The Essential Machinery for Streamlined Soap Manufacturing: Investing in Efficiency and Quality

Building a successful soap manufacturing business hinges on more than just great formulations; it demands a robust and efficient production line. Selecting the right core equipment is paramount to achieving consistent quality, high output, and competitive operational costs. This article focuses on three critical machines forming the backbone of any soap production line: the mixer, the plodder, and the cutter.

1. The Heart of Homogeneity: The Soap Noodles Mixer

The journey begins with blending raw soap noodles (base material) with fragrances, colors, active ingredients, and other additives. This is where a high-performance soap mixer proves indispensable. A quality mixing machine ensures uniform distribution of all components throughout the soap mass. Inconsistent mixing leads to variations in scent, color, texture, and efficacy – flaws unacceptable in the market. Modern soap noodles mixers are designed for thoroughness and speed, handling batches efficiently while maintaining the integrity of sensitive ingredients. Investing in a reliable mixer is the first step towards achieving a superior, uniform product base ready for forming. For businesses seeking tailored solutions, custom soap cutting machine expertise can often extend to mixer design as well.

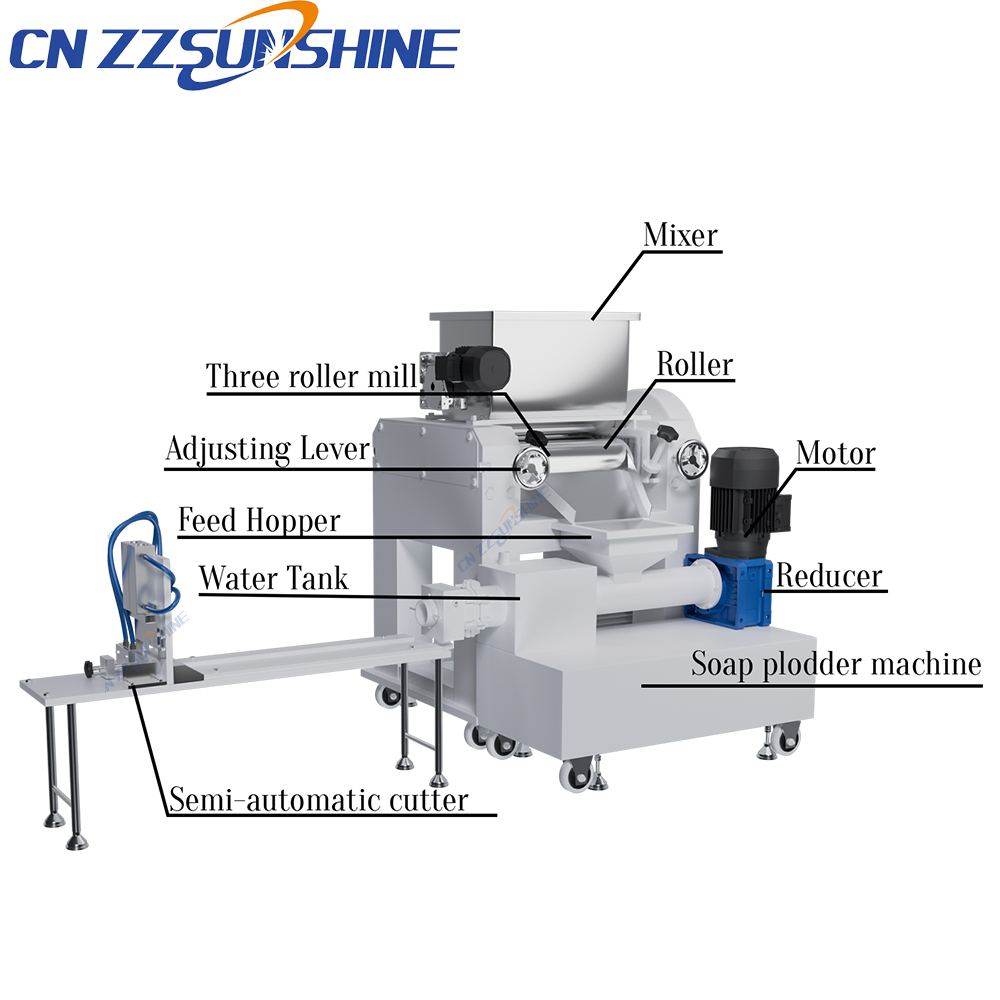

2. Forming the Bar: The Crucial Role of the Soap Plodder

Once perfectly mixed, the soap mass needs to be transformed into a continuous, dense bar. Enter the soap plodder machine for bar soap, often a vacuum plodder. This machine compresses the soap mixture under vacuum conditions, expelling trapped air and moisture. This vacuum plodder process is vital. It significantly increases the soap’s density, resulting in a harder, longer-lasting bar with a smoother texture and better lathering properties. The plodder extrudes the compacted soap through a die, forming a continuous log of the desired shape and size (e.g., oval, rectangular). The quality of extrusion directly impacts the final bar’s appearance and structural integrity. Whether part of a laundry soap making line or a toilet soap finishing line, the soap plodder is non-negotiable for premium bar production.

3. Precision Cutting: Achieving Perfect Bar Dimensions

The continuous soap log exiting the plodder must be cut into individual bars of precise weight and dimension. This is the domain of the soap cutter cutting machine. Precision cutting is critical for branding consistency, packaging efficiency, and meeting consumer expectations. Modern solutions often involve an automatic block cutter machine, which uses advanced mechanisms (like electronic cutting machine or pneumatic cutting machine systems) to slice the log with exceptional accuracy and minimal waste. While manual cutting machine options exist for very small-scale or artisanal production (mini soap production line), automated cutters are essential for any serious automatic soap production line aiming for volume and consistency. An electric washing soap cutter might be specified for specific wash-down environments.

Integrating for Success: The Complete Soap Making Production Line

While the mixer, plodder, and cutter form the core trio, a complete soap making production line integrates seamlessly with other vital equipment. This includes oem three roller grinding mill for refining base materials (if producing noodles in-house), soap stamping machine for branding, film packaging machine for wrapping, and potentially washing liquid production equipment for diversification. Automatic printers or semi-automatic printers handle batch coding and labeling. Choosing machines that integrate well, from the soap mixer through to the soap cutter, ensures smooth material flow and minimizes bottlenecks.

Conclusion: Quality Machinery, Quality Results

Investing in a professional production line soap making machine, a reliable soap noodles mixer, and a high quality soap cutter cutting machine is an investment in your brand’s reputation and bottom line. These machines guarantee the consistent quality consumers demand, enable efficient high-volume production for profitability, and minimize waste through precision operation. Whether establishing a laundry bar soap production line, a beauty soap making line, or a bath soap making machine setup, prioritizing these core pieces of equipment ensures you deliver a superior product efficiently. Finding the best price is important, but never at the expense of the reliability and quality these essential machines provide.