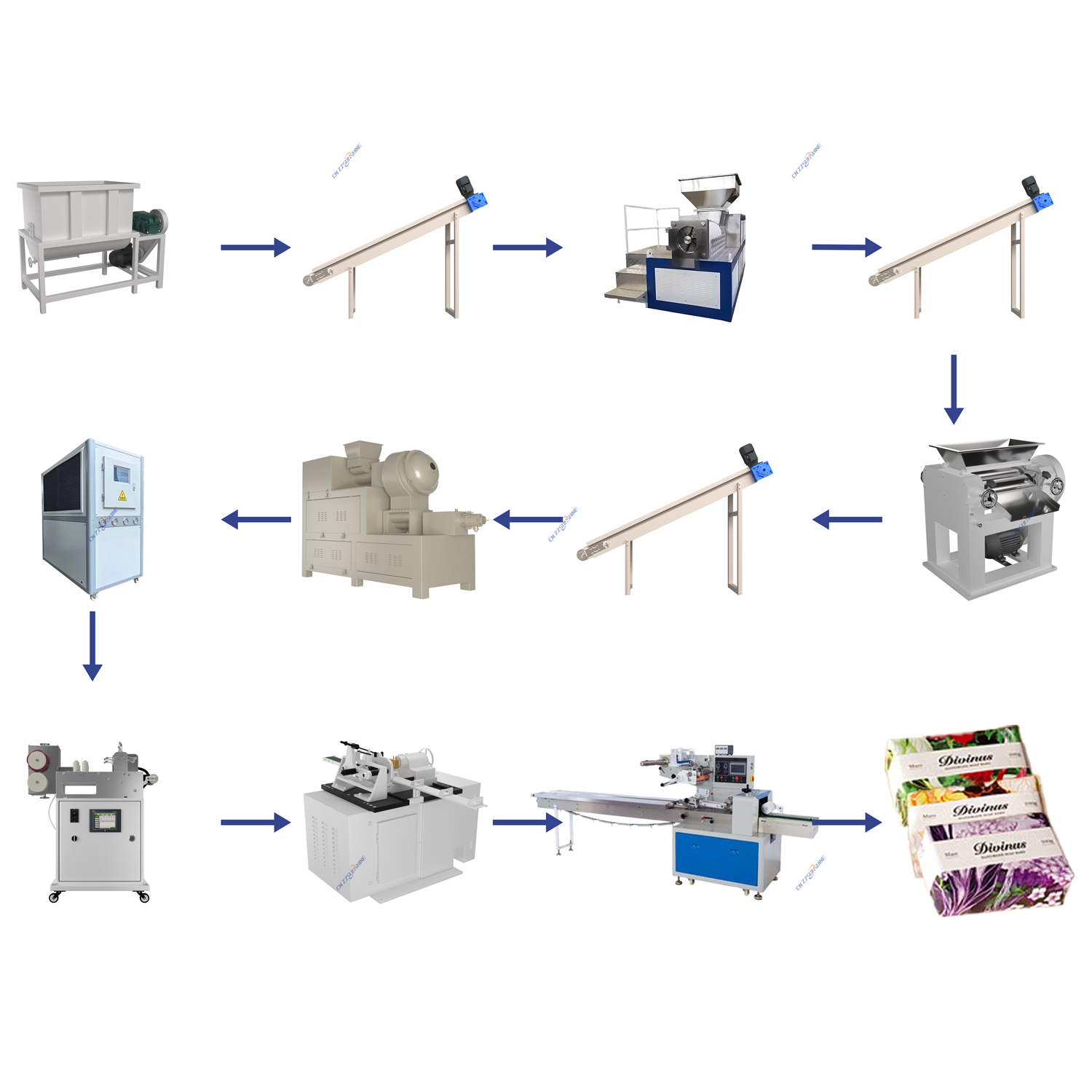

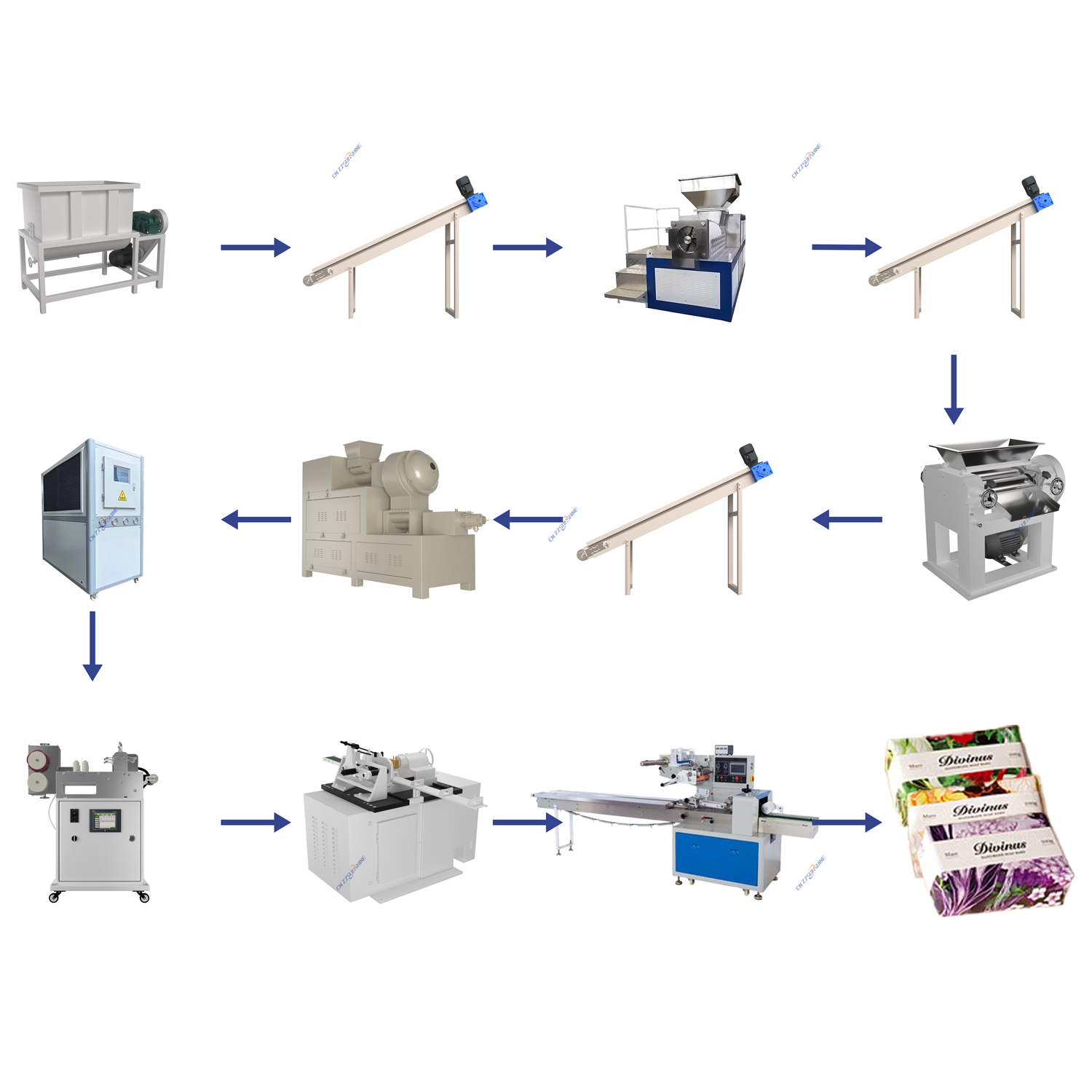

Building a competitive bar soap operation requires precision machinery. A well-designed soap making production line integrates several key components to ensure consistent output, whether for laundry bar soap production lines or premium toilet soap finishing lines. At the heart lies the soap mixer, crucial for homogenizing fats, alkalis, and additives. Industrial mixers for chemical processing must handle varying viscosities safely. The mixed soap base then moves to the vacuum plodder. This critical soap plodder machine for bar soap removes air pockets under vacuum, significantly enhancing the final bar’s density, lather, and longevity – essential for bath soap making machine quality. Following extrusion, the soap log requires precise cutting. While manual cutters exist, an electric washing soap cutter or custom soap cutting machine delivers uniform bar sizes and weights, minimizing waste. For high-volume operations, an automatic soap production line integrates these stages seamlessly, often including automatic cooling tunnels using a factory price industrial chiller for machinery to solidify bars before stamping and packaging. Selecting the right components, like a robust soap plodder or high-torque mixing machine, directly impacts throughput and minimizes downtime. Partnering with experienced suppliers, potentially offering OEM solutions, ensures machinery compatibility and access to technical support. Investing in a reliable laundry soap making line or beauty soap making line, built around core technologies like the vacuum plodder and efficient cutter, is fundamental for scaling production while maintaining stringent quality standards demanded by today’s market.

Optimizing Your Soap Making Production Line for Efficiency and Quality

Optimizing Your Soap Making Production Line for Efficiency and Quality

Posted Date:

By:

If you’re interested in our soap manufacturing equipment or would like to learn more about customized solutions tailored to your specific production needs, please fill out the inquiry form below with details such as your required capacity, soap type, level of automation, etc. As a professional manufacturer of soap machinery, we’re ready to provide you with comprehensive information and a competitive quotation—welcome to contact us!