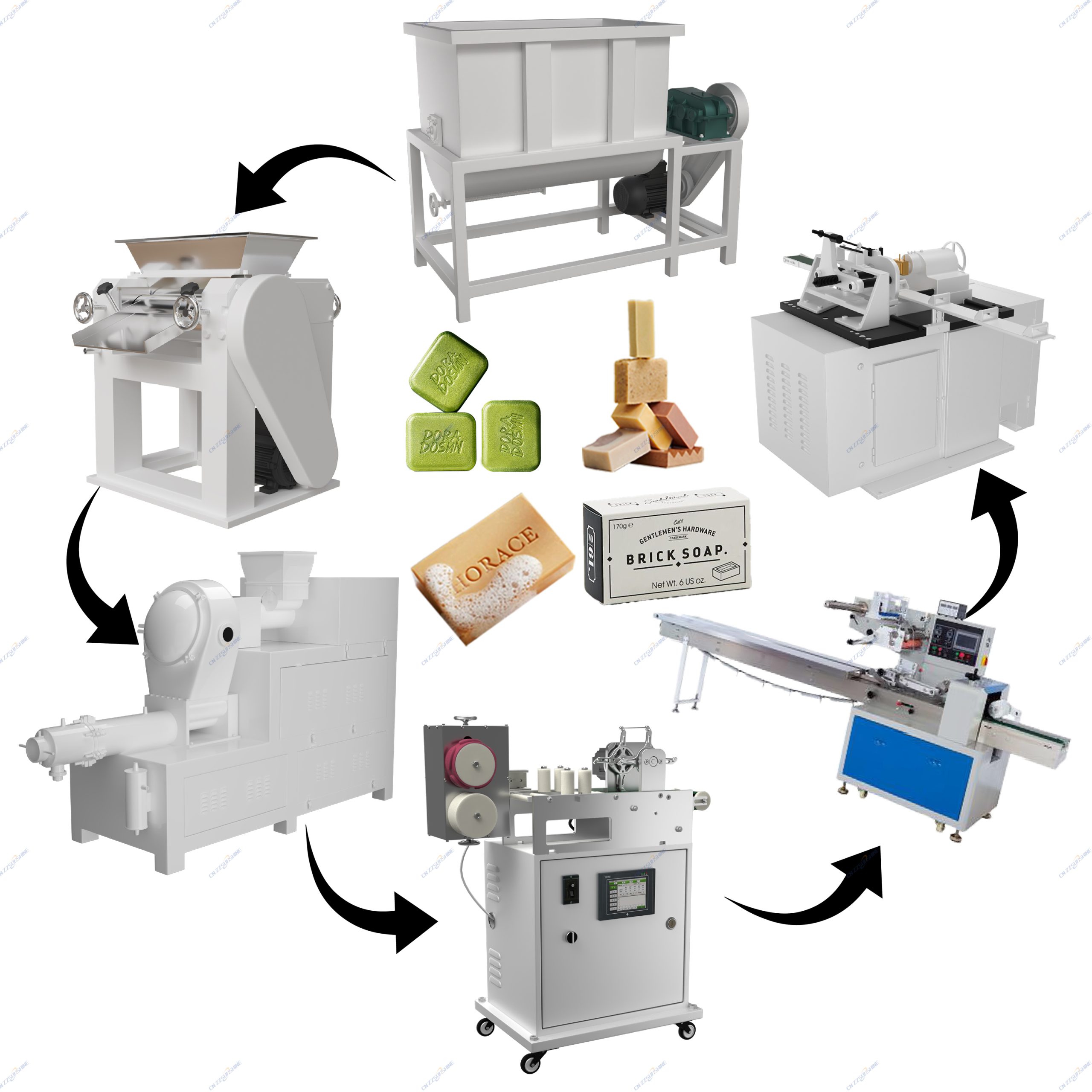

Streamlining commercial soap manufacturing demands precision, consistency, and efficiency. Implementing a fully integrated automatic soap production line is the definitive solution for businesses aiming to scale output while maintaining superior quality control, whether targeting the laundry bar soap production line market or premium toilet soap finishing lines. These sophisticated systems eliminate manual bottlenecks inherent in batch processing.

The core of a high-performance line begins with robust mixing. An industrial mixer for chemical processing ensures homogeneous blending of fats, oils, lye, and additives under controlled conditions, critical for consistent saponification and final bar properties. This mixed soap base then moves to the refining stage. A high-shear three roller mill for cosmetics processing is often employed, especially in beauty soap making lines, to achieve an exceptionally smooth texture and uniform dispersion of pigments or exfoliants. For traditional bar soaps, refining typically occurs within the plodder itself.

The plodder, specifically a vacuum plodder machine, is the heart of the line. It compacts the soap noodles, removes trapped air (preventing bubbles and ensuring bar density), and continuously extrudes a solid, uniform log of soap. Modern vacuum plodders offer precise control over extrusion pressure and vacuum levels. This extruded log is then conveyed to cutting.

Precision cutting is paramount for product appearance and minimizing waste. An automatic block cutter machine, often an electric washing soap cutter, utilizes servo-driven blades or high-pressure water jets to slice the log into individual billets with exact dimensions. For specialized shapes or custom soap cutting machine requirements, downstream units can be integrated. Finally, the cut billets proceed to stamping, cooling (potentially using an industrial chiller for machinery cooling), and automated packing.

The advantages of a complete automatic soap production line are compelling: significantly increased throughput, reduced labor costs, minimized material waste, enhanced worker safety by handling caustic materials in closed systems, and guaranteed product uniformity batch after batch. Leading china feed processing machine suppliers often diversify into soap machinery, offering both standard bath soap making machines and custom-engineered laundry soap making line solutions. Investing in an automated line, featuring a reliable soap plodder and integrated cutter, delivers a rapid return on investment through operational excellence and market responsiveness.