The modern soap market demands efficiency, consistency, and stringent hygiene standards. For manufacturers aiming to scale production and enhance product quality, transitioning from manual or semi-automated processes to a fully integrated **automatic soap production line** is no longer a luxury, but a competitive necessity. These sophisticated lines streamline the entire journey from raw materials to finished bars, significantly boosting output while reducing labor costs and waste.

At the heart of any high-volume **laundry bar soap production line** or **toilet soap finishing line** lies the **soap mixer** or **mixing machine**. This critical component ensures uniform blending of fats, oils, alkalis, fragrances, and additives, creating a homogeneous base. The mixed soap mass then moves to the refining stage, often involving specialized mills like an **OEM three roller grinding mill** for cosmetics-grade soaps requiring ultra-fine texture, crucial for **beauty soap making line** operations.

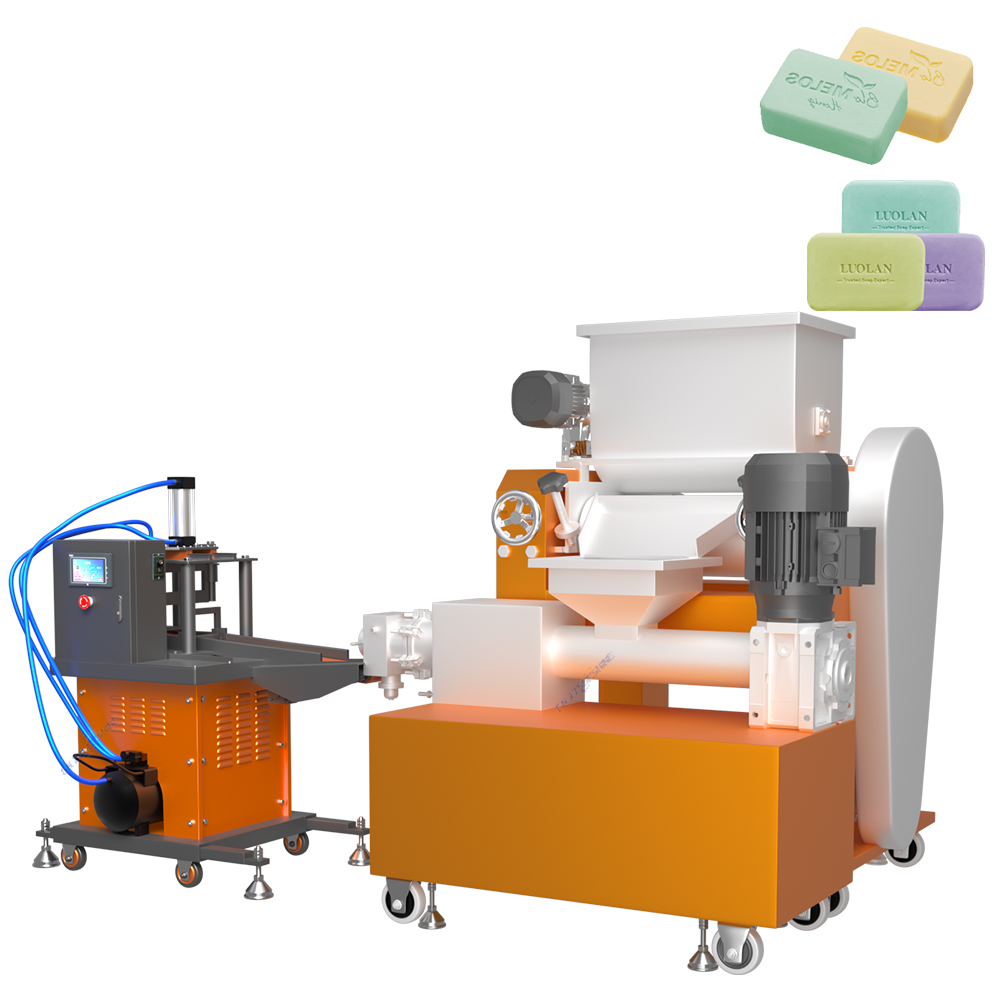

Refined soap next enters the **vacuum plodder** or **soap plodder machine**. This stage is vital for de-aeration and forming a dense, consistent log. High-quality **soap plodder** units remove trapped air under vacuum, preventing bubbles and ensuring a smooth, hard bar that won’t crumble. The extruded log is then precisely cut to size. Modern lines utilize highly accurate **custom soap cutting machines** or **electric washing soap cutters**, capable of rapid, uniform slicing with minimal waste, adjustable for various bar dimensions needed in **laundry soap making lines** or **bath soap making machines**.

Finally, the cut bars proceed to stamping, cooling, and often, automated wrapping. Integrating an **automatic packing machine for food**-grade standards ensures hygienic, efficient packaging suitable for both industrial **laundry soap** and consumer **toilet soap**.

The advantages of a complete **soap making production line** are clear: dramatically increased throughput, superior product uniformity, enhanced hygiene control, and reduced operational expenses. When selecting equipment, partnering with experienced manufacturers who understand the nuances of **soap making machine** integration—from the **soap mixer** and **vacuum plodder** to the precision **cutter**—is paramount for achieving optimal return on investment and maintaining a competitive edge in the demanding global soap market.