The Power Behind the Press: Why Pneumatic Soap Stampers Are Essential for Quality Bar Soap

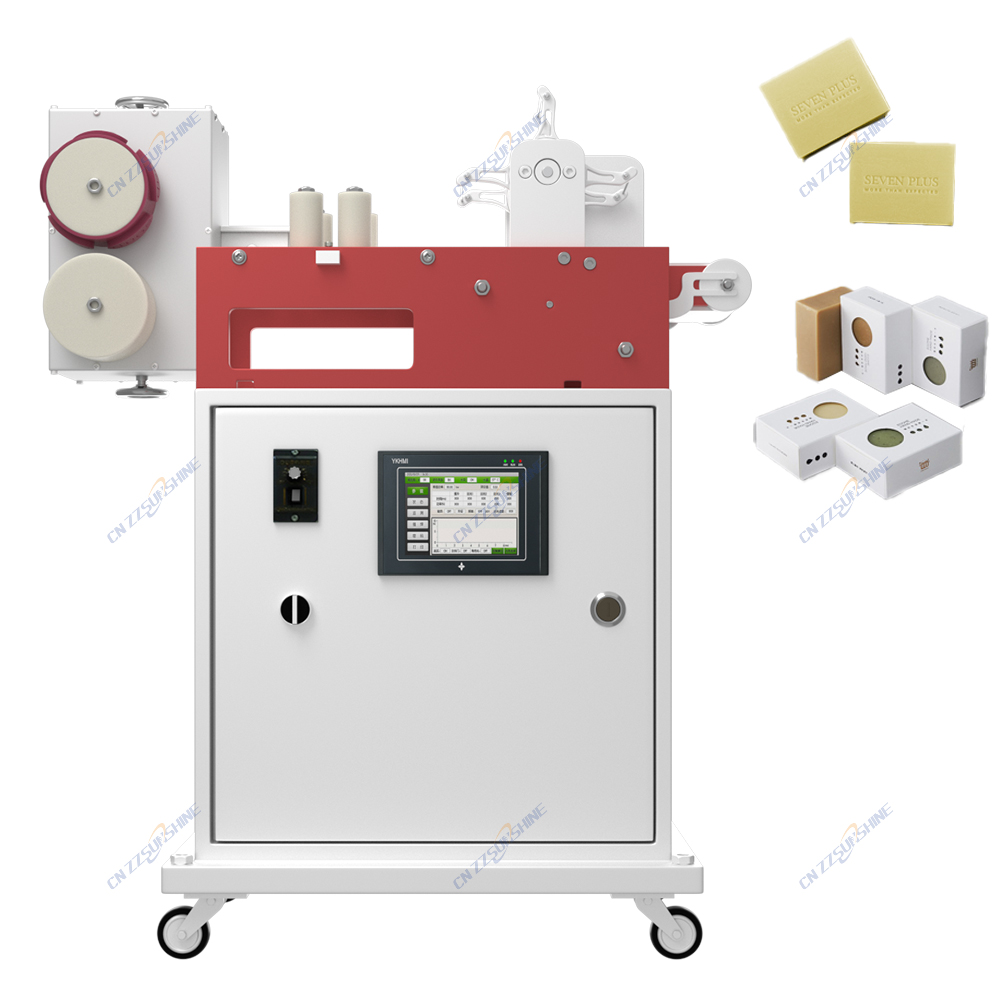

In the intricate dance of bar soap production, achieving that perfect, professional finish isn’t just about aesthetics – it’s a hallmark of quality and brand identity. This is where the soap stamping machine plays a pivotal role. While various stamping methods exist, the pneumatic soap stamper stands out as a robust and efficient solution, particularly valued in toilet soap finishing lines and laundry bar soap production lines.

But what exactly makes a pneumatic stamper tick? Unlike purely manual or hydraulic alternatives, pneumatic stampers utilize compressed air to drive the stamping mechanism. This offers several distinct advantages. Firstly, it delivers consistent, powerful pressure with each stroke, ensuring crisp, clear logos and designs are imprinted onto every bar, regardless of size or hardness. This repeatability is crucial for maintaining brand standards across high-volume outputs.

Secondly, pneumatic systems are known for their speed and responsiveness. Compressed air allows for rapid cycling of the stamping head, significantly increasing production rates compared to slower manual methods. This efficiency makes them ideal for medium-scale operations looking to boost throughput without compromising on finish quality. Furthermore, pneumatic systems are generally durable and require less complex maintenance than hydraulic counterparts, contributing to lower long-term operating costs.

Integrating a pneumatic soap stamper effectively often depends on the preceding stages of your soap making production line. It typically follows equipment like the soap plodder machine for bar soap, which extrudes and compresses the soap mass, and the automatic block cutter machine or pneumatic cutting machine that slices the continuous log into individual bar blanks. The precision of these cutting machines ensures bars are uniform in size and weight, providing a consistent base for the stamper to work its magic. After stamping, bars usually proceed to cooling, drying, and potentially wrapping via a film packaging machine.

For businesses operating a mini soap production line or a semi-automatic printer setup, a pneumatic stamper offers a sweet spot between manual effort and full automation. It provides the force and consistency needed for professional results without the complexity and investment of a fully automatic soap production line. Whether you’re producing delicate beauty bars on a beauty soap making line or robust laundry soap, the reliable pressure and speed of a pneumatic soap stamping machine ensure your final product looks as good as it functions. It’s a smart investment in both efficiency and brand presentation.