Building a competitive soap manufacturing operation demands efficiency, consistency, and quality control. Implementing a well-integrated **automatic soap production line** is no longer a luxury but a necessity for scale. This guide explores the core components and processes essential for modern **soap making**, whether targeting the **laundry bar soap production line** market or high-end **toilet soap finishing line** requirements.

The journey begins with precise ingredient handling. A robust **industrial mixer for chemical processing** ensures homogeneous blending of fats, oils, alkalis, and additives, forming the initial soap base. This critical stage sets the foundation for quality. The mixed mass then undergoes refining. Here, a **three roller mill for cosmetics** or similar refining equipment (like an **OEM three roller grinding mill**) micronizes the paste, creating a smooth texture crucial for premium **beauty soap making line** output or standard bars.

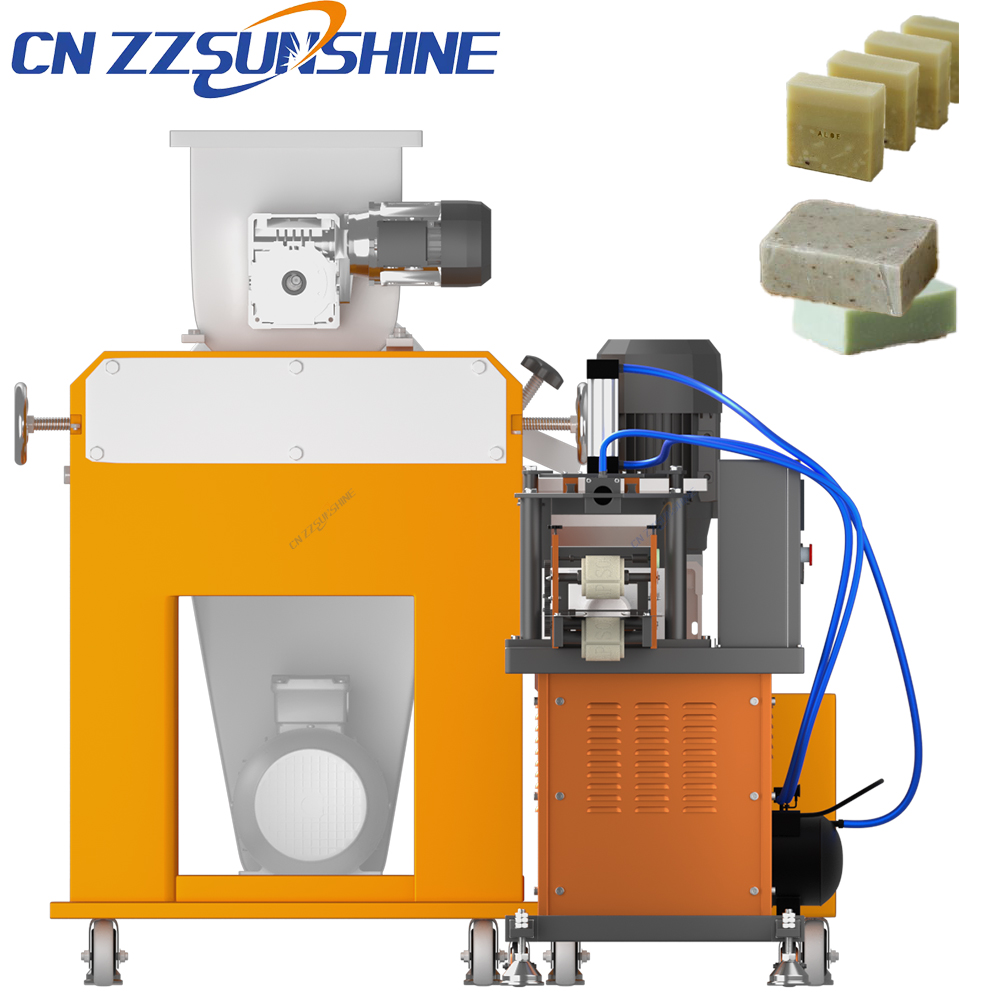

Refined soap enters the extrusion phase, the heart of shaping. A high-performance **soap plodder machine**, particularly a **vacuum plodder**, is vital. This equipment compacts the soap under vacuum, removing trapped air that causes bubbles and imperfections, resulting in dense, long-lasting bars. The extruded continuous log then moves to cutting. Precision is paramount. An **automatic block cutter machine** or **custom soap cutting machine** slices the log into uniform billets with minimal waste. For specific applications like **laundry soap making line**, an **electric washing soap cutter** provides the necessary accuracy and speed.

Following cutting, the billets progress to stamping, embossing, cooling, and packaging. While not always integrated into the core extrusion line, these finishing stages are integral to the complete **automatic soap production line**. Efficient **bath soap making machine** operations often integrate cooling tunnels before automated wrapping and cartoning.

Choosing the right machinery supplier is critical. Look for partners offering reliable **soap plodder**, **soap mixer**, and **mixing machine** solutions, backed by engineering support. Whether you need a compact **laundry soap making line** or a comprehensive **toilet soap finishing line** for premium products, a properly designed and integrated **automatic soap production line** delivers the throughput, consistency, and product quality demanded by today’s market, maximizing your return on investment.