The Smart Choice: Compact Soap Production Lines for Big Results in Small Spaces

For entrepreneurs, boutique manufacturers, or businesses operating in venues with limited space, launching or scaling a soap production line often feels like an impossible dream. Traditional, large-scale soap making equipment demands significant floor space and capital investment – resources simply not available to everyone. But what if you could achieve professional-grade soap production, efficiently and cost-effectively, without needing a warehouse? That’s where the innovative concept of the Small Soap All-In-One Machine or Mini Soap Production Line truly shines.

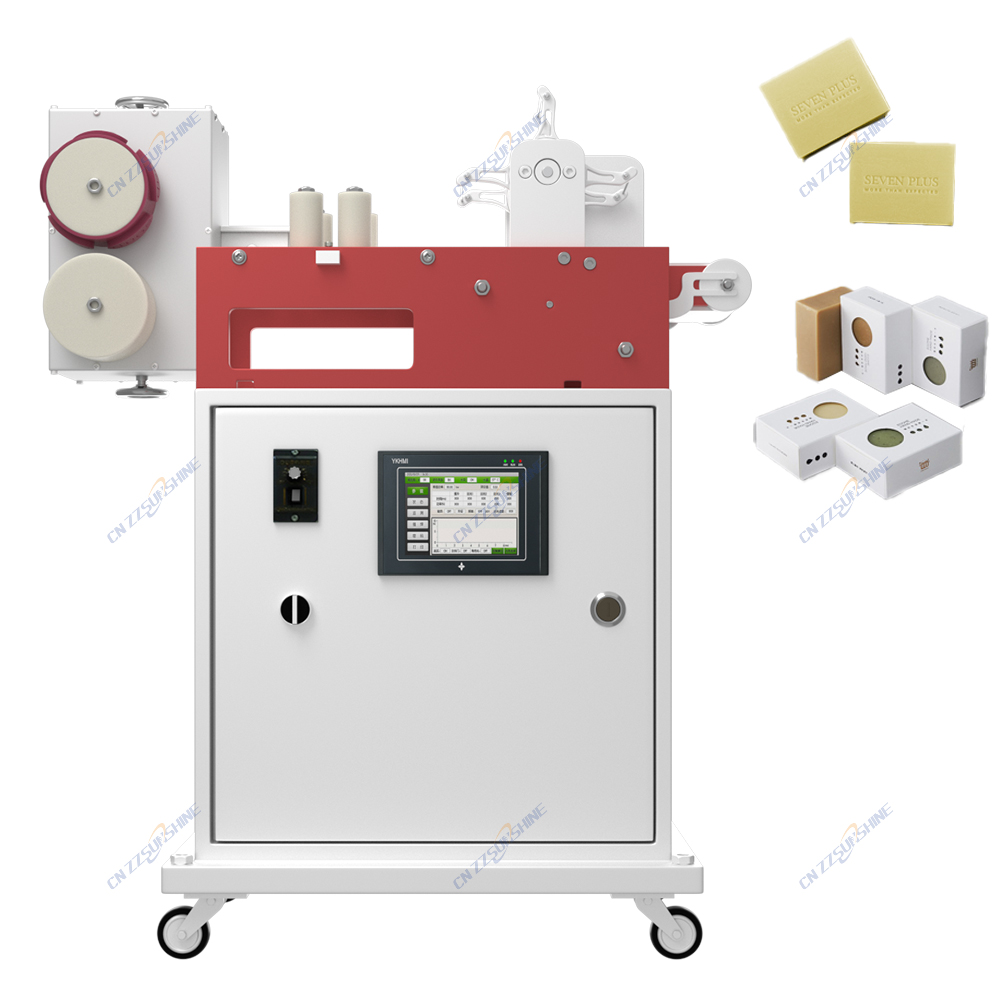

These compact production lines are engineered specifically for small venues. They combine essential soap-making processes into a remarkably small footprint. Think of it as a concentrated powerhouse: a core unit integrating a soap mixer for thorough blending of raw materials, followed by a soap plodder (often a vacuum plodder even in these compact versions) to extrude and homogenize the soap mass, removing air bubbles for a superior bar. Integrated cutter units – which could be electronic cutting machines, pneumatic cutting machines, or even manual cutting machines depending on the model and automation level – then slice the continuous soap log into precise individual bars. Some advanced models might even incorporate downstream equipment like a semi-automatic printer or soap stamping machine, and a film packaging machine for a complete, space-saving toilet soap finishing line or laundry bar soap production line.

Don’t mistake ‘small’ for ‘low output’. The genius of these soap making machines lies in their ability to deliver high production capacity relative to their size. Modern engineering allows efficient, continuous operation. While a massive industrial automatic soap production line might produce tonnes per hour, a well-designed Mini Soap Production Line can yield impressive volumes – perfect for fulfilling local market demand, boutique orders, or testing new product lines without massive overhead. For instance, a typical compact line might efficiently produce 15-20 kg of finished soap bars per hour within a very confined area.

Key Advantages of a Small Footprint Soap Line:

| Feature | Benefit | Example |

|————-|————-|————-|

| Minimal Space Requirement | Fits easily in small workshops, garages or dedicated corners | Occupies less than 10 square meters |

| Integrated Processes | Combines mixing, plodding and cutting in compact design | Vacuum plodder ensures high-quality extrusion |

| Impressive Output | Delivers substantial production relative to size | 15-20 kg/hour capacity |

| Cost Efficiency | Lower capital investment and operational costs | Ideal for startups and small businesses |

| Scalability | Allows business growth without massive infrastructure | Perfect for testing new product lines |

The benefits are clear: significantly lower capital investment compared to full-scale industrial lines, drastically reduced operational costs (especially rent and utilities), and the agility to start production or scale incrementally. Whether you’re crafting luxurious beauty soap, robust laundry soap, or specialty bars, a compact, high-capacity soap making production line offers the practical solution you’ve been searching for. It’s the ideal solution for turning your soap-making vision into a thriving, space-smart reality.