Streamlining bar soap manufacturing demands precision, efficiency, and consistent quality. Modern automatic soap production lines integrate specialized machinery to transform raw materials into finished bars with minimal manual intervention, maximizing output and profitability. This integrated approach is essential for competitive manufacturers targeting laundry bar soap production lines, toilet soap finishing lines, or bath soap making machines.

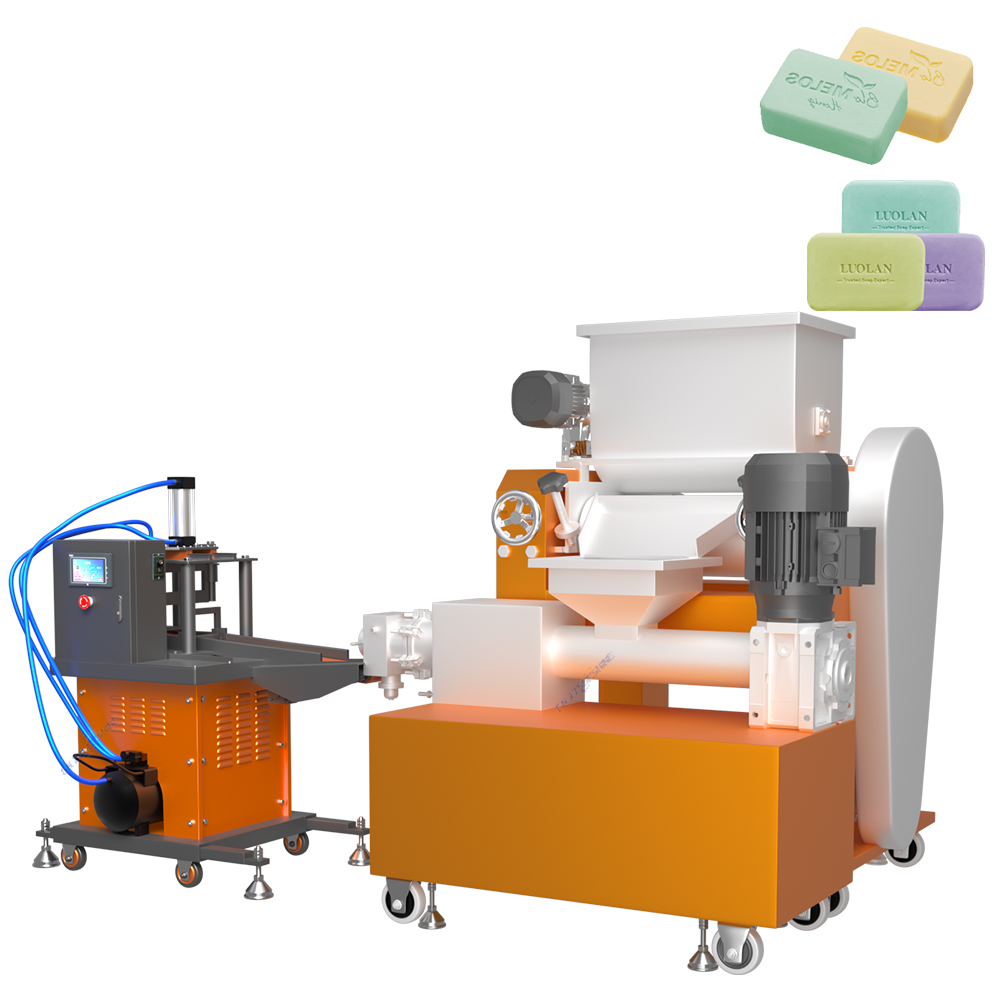

The process begins with thorough ingredient preparation. A robust industrial mixer for chemical processing blends fats, oils, alkali, and additives into a homogeneous soap base. Consistent mixing is non-negotiable for product integrity. This mixture then moves to refining stages, where a vacuum plodder becomes critical. This specialized soap plodder machine for bar soap removes air pockets under controlled vacuum pressure, ensuring a dense, smooth texture while enhancing lather quality and bar durability. The vacuum environment prevents oxidation, preserving the soap’s properties.

Following extrusion from the vacuum plodder, the continuous soap log requires precise sizing. An electric washing soap cutter delivers this accuracy, cleanly slicing logs into uniform billets or bars with adjustable speed and cutting dimensions. For high-volume facilities or specialized shapes, a custom soap cutting machine offers tailored solutions. The final stages involve finishing and packaging. A dedicated toilet soap finishing line might include stamping, polishing, and inspection stations, while laundry soap making lines focus on rapid curing and bundling. An automatic packing machine for food-grade standards ensures hygienic, efficient wrapping for retail or bulk distribution.

The advantages of a fully integrated system are clear: reduced labor costs, minimized human error, consistent product quality, and scalable throughput. Key components like the vacuum plodder, industrial mixer, and electric washing soap cutter work synergistically under automated controls. For manufacturers seeking to upgrade or establish new capacity, investing in a cohesive automatic soap production line, incorporating a reliable soap plodder and precise cutter, represents a strategic move towards dominating the competitive bar soap market.