Achieve Peak Efficiency in Your Soap Manufacturing Operations

Investing in a professional soap making production line is essential for manufacturers aiming for consistent quality and high-volume output. Whether your focus is laundry bar soap production line or a toilet soap finishing line, selecting the right core equipment makes all the difference.

The process typically begins with robust mixing machines for homogenous blending of fats, oils, and caustic soda. Following saponification, a high-performance soap plodder machine for bar soap is crucial. This unit refines the soap mass, removing air and moisture to create a smooth, dense extruded log. For producers requiring exceptionally fine texture, integrating an OEM three roller grinding mill into the line before the plodder delivers superior results.

The extruded soap log then moves to cutting. An automatic block cutter machine offers precision and speed, transforming the continuous log into individual bars. For businesses seeking flexibility, a custom soap cutting machine allows for tailored bar sizes and shapes. Modern electric washing soap cutter or pneumatic cutting machine options provide reliable, clean cuts with minimal waste.

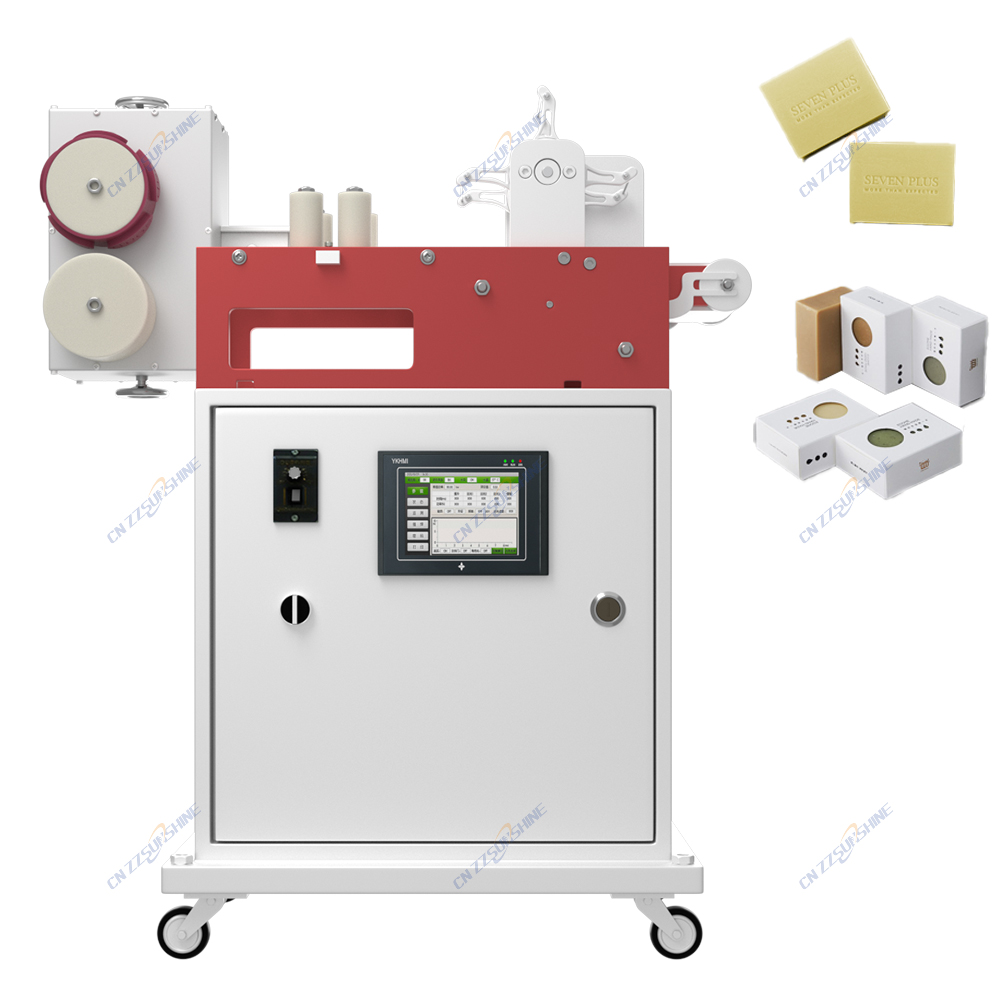

Completing the line, soap stamping machines and film packaging machines add the final branding and protection. Integrating these components – from the initial soap mixer through to packaging – creates a seamless automatic soap production line, maximizing throughput and minimizing labor costs. For specialized applications like beauty soap making lines, specific refining and finishing equipment ensures premium product quality.

Choosing durable, well-engineered machinery like a Professional Top Brand Soap Making Machine, a Complete Laundry Soap Making Machine, or a Good Quality Bar Soap Cutting Machine Cutter is an investment in the reliability, efficiency, and ultimate success of your soap manufacturing business.