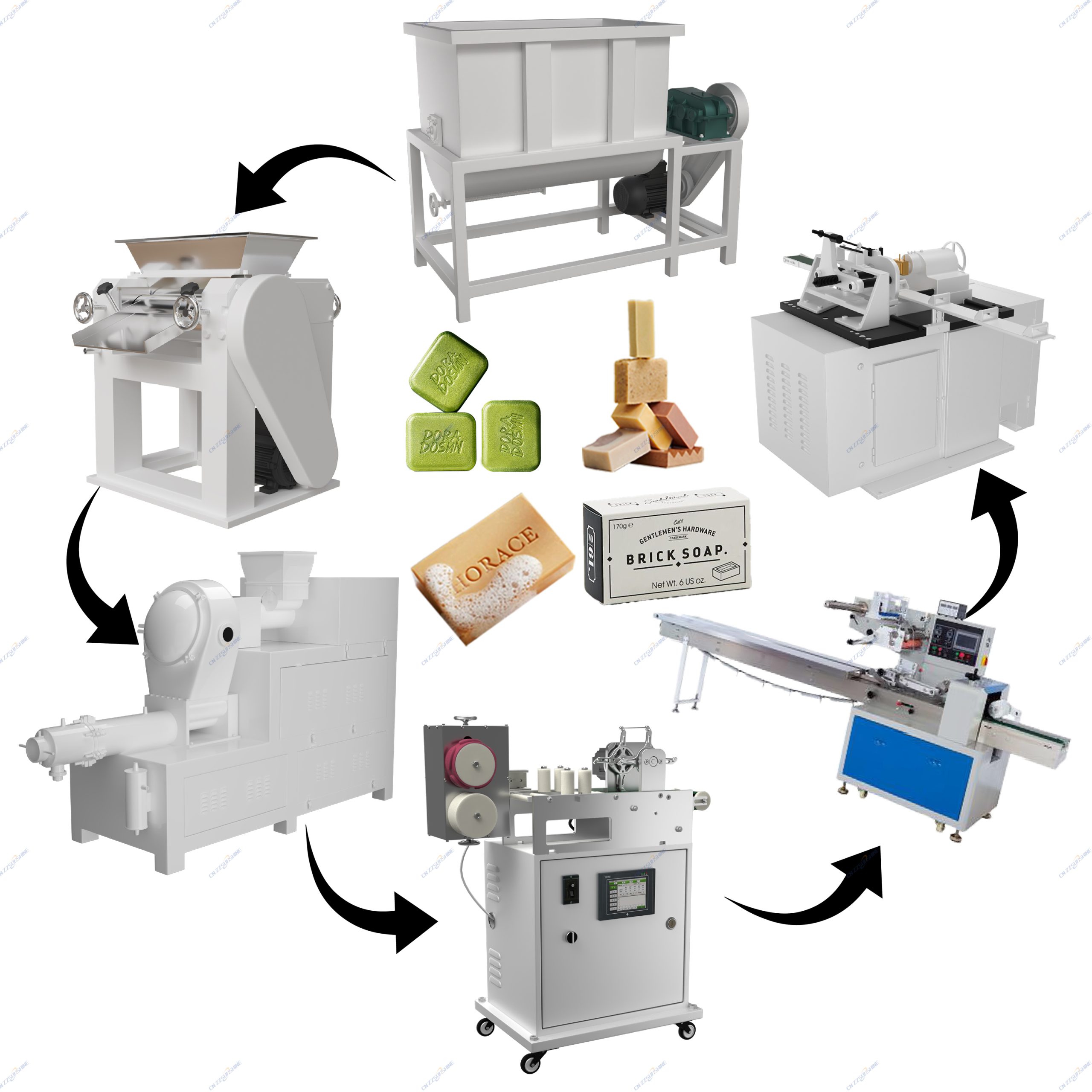

Building a reliable and profitable soap making production line hinges on selecting the right core machinery. Whether you’re focused on laundry bar soap production line setups, a dedicated toilet soap finishing line, or a versatile bath soap making machine, understanding the function of each component is crucial for quality and efficiency.

The process truly begins with thorough mixing. An industrial mixer for chemical processing is essential for combining fats, oils, lye, and additives into a homogeneous soap base. Consistent mixing is non-negotiable for uniform saponification and final product quality. From there, the mixed soap mass moves to refining and extrusion. This is where a soap plodder machine for bar soap becomes indispensable. Modern vacuum plodder units are particularly effective. By operating under vacuum (typically 15-20 bar), they meticulously remove air bubbles during extrusion, resulting in a denser, smoother bar that lathers better and lasts longer. This step significantly elevates the quality of both laundry soap making line outputs and premium toilet soaps.

Once extruded into continuous logs, precision cutting is paramount. An electric washing soap cutter or a custom soap cutting machine provides the accuracy needed for consistent bar weight and size, minimizing waste. Customization here is key, allowing producers to easily switch between different bar dimensions for various product lines – be it a laundry bar soap production line or a beauty soap making line – without costly downtime.

Integrating these components – the robust industrial mixer, the efficient vacuum plodder, and the precise cutter – into a cohesive automatic soap production line is the ultimate goal for scaling manufacturers. Automation streamlines operations, reduces labor costs, enhances consistency, and boosts overall output. While the initial investment in a high-quality soap plodder, advanced soap mixer, and automated cutting system is significant, the long-term gains in product quality, reduced waste (often 5-10% higher yield versus manual lines), and operational efficiency make it essential for competitive soap production. Partnering with experienced manufacturers who understand the nuances of integrating a vacuum plodder effectively or tailoring a custom soap cutting machine ensures your line operates at peak performance from day one.