Modern soap manufacturing demands efficiency, consistency, and scalability. Implementing a fully integrated **automatic soap production line** is the definitive solution for factories aiming to boost output and quality while controlling costs. This sophisticated system seamlessly links essential components, transforming raw materials into finished bars with minimal manual intervention.

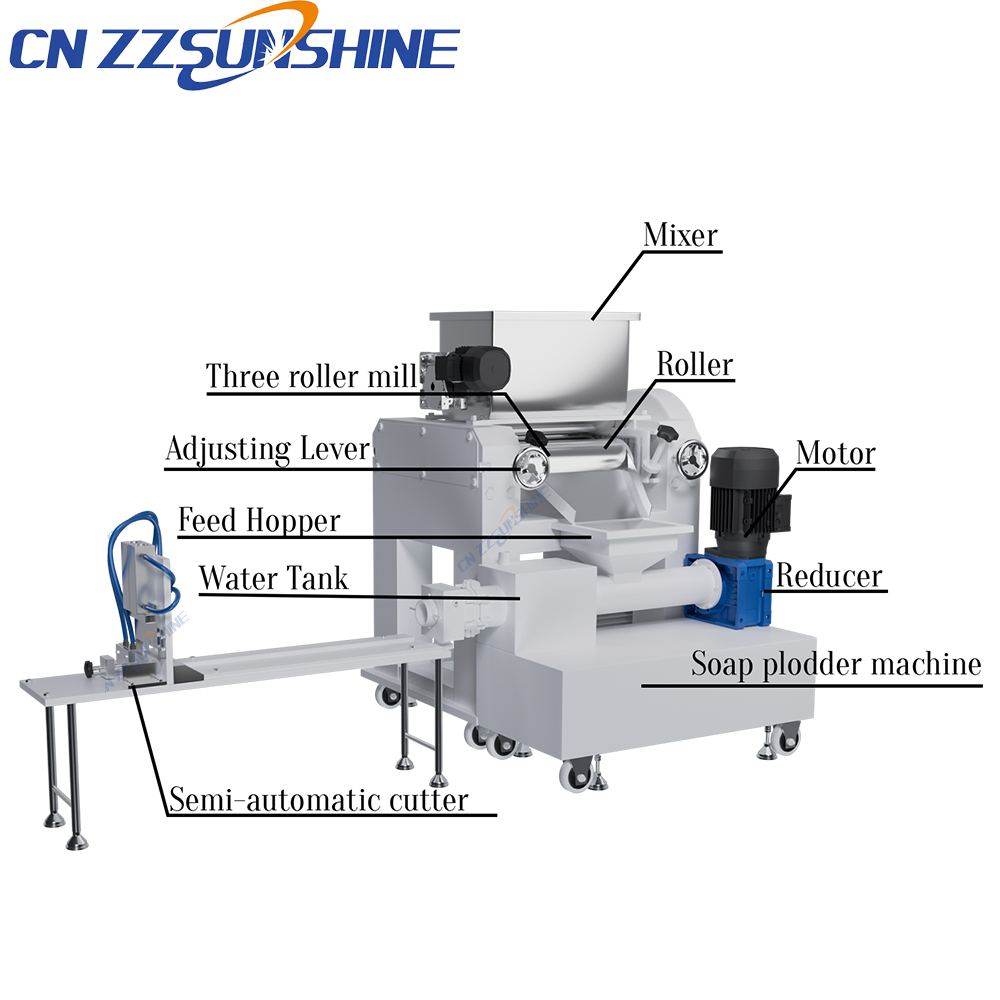

The process begins with precision ingredient handling. An industrial **soap mixer**, specifically engineered for **chemical processing**, ensures homogeneous blending of fats, alkalis, additives, and fragrances under controlled conditions. This critical step guarantees batch-to-batch uniformity. The mixed soap base then undergoes refining and de-aeration in a **vacuum plodder**. This machine is the heart of many **toilet soap finishing lines** and **laundry bar soap production lines**, working under vacuum to remove air pockets, creating a denser, smoother bar that lathers better and lasts longer. The vacuum plodder extrudes a continuous, solid log of soap.

This log proceeds to the shaping and cutting stage. A high-speed **soap cutting machine**, often an **electric washing soap cutter** or **automatic block cutter machine**, precisely sections the log into individual billets or bars. Modern **custom soap cutting machines** offer adjustable settings for various bar sizes and shapes, essential for diverse product lines like **beauty soap making lines**. For intricate designs, a **three roller mill for cosmetics** principles can sometimes be incorporated earlier for ultra-fine milling of additives.

Finally, the cut bars move through optional finishing stages (stamping, cooling, polishing) before **automatic packing**. Integrating an **automatic packing machine for food-grade** standards ensures hygienic, efficient wrapping suitable for both **laundry soap making lines** and premium **toilet soap finishing lines**.

The advantages of a cohesive **soap making production line** are compelling. It drastically reduces labor costs, minimizes human contact with the product (enhancing hygiene), ensures unparalleled consistency in weight, size, and density, and significantly increases production capacity. Whether you’re establishing a new **bath soap making machine** setup or upgrading an existing **soap plodder machine for bar soap** operation, investing in an integrated, **automatic soap production line** delivers a rapid return on investment through superior efficiency and product quality. Partnering with experienced OEM manufacturers ensures the line is optimized for your specific throughput and product requirements.