Running a profitable soap manufacturing operation hinges on the efficiency and reliability of your core equipment. A well-integrated **soap making production line** is fundamental, transforming raw materials into finished bars consistently and cost-effectively. This involves several critical stages, each demanding specialized machinery.

The process begins with precise ingredient handling. A robust **industrial mixer for chemical processing** ensures fats, oils, lye, and additives are blended uniformly under controlled conditions, forming the foundational soap base (saponified paste). Consistent mixing is paramount for quality. Following this, the paste undergoes refining and homogenization. While **three roller mills for cosmetics** excel in fine cosmetic applications, soap production often utilizes dedicated refining units within the line to achieve the desired texture and remove impurities before plodding.

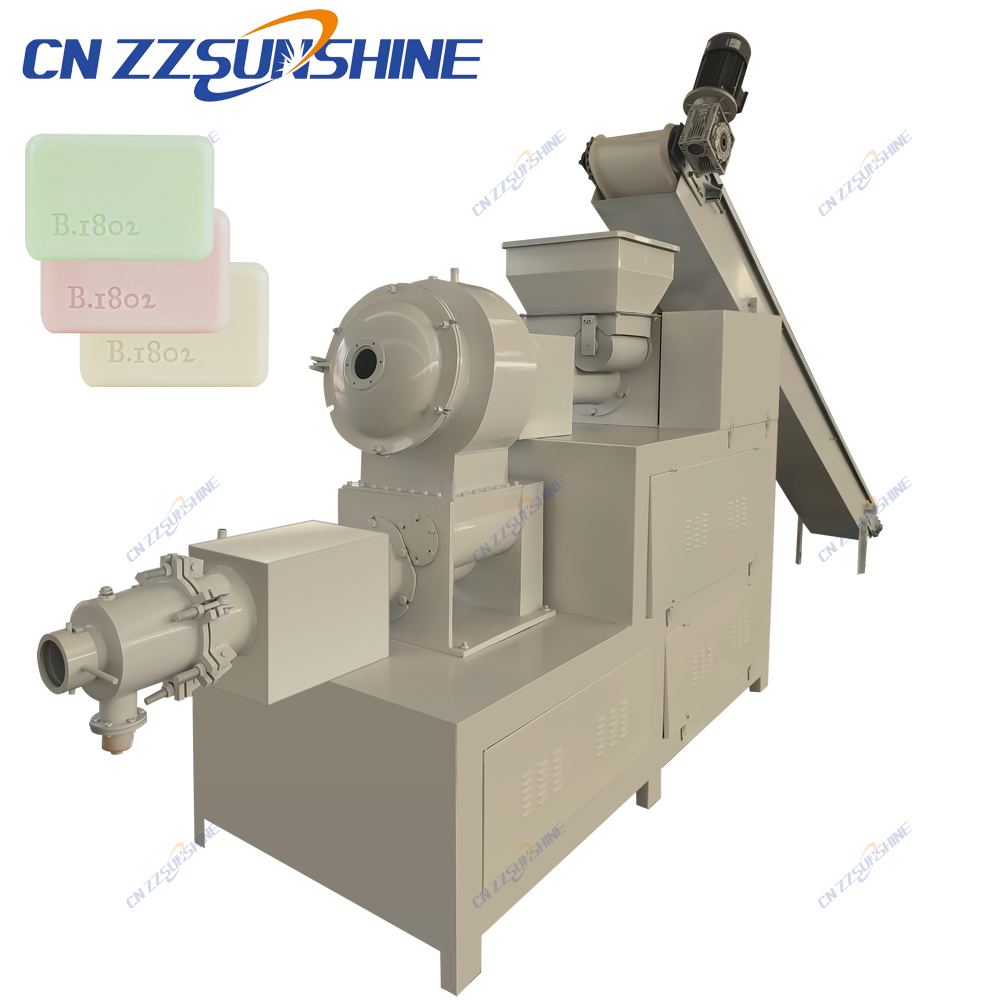

The heart of solid bar formation lies in the **plodder machine for bar soap**. Modern lines frequently employ a **vacuum plodder**, which removes air pockets under vacuum pressure. This crucial step compacts the soap mass, significantly enhancing bar density, durability, and lathering properties, resulting in a superior final product. The compacted soap log then exits the **soap plodder** continuously.

Next comes shaping and cutting. An **automatic soap cutter machine** slices the extruded log into precise blanks with minimal waste. For high-volume operations like **laundry bar soap production lines** or **toilet soap finishing lines**, **electric washing soap cutters** offer speed and precision. Depending on the product type (laundry soap, bath soap, beauty soap), the blanks may proceed directly to stamping or undergo additional finishing steps like milling, extruding again, or stamping/polishing within a dedicated **bath soap making machine** or **beauty soap making line** section.

Finally, efficient packaging is essential. Integrating an **automatic packing machine for food**-grade applications ensures hygienic wrapping of the finished bars, ready for distribution. The true power lies in the seamless integration of these components – the **soap mixer**, **vacuum plodder**, and **automatic soap cutter** – into a cohesive **automatic soap production line**. This integrated approach minimizes manual handling, boosts throughput, ensures consistent quality, and maximizes ROI. Choosing the right configuration, whether for a robust **laundry soap making line** or a sophisticated **toilet soap finishing line**, tailored to your specific output targets and product specifications is key to dominating the market.