Streamline Your Soap Production: Simple Maintenance Small Lines for Laundry & Bath Bars

For entrepreneurs and small manufacturers seeking efficient, cost-effective solutions, a compact soap making production line offers the perfect entry point. Focusing on laundry soap making line and toilet soap finishing line capabilities, these systems prioritize ease of operation and straightforward maintenance.

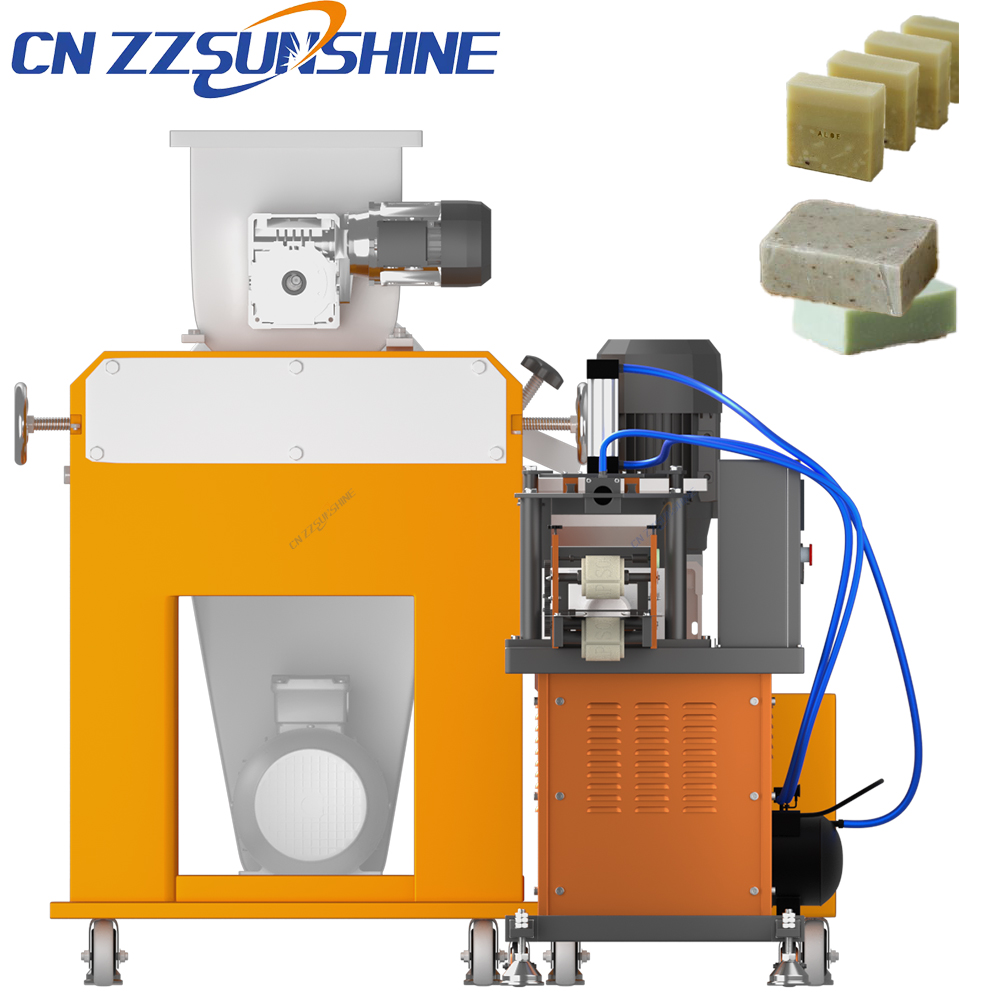

A core soap plodder machine for bar soap, often a vacuum plodder, ensures dense, homogenous extrusion for both laundry bar soap production line outputs and higher-quality bath soap making machine products. This is typically preceded by a robust soap mixer or mixing machine for thorough blending of fats, oils, and caustics. Precision cutting is handled by a reliable cutter, potentially an Electric washing soap cutter or pneumatic cutting machine, delivering consistent bar sizes. For specialized needs, a custom soap cutting machine or automatic block cutter machine can be integrated. Key refining steps might involve an OEM three roller grinding mill.

These Mini Soap Production Line setups are ideal for launching beauty soap making line ventures or expanding existing capacity. While often Semi-automatic, components like an Automatic soap production line printer (Automatic Printer) or Soap Stamping Machine enhance efficiency. Final packaging can be managed with a basic Film Packaging Machine.

The beauty lies in scalability and customization. Manufacturers often offer OEM options, allowing you to tailor the soap making machine configuration – from the initial mixing machine to the final cutter – precisely to your laundry bar soap production line or toilet soap finishing line requirements. Invest smartly for quality and growth.