Implementing an efficient soap making production line is crucial for manufacturers targeting consistent quality and high output. The process begins with precise material handling. An industrial mixer for chemical processing ensures uniform blending of fats, oils, lye, and additives, creating a homogeneous base soap. This stage is critical; improper mixing leads to defects later.

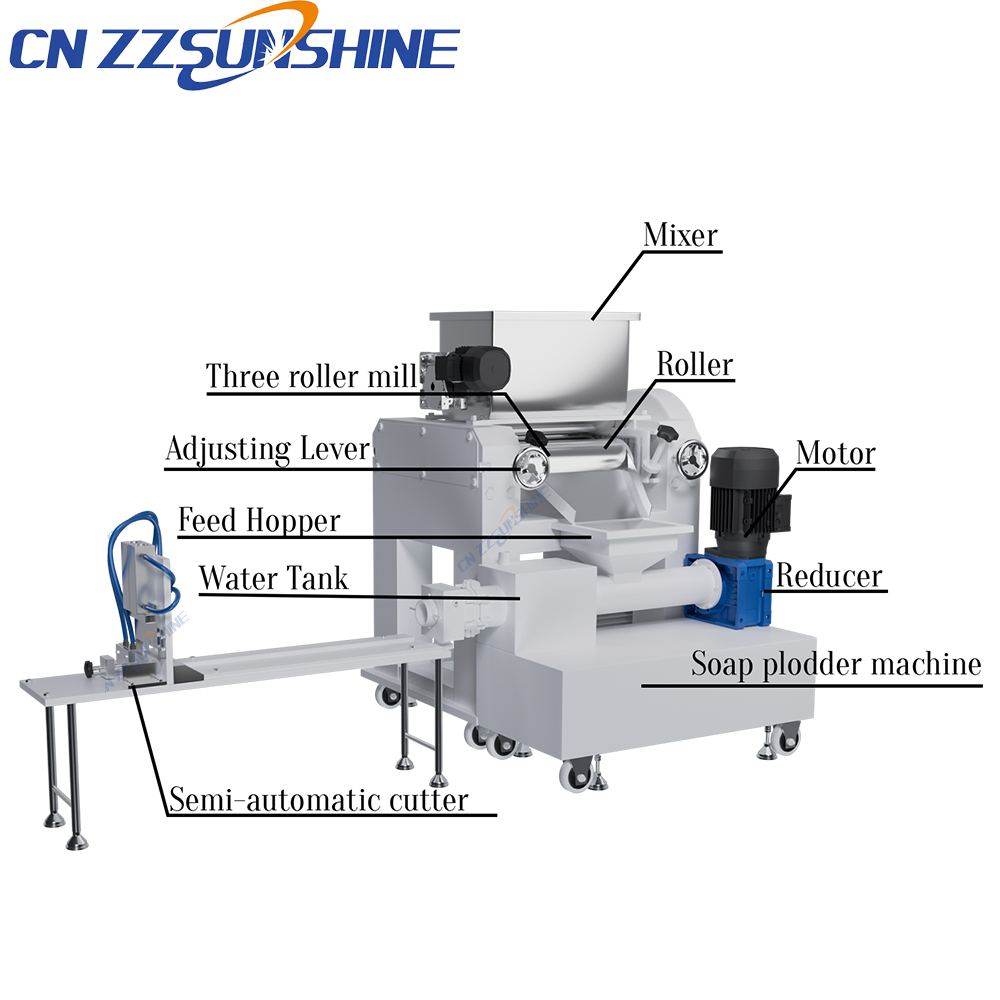

The mixed soap then moves to the core refining stage. Utilizing a vacuum plodder is essential. This specialized soap plodder machine for bar soap performs two vital functions: it extrudes the soap through a die under pressure to form a continuous log, and critically, it operates under vacuum to remove air pockets. This vacuum deaeration significantly enhances the final bar’s density, lather quality, and longevity, preventing crumbling. For premium toilet soap or translucent beauty bars, a three roller mill for cosmetics (or often a triple configuration) is frequently integrated either before or after the plodder. This roller mill refines the soap’s texture, ensuring unparalleled smoothness and homogenization.

Following extrusion, the continuous soap log requires precise sizing. An electric washing soap cutter offers high accuracy and hygiene, slicing the log into individual bar-sized pieces with minimal waste. For diverse bar shapes or weights, a custom soap cutting machine provides the necessary flexibility. Finally, the bars proceed through the finishing stages of the toilet soap finishing line or laundry bar soap production line, involving stamping, cooling, quality checks, and packaging. Integrating an automatic soap production line, potentially including an automatic packing machine for food-grade packaging, maximizes throughput and minimizes labor costs.

Investing in a well-integrated laundry soap making line or bath soap making machine system, focusing on key components like the high-shear soap mixer, efficient vacuum plodder, and precise cutter, directly impacts product quality, production efficiency, and overall profitability. Choosing reliable technology partners, potentially including a China feed processing machine supplier with diversified expertise, ensures access to robust machinery like the soap plodder and mixing machine designed for demanding industrial cycles.