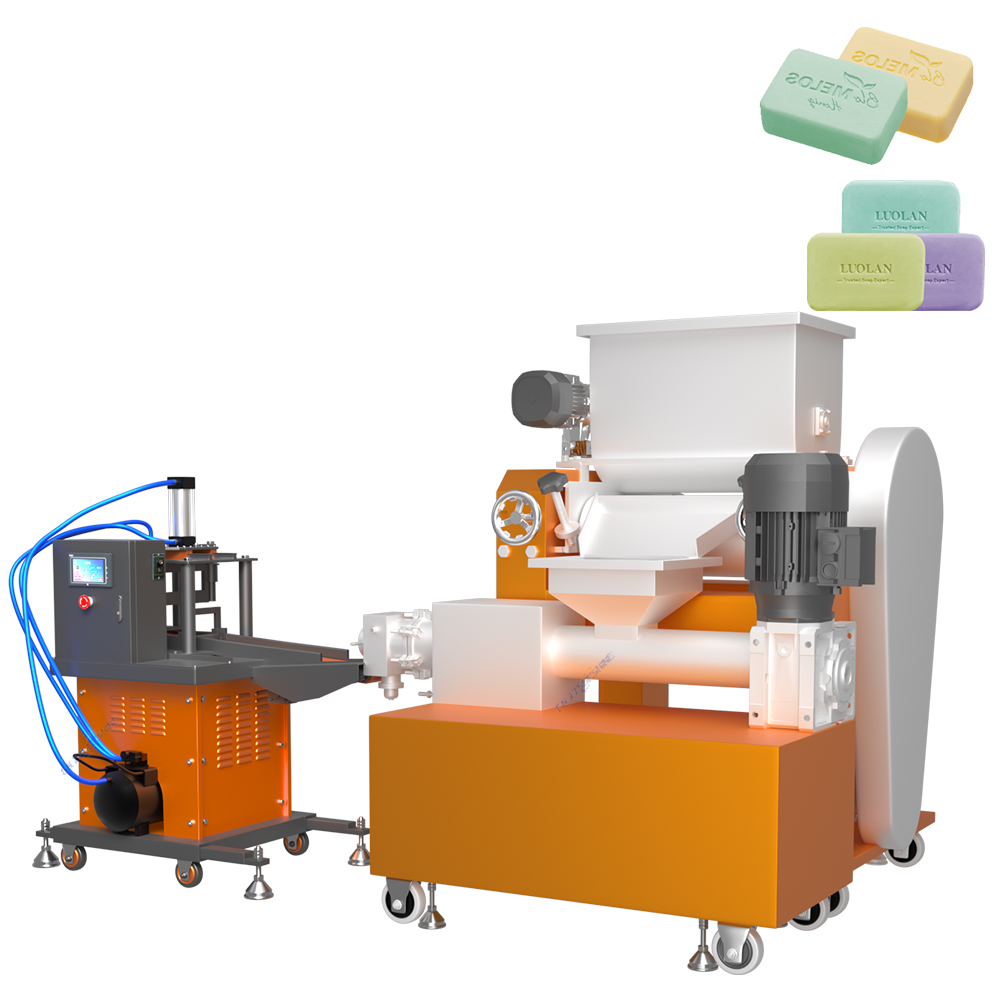

This compact yet powerful three-roller grinding mill operates on a simple principle: three horizontally positioned rollers rotate at different speeds, creating high shear forces. As the soap paste passes between these rollers, it is subjected to intense compression and shearing. This action effectively breaks down agglomerates, refines particle size, ensures uniform pigment dispersion (vital for vibrant bath soap making), and creates a smooth, homogenous mixture essential for high-quality bar soaps, whether for laundry or toilet applications.

For labs focused on developing new soap recipes or improving existing ones, the advantages of a dedicated small three roll mill are clear:

1. Precision Control: Adjustable roller gaps and speeds allow technicians to fine-tune the grinding process for specific formulations, achieving the exact consistency required.

2. Material Versatility: Beyond soap bases, these mills handle pigments, additives, and other viscous materials used in beauty soap making lines or custom formulations.

3. Quality Assurance: Consistent refinement at the lab stage prevents issues like graininess or uneven color in the final bar soap production line.

4. Scalability: Results achieved on a lab-scale mill provide reliable data for scaling up to larger soap making production lines, potentially integrating equipment like vacuum plodders, automatic block cutter machines, or soap stamping machines.

Modern laboratory three roll mills often feature robust construction, user-friendly controls, and options for different roller materials (like hardened steel or ceramic). They serve as the vital link between initial mixing (perhaps using a laboratory soap mixer) and the final shaping and finishing processes found in toilet soap finishing lines or laundry bar soap production lines. Whether working towards a fully automatic soap production line or a more flexible mini soap production line, starting with precise grinding in the lab is fundamental.

For businesses seeking tailored solutions, OEM three roller grinding mill options allow customization to fit specific R&D workflows. Investing in a high-quality small three roll mill ensures that the foundation of your soap – its smoothness and refinement – is perfected long before it reaches the cutter (be it manual cutting machine, electronic cutting machine, or pneumatic cutting machine) or the film packaging machine. It’s the unsung hero of impeccable soap development.