Your Home Soap Studio: Compact, Easy & Professional Results

Dreaming of crafting beautiful, artisanal soaps right from your kitchen counter or home workshop? The idea is captivating – creating unique bars with custom scents, colors, and nourishing ingredients. But for beginners and small-scale enthusiasts, the perceived complexity and size of traditional soap making equipment can feel like an insurmountable barrier. Enter the solution: the Small Soap All-In-One Machine. This compact marvel is designed specifically to make soap production line operations accessible, manageable, and truly enjoyable for home crafters and small businesses.

Why Go Small?

Forget the intimidating industrial setups. A Mini Soap Production Line, centered around an easy-to-operate machine, offers significant advantages:

Space Savvy: Perfectly suited for home studios, garages, or small workshops.

Beginner Friendly: Intuitive controls and simplified processes lower the learning curve dramatically. Easy to operate is its core principle.

Cost Effective: A smart investment compared to sprawling industrial lines, offering professional results without the massive overhead.

Versatility: Craft a variety of bar soaps – luxurious bath bars, effective laundry soaps, or specialty beauty soaps.

Unpacking the Essentials: Your Compact Lineup

While truly “all-in-one” machines handle multiple steps, understanding the core components of a small-scale soap making machine for home is helpful:

1. Mixing Perfection (The Heartbeat): It all starts here. A robust soap mixer or compact mixing machine is essential. It thoroughly blends oils, lye solution, fragrances, and additives into a homogeneous trace. Consistent mixing is foundational for quality soap. For specific formulations, an OEM three roller grinding mill might be integrated for super-fine milling of additives, though this is more common in larger setups.

2. Refining & Forming the Bar (The Transformer): This is where the magic of bar formation happens. A small soap plodder, often a vacuum plodder, is key. It compresses the mixed soap mass, removes air pockets (crucial for a smooth, long-lasting bar), and extrudes a continuous, solid log of soap. This step determines the bar’s density and texture. The soap plodder machine for bar soap is the workhorse of this stage.

3. Cutting to Size (Precision Finishing): Your extruded soap log needs to be cut into individual bars. This is where compact cutters shine. Options range from simple manual cutting machines to more efficient electric washing soap cutter or pneumatic cutting machine models. An automatic block cutter machine offers hands-off precision for higher volume, but even semi-automatic or manual options provide excellent results for home lines. Think custom soap cutting machine designed for smaller logs.

Beyond the Core: Adding Polish (Optional but Impactful)

Want truly professional touches? Consider adding:

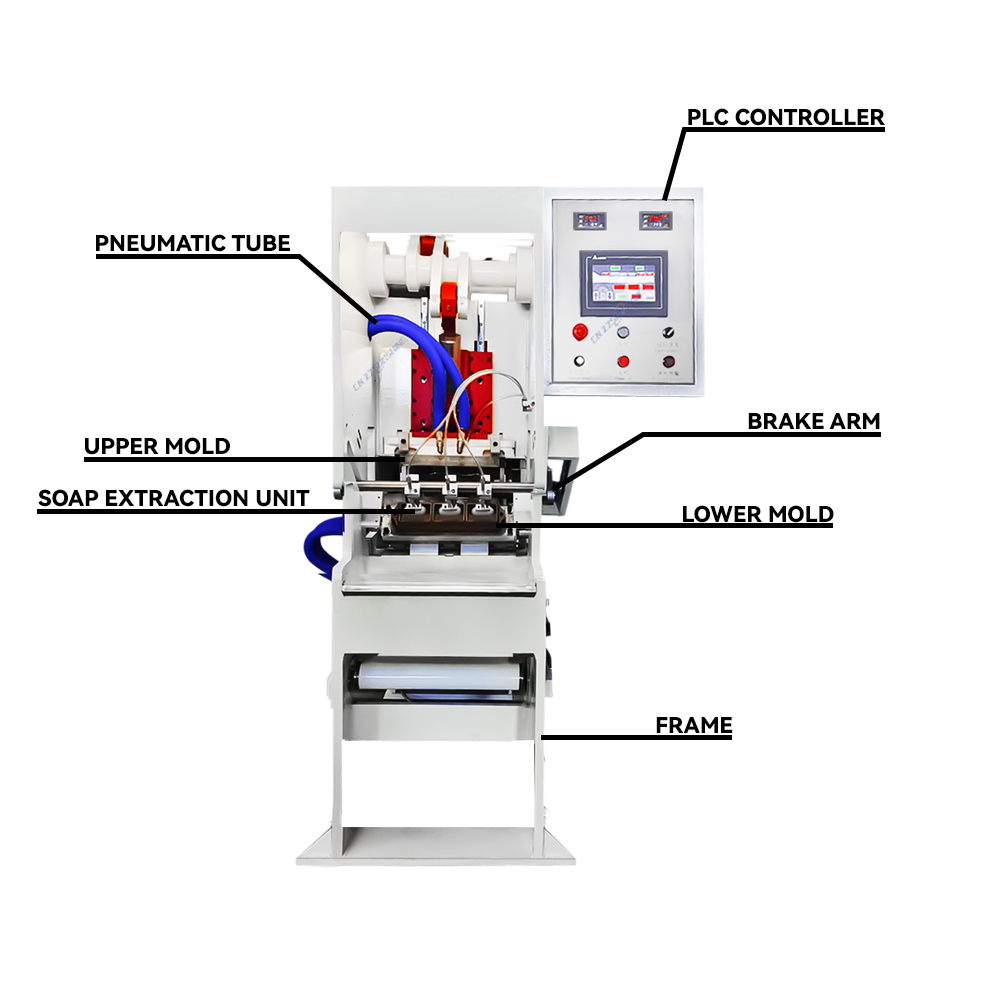

Stamping: A semi-automatic printer or soap stamping machine imprints your logo or design onto each bar.

Packaging: A simple film packaging machine can neatly wrap bars for sale or gifting.

The Allure of Integration: The True Small Soap Production Line

The beauty of the Small Soap All-In-One Machine concept lies in its integration. Imagine a single, compact unit that efficiently handles the core processes – mixing, refining (plodding), and extrusion – significantly reducing the footprint and complexity. This integrated approach embodies the easy to operate suitable for beginners soap production line ethos. It minimizes equipment juggling and streamlines your workflow.

Why Choose a Dedicated Home Soap Making Machine?

While tempting to adapt kitchen tools, dedicated soap making machinery offers:

Consistency: Achieve professional-grade results batch after batch.

Efficiency: Save significant time and effort compared to manual methods.

Safety: Designed to handle soap paste safely and effectively.

Scalability: Grow your hobby or small business without immediately needing a large automatic soap production line.

Ready to Craft Your Soap Story?

Don’t let the dream of crafting beautiful, handmade soap remain just a dream. A soap making machine for home, especially a compact soap production line designed for simplicity, unlocks your creative potential. Whether it’s a laundry bar soap production line for eco-friendly cleaning or a beauty soap making line for luxurious skincare, the right small-scale equipment makes it achievable, efficient, and deeply rewarding. Explore options designed for beginners and home use – your perfect bar of soap awaits.