Unlock Your Soap Crafting Potential: Essential Machines for the Small Business Artisan

For the passionate small business owner crafting laundry bars, elegant toilet soaps, or luxurious bath soaps, the journey from raw materials to a beautifully finished product requires precision and efficiency. Scaling beyond handcrafted batches often demands reliable machinery that fits within a compact workshop and budget. This is where targeted equipment, like a dedicated Professional Stainless Steel Laundry Soap Mixing Machine, a precise Toilet Soap Cutting Machine, or a versatile Bath Soap Maker, becomes invaluable. These machines are not just tools; they are the backbone of a consistent, high-quality, and scalable small soap making machine operation.

The Heart of Consistency: Your Mixing Machine

Achieving a uniform, high-quality soap base is paramount. A stainless steel soap mixer is designed specifically for this crucial stage. Constructed from durable, food-grade stainless steel, it ensures hygiene and prevents contamination, essential for products applied to the skin. Whether you’re blending fats, oils, lye, and additives for laundry soap making line formulations or creating more delicate toilet soap finishing line bases, this soap mixing machine works efficiently. Its robust design handles the often thick and viscous soap mixtures, ensuring thorough incorporation of ingredients. This results in a homogenous paste, providing a solid foundation for the subsequent refining and shaping processes. For businesses focusing on bath soap making machine production, a good mixer is the first step towards achieving that smooth, luxurious lather consumers expect.

Precision Cutting for Perfect Bars

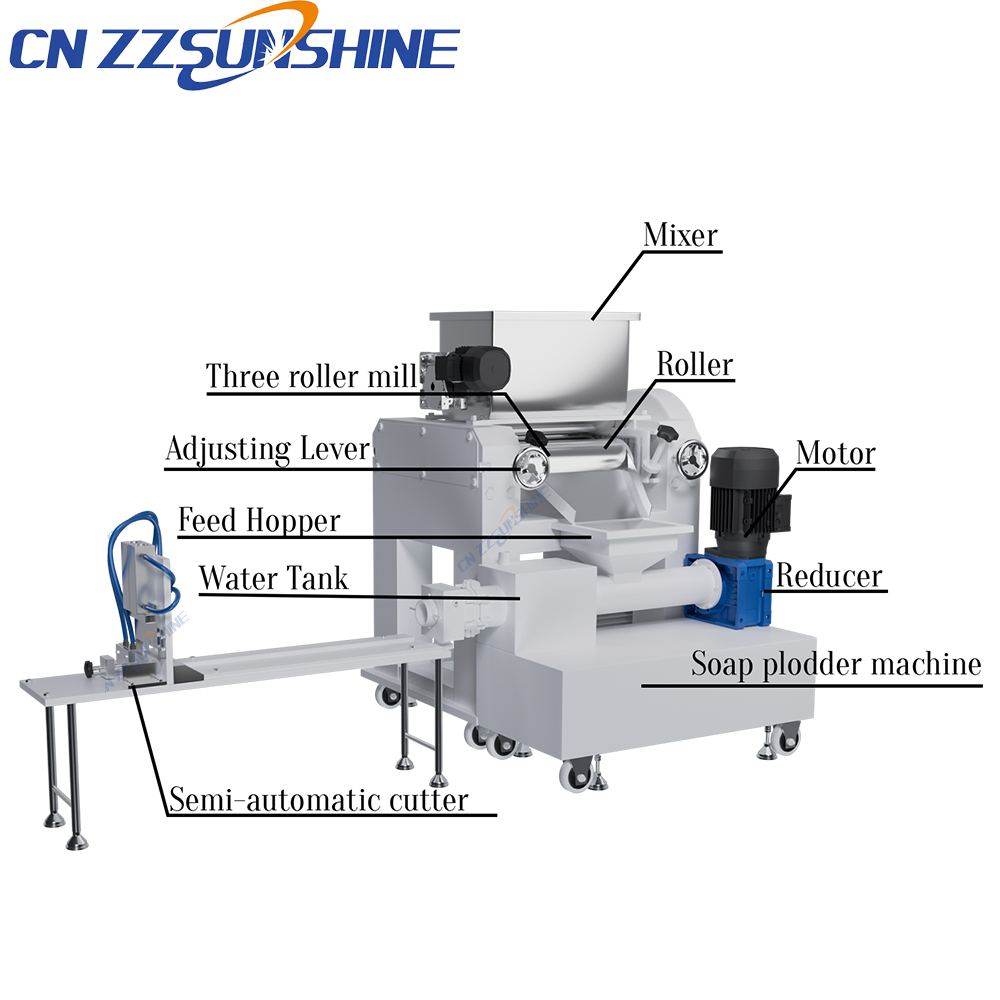

Once your soap base is mixed and refined (often using equipment like a soap plodder machine for bar soap to extrude a smooth, dense log), precise cutting is essential. A dedicated soap cutting machine transforms the continuous soap log into individual bars of exact dimensions. Options range from manual cutting machines for very low volume or artisanal batches to highly efficient automatic block cutter machines. For the small business looking to enhance productivity without overwhelming complexity, an electric washing soap cutter or a pneumatic cutting machine offers a practical middle ground. These provide consistent cuts with minimal effort, ensuring every bar meets your quality standards, whether it’s a hefty laundry bar or an elegant guest toilet soap. Investing in a reliable cutter eliminates sizing inconsistencies and significantly speeds up production.

Building Your Efficient Production Flow

While individual machines like the soap mixer and soap cutter are vital, integrating them into a cohesive workflow maximizes efficiency. For many small businesses, a Mini Soap Production Line offers the perfect solution. This might combine a compact soap plodder for extrusion, a simple Electronic Cutting Machine, and potentially a Semi-automatic Printer for basic stamping. This setup provides a significant upgrade from purely manual processes, boosting output while maintaining control over quality. If space and budget allow, stepping up to a more integrated Automatic Soap Production Line could include a vacuum plodder for superior deaeration and bar density, an automatic printer, and even a film packaging machine for streamlined wrapping. The beauty lies in customization; you can start with core machines like the stainless steel mixing machine and cutting machine, and gradually add components like a soap stamping machine or three roller grinding mill as your business grows.

Why Invest in Professional Small-Business Machines?

Incorporating a Professional Stainless Steel Laundry Soap Mixing Machine, a precise Toilet Soap Cutting Machine, or a tailored Bath Soap Maker setup delivers tangible benefits:

Enhanced Quality & Consistency: Machines deliver uniformity in mixing, extrusion, and cutting that is difficult to achieve manually, ensuring every bar meets your brand standards.

Increased Productivity: Automating repetitive tasks like cutting or basic stamping frees up valuable time for creativity, marketing, and business growth.

Scalability: Designed for small footprints, these machines allow you to increase output significantly without requiring a massive factory space.

Professional Results: Precision-cut, well-mixed, and consistently stamped soaps project a professional image that builds consumer trust.

Hygiene & Safety: Stainless steel construction and automated processes minimize direct handling, improving hygiene and operator safety.

For the ambitious small soap maker aiming to elevate their craft and business, investing in the right soap making machine technology is not an expense—it’s a strategic step towards sustainable growth and professional-quality products. Whether you start with a core soap mixer and cutter, or envision a compact automatic soap production line, these tools empower you to create exceptional soaps efficiently and reliably.