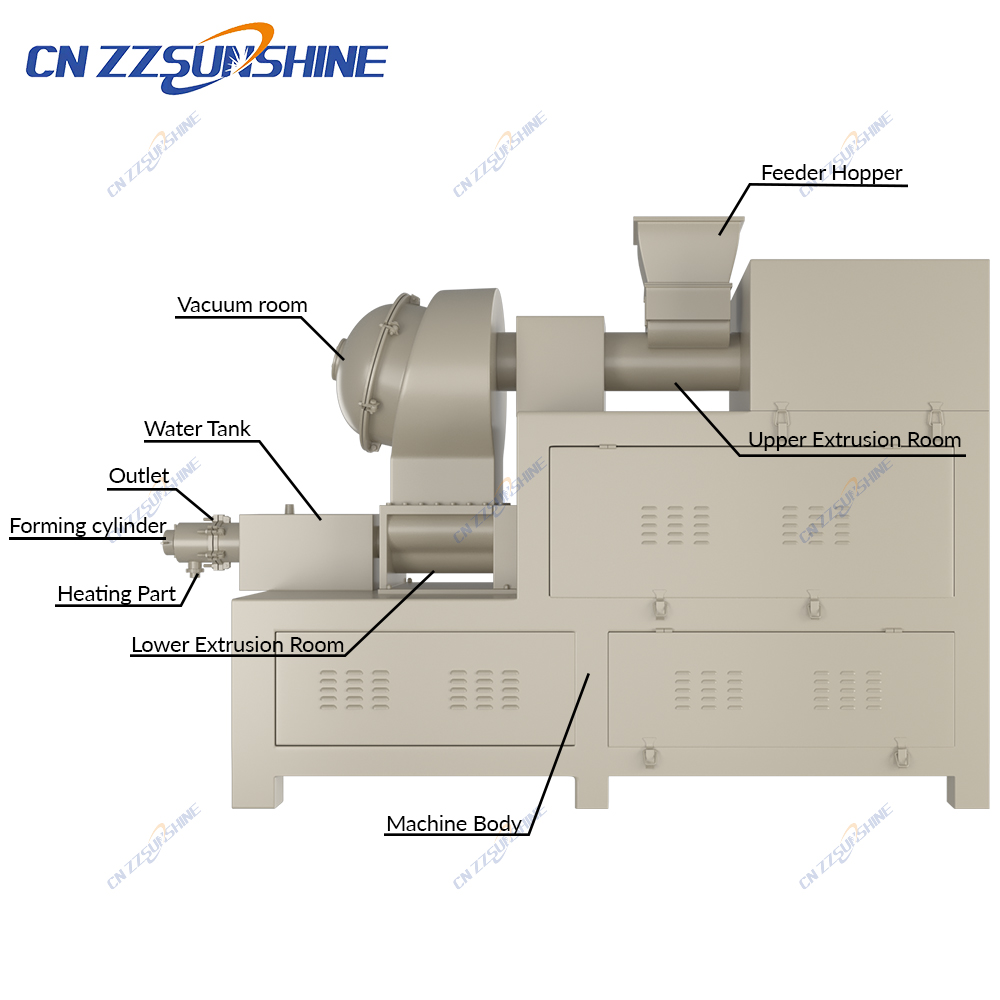

In today’s fast-paced manufacturing world, an automatic soap production line stands as a cornerstone for industries aiming to boost efficiency and product quality. This integrated system streamlines the entire process from raw material mixing to final cutting, ensuring consistent output for diverse applications like laundry bar soap production lines and beauty soap making lines. Key components include a high-performance soap mixer for uniform blending of fats and lye, a vacuum plodder that removes air bubbles to create dense, long-lasting bars, and an electric washing soap cutter for precise sizing without manual intervention. By incorporating a vacuum plodder for bar soap, manufacturers achieve superior texture and durability, while an automatic soap cutter machine reduces waste and enhances safety in high-volume settings.

The advantages of adopting such a line are compelling: it slashes labor costs by up to 50%, increases throughput with minimal downtime, and supports customization through OEM soap machinery solutions. For instance, in a bath soap making machine setup, the integration of a soap plodder ensures smooth extrusion for premium finishes, catering to both toilet soap finishing lines and industrial-scale operations. Moreover, with features like energy-efficient motors and automated controls, this system adapts seamlessly to varying recipes, from hard laundry soaps to gentle beauty variants. As global demand for hygienic products surges, investing in a custom soap production line not only future-proofs facilities but also drives sustainability by optimizing resource use. Ultimately, the shift to automation, exemplified by a reliable automatic soap production line, empowers factories to meet stringent quality standards while scaling production affordably.