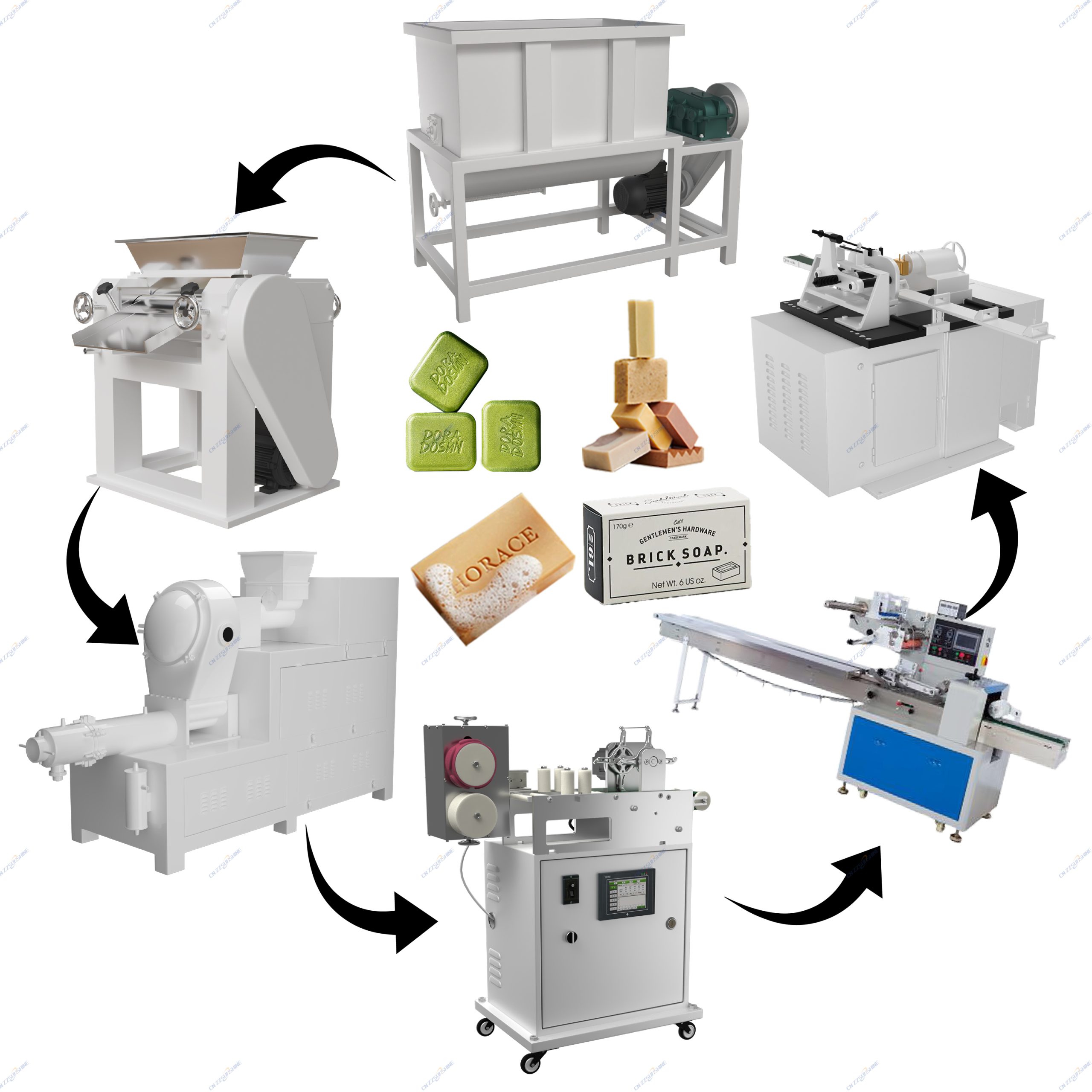

Efficient soap manufacturing hinges on integrated equipment that handles every phase without bottlenecks. Modern soap making production lines start with high-shear mixing machines that ensure homogeneous blending of fats, lye, and additives. For bar soap operations, a robust soap plodder machine for bar soap is non-negotiable—it compresses mixed soap into a dense, bubble-free log. Vacuum plodder variants excel here by eliminating air pockets, enhancing product integrity.

Downstream, precision cutting defines soap bar consistency. An electric washing soap cutter offers adjustable slicing widths for laundry bars, while custom soap cutting machine configurations accommodate unique shapes for boutique bath soap making machines. For large-scale laundry bar soap production lines, automated conveyors feed logs into dual-speed cutters, minimizing waste.

Finishing stages vary: laundry soap making lines prioritize rapid curing and stamping, whereas toilet soap finishing lines integrate polishing, stamping, and wrappers for consumer appeal. Automation shines in end-stage packaging—we recommend integrated automatic packing machines for food-grade standards, adaptable for soap blocks.

Critical considerations? First, match your soap mixer capacity to plodder throughput to prevent underutilization. Second, opt for modular designs allowing easy upgrades—like adding a vacuum plodder to existing setups. Third, prioritize stainless-steel contact surfaces for hygiene compliance in bath soap or beauty soap making lines.

Leading suppliers now offer turnkey automatic soap production line solutions with PLC controls, reducing labor costs by 40%. For niche producers, OEM three roller grinding mills can refine additives pre-mixing. Remember: A synchronized laundry soap making line operating at 90% efficiency outperforms fragmented setups at 100% capacity. Invest in unified controls and predictive maintenance—your ROI hinges on seamless transitions between mixing, plodding, and cutting phases.