Beyond Handmade: The Rise of Compact Soap Production Lines for Modern Manufacturers

The demand for quality bar soap – be it for laundry, toilet, or beauty applications – remains robust. Yet, for small to medium-scale manufacturers, scaling beyond labor-intensive handmade methods presents significant challenges. Enter the Small Complete Toilet Laundry Bar Soap Plodder Extruder Maker Production Line Making Machine. This integrated solution represents a leap forward, offering efficient, consistent, and professional-grade production in a surprisingly compact footprint.

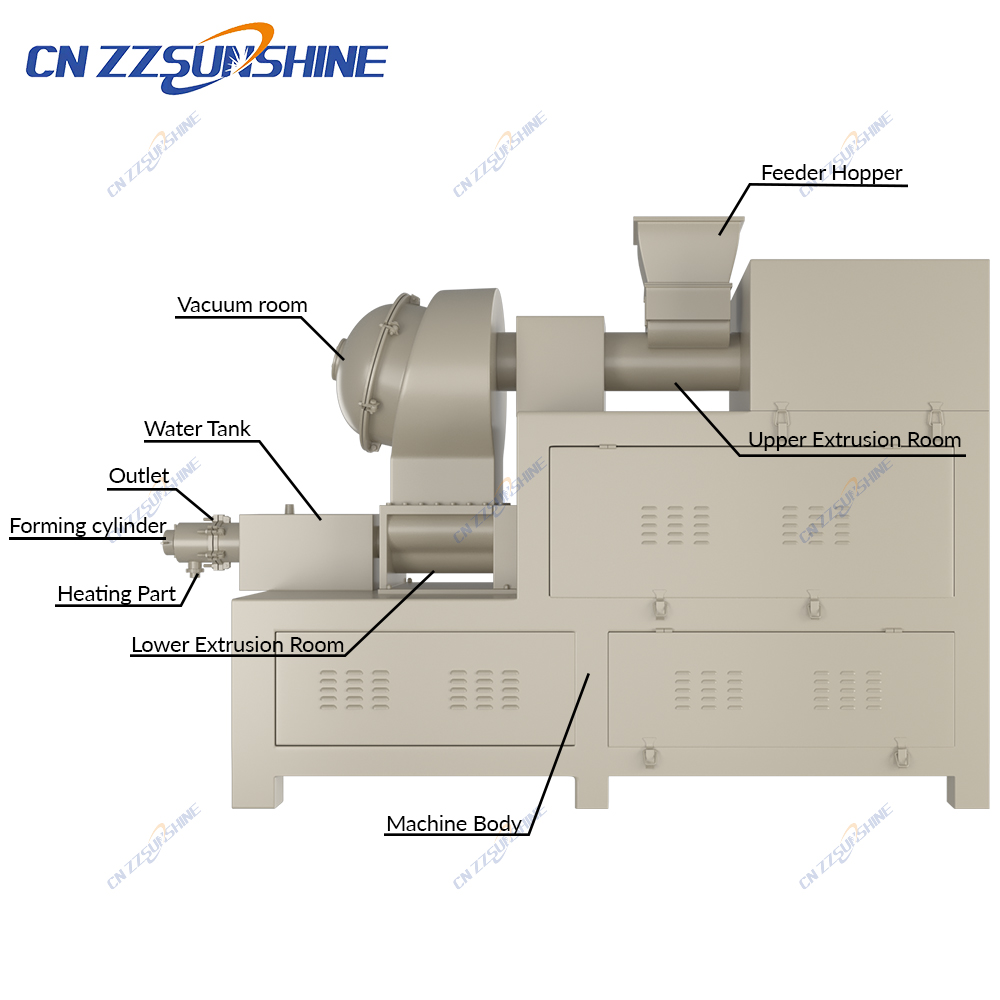

We understand that starting or upgrading a soap making production line can be daunting. The key lies in selecting the right combination of machinery tailored to your specific output goals and product types. A core component of any efficient laundry bar soap production line or toilet soap finishing line is the soap plodder machine for bar soap. This vital equipment, often a Vacuum plodder, works by continuously mixing, compressing, and extruding the soap base. It removes air pockets and ensures a dense, uniform texture crucial for the final bar’s quality and longevity. Paired with a robust soap mixer or Mixing machine, it guarantees homogeneous blending of ingredients.

The extruded soap log then moves to cutting. While Manual Cutting Machine options exist, efficiency demands automation. An automatic block cutter machine or Electric washing soap cutter provides precise, high-speed cutting with minimal waste, delivering consistently sized bars ready for the next stage. For those requiring even finer control, Electronic Cutting Machine or Pneumatic Cutting Machine options offer advanced precision.

Further refinement often involves milling. An OEM three roller grinding mill can be integrated for fine refining the soap base before plodding, particularly important for premium toilet soap finishing line or beauty soap making line products. Finally, the finishing touches: a Soap Stamping Machine imparts branding, while a Film Packaging Machine efficiently wraps the bars for market. Together, these components form a complete system.

Why consider such a line? The benefits are compelling:

Consistency & Quality: Automated processes eliminate human error, ensuring every bar meets exact specifications.

Efficiency & Scale: Dramatically increase output compared to manual methods, meeting market demand effectively.

Cost-Effectiveness: Reduce long-term labor costs and material waste.

Flexibility: Many lines, including Mini Soap Production Line configurations, can be adapted for different soap types (laundry, toilet, beauty) with adjustments.

Whether you’re establishing a new laundry soap making line or upgrading an existing bath soap making machine setup, investing in an integrated, Automatic soap production line is a strategic move. Look for solutions offering reliable core components like the soap plodder and automatic block cutter machine, with options for custom soap cutting machine designs or OEM mills to perfectly match your needs. Explore semi-automated options like a Semi-automatic Printer if full Automatic Printer integration isn’t initially required.

For manufacturers seeking a competitive edge, embracing compact, automated soap making machine technology is no longer a luxury – it’s a necessity for sustainable growth and consistent product excellence. Discover how a tailored production line can transform your soap manufacturing capabilities.