Crafting Quality: Your Guide to Small-Scale Professional Soap Production Lines

For entrepreneurs and established businesses alike, stepping into or expanding soap manufacturing requires efficient, reliable equipment. Investing in a Professional Soap Making Machine Production Small Line offers the perfect balance between capability and manageable scale. These compact yet robust systems are designed to handle the production of various soap types – from luxurious beauty soap making lines to essential laundry bar soap production lines and efficient toilet soap finishing lines – without demanding excessive space or capital.

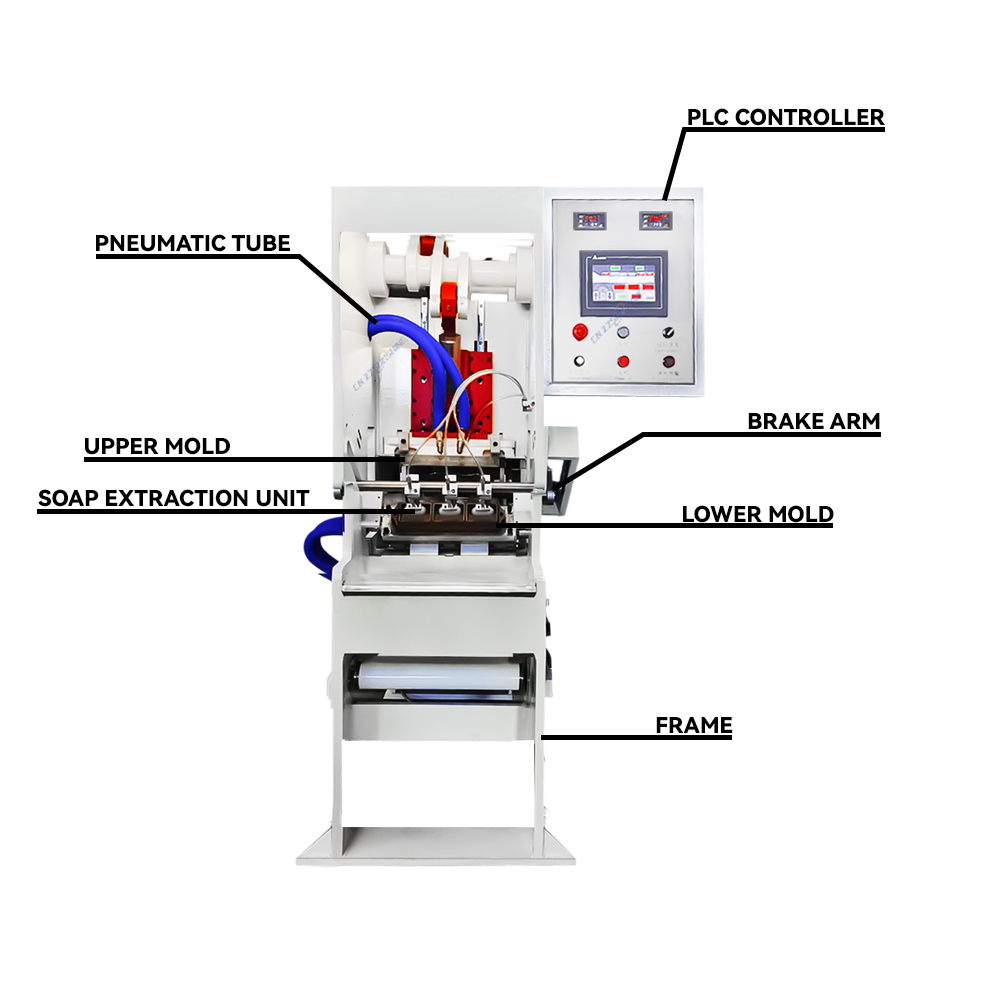

The core of any effective soap making production line, regardless of size, lies in its key components. A powerful soap mixer or mixing machine ensures the homogenous blending of fats, oils, lye, and additives, forming the perfect soap base. Following mixing, the critical refining stage often involves an OEM three roller grinding mill to achieve a smooth, consistent texture, essential for premium bar soaps. The heart of bar soap shaping is the soap plodder machine for bar soap, frequently enhanced by a Vacuum plodder to remove air pockets, resulting in a denser, higher-quality bar with better lather and longevity.

Shaping and finishing are where versatility shines. A custom soap cutting machine or automatic block cutter machine precisely sizes the extruded soap log. Options range from Manual Cutting Machines for very low volumes to Electric washing soap cutters, Electronic Cutting Machines, or Pneumatic Cutting Machines for faster, more automated lines. After cutting, branding is applied using equipment like a Semi-automatic Printer or fully Automatic Printer. Finally, the Soap Stamping Machine imparts the distinctive shape and design, while a Film Packaging Machine ensures the finished product is protected and presented professionally.

The beauty of a Mini Soap Production Line or Automatic soap production line configured for smaller outputs is its adaptability. Manufacturers can tailor the equipment selection to specific needs – perhaps focusing on bath soap making machines with intricate stamping or prioritizing high-volume laundry soap making lines with efficient cutting and packaging. Whether you require a core soap plodder, a specific cutter type, or integrated Washing Liquid Production Equipment for diversified output, suppliers often offer extensive customization and OEM support.

Choosing the right soap making machine setup is crucial. A well-designed Automatic Soap Production Line for smaller-scale operations maximizes efficiency, minimizes waste, and ensures consistent product quality. It allows businesses to respond flexibly to market demands, experiment with new formulations in the beauty soap making line, or efficiently produce staple goods like laundry bars. By focusing on core components like the soap mixer, soap plodder, and appropriate cutting and finishing tools, businesses can establish or upgrade their production with confidence.

Ready to upgrade your soap production? Explore the possibilities of a compact, professional line designed for quality and efficiency.