Investing in a reliable soap making production line is crucial for manufacturers aiming to deliver high-quality bars at scale. Whether you focus on laundry bar soap production lines, toilet soap finishing lines, or specialized beauty soap making lines, the core machinery determines output consistency and operational efficiency.

The process begins with precise ingredient blending. A robust industrial mixer for chemical processing ensures homogeneous mixing of fats, oils, lye, and additives, forming the perfect soap base. This initial stage is foundational; inconsistent mixing leads to poor saponification and subpar bars. The mixed paste then moves to the refining stage, often utilizing a triple roller mill for cosmetics-grade smoothness in premium toilet soaps or beauty bars.

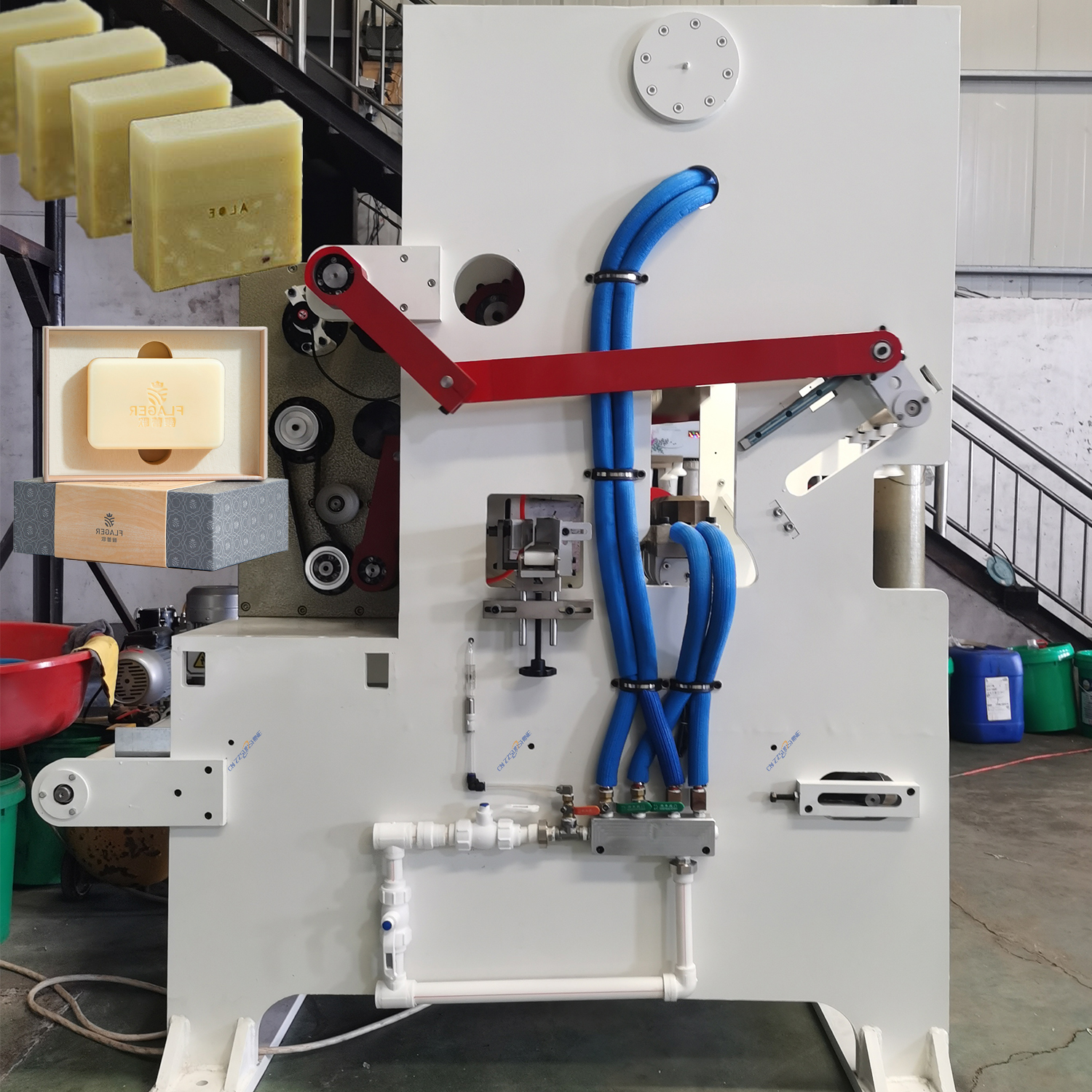

Extrusion is where the soap base transforms into solid bars. A high-quality vacuum plodder is indispensable. This machine compresses the soap noodle under vacuum, removing air pockets to create a dense, uniform log. The density achieved by the vacuum plodder directly impacts the final bar’s hardness, longevity, and lathering properties. For large-scale laundry soap making lines, a heavy-duty soap plodder machine for bar soap ensures continuous, high-volume output.

Following extrusion, precise cutting is essential. An automatic soap cutting machine, or specifically an electric washing soap cutter, provides accurate, consistent bar sizes with clean edges, minimizing waste. For customized shapes or sizes, a custom soap cutting machine can be integrated. Finally, bars proceed to stamping, cooling (often requiring an industrial chiller for machinery to maintain optimal temperatures), and automated packing via an automatic packing machine for food-grade hygiene.

Optimizing your laundry bar soap production line or bath soap making machine setup hinges on integrating compatible, high-performance components: the industrial mixer, vacuum plodder, and automatic soap cutter. Partnering with experienced OEM three roller grinding mill manufacturers and suppliers ensures critical components meet stringent requirements. The goal is a seamless automatic soap production line delivering uniform quality, maximizing throughput, and minimizing downtime for sustained profitability. Careful selection of each machine, focusing on durability and precision, is the key to long-term success in competitive soap manufacturing.