Unlocking Efficiency in Soap Manufacturing: The Power of Integrated Machinery

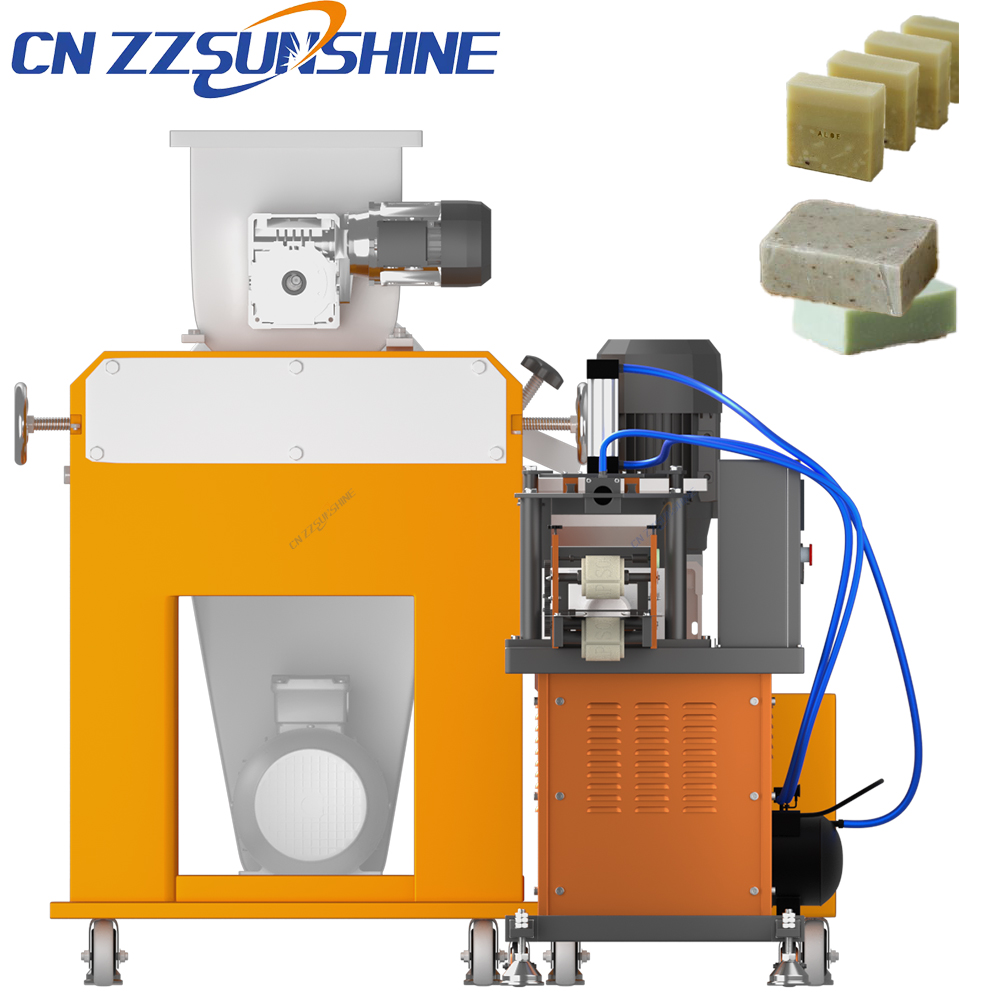

For soap manufacturers aiming to scale operations, enhance product quality, and maintain competitive pricing, investing in the right machinery is paramount. Moving beyond standalone units to integrated solutions like a Professional Complete Set Chemical Soap Making Machine offers significant advantages. This article explores how modern equipment, including high-performance soap plodder machines for bar soap and precise automatic block cutter machines, streamlines production from start to finish.

The Foundation: Comprehensive Production Lines

Whether targeting the laundry soap market with a dedicated laundry bar soap production line or producing premium toiletries via a toilet soap finishing line, the efficiency of an Automatic soap production line cannot be overstated. These integrated systems typically incorporate robust soap mixers (or Mixing machines) for consistent blending of raw materials and Vacuum plodders essential for extruding high-density, homogenous soap noodles free of air pockets. This initial stage is critical for ensuring the final bar’s structural integrity and longevity. For smaller ventures or specialized products, a Mini Soap Production Line provides a cost-effective entry point without sacrificing core functionality. The integration of Film Packaging Machines and Soap Stamping Machines further automates the finishing stages, ensuring a polished, market-ready product.

Precision Cutting: Enhancing Quality and Consistency

A key component within any soap making production line is the cutting phase. Here, the choice between a Manual Cutting Machine, an Electronic Cutting Machine, or a Pneumatic Cutting Machine depends largely on volume and precision requirements. However, for manufacturers prioritizing consistent bar dimensions and high output, investing in an automatic block cutter machine is often the optimal solution. These machines, sometimes referred to as Electric washing soap cutters, deliver unparalleled accuracy. They seamlessly integrate with extruders, automatically cutting extruded soap logs into uniform blocks or bars with minimal waste. This precision directly translates to a superior final product and reduced material costs. When seeking a Quality Soap Cutter Cutting Machine, focus on features like adjustable cutting lengths, blade durability, and ease of integration within your existing line.

Customization and Flexibility: Meeting Diverse Needs

No two soap manufacturing operations are identical. Recognizing this, leading equipment suppliers offer extensive customization options. A custom soap cutting machine can be engineered to handle specific bar sizes, shapes (like oval bath bars), or even harder specialty soaps. Beyond cutters, OEM three roller grinding mills are vital for refining soap pastes in certain processes, particularly for high-end beauty soap making lines. The flexibility extends to ancillary equipment like Semi-automatic Printers or Automatic Printers for branding. The concept of a Complete Soap Making Machine Low Price doesn’t imply sacrificing quality; rather, it represents sourcing well-engineered, reliable equipment configured precisely to your operational needs, maximizing return on investment.

Conclusion

Optimizing soap production hinges on selecting machinery that offers reliability, precision, and scalability. From the foundational work of the soap plodder and mixer to the critical finishing stages achieved by automated cutters and stampers, each component within a Professional Complete Set Chemical Soap Making Machine plays a vital role. By carefully evaluating your production requirements – be it for a dedicated bath soap making machine line or a versatile setup handling multiple product types – and partnering with suppliers offering customization (OEM) and robust solutions, manufacturers can significantly boost efficiency, ensure consistent quality, and maintain competitiveness in the dynamic soap market. Explore tailored soap making machine solutions today to elevate your production capabilities.