Demanding markets require robust, efficient laundry bar soap production lines. Achieving consistent quality and high output hinges on selecting the right integrated machinery and optimizing each stage of the process. Here’s a breakdown of the core components and strategies for a superior line.

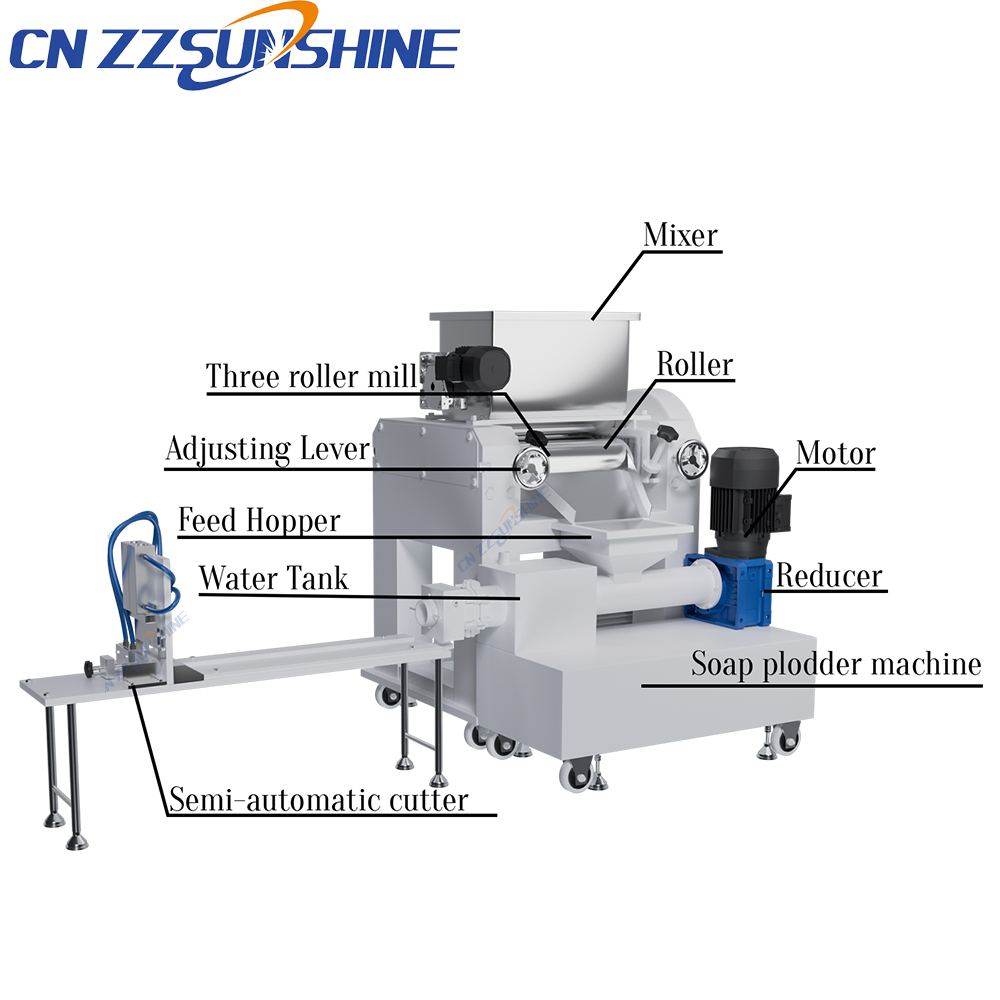

The foundation lies in thorough mixing. A heavy-duty industrial mixer for chemical processing is essential. It must handle the precise blending of fats, oils, alkalis, and additives to create a homogenous soap base. Inconsistent mixing here leads to downstream defects in texture, lather, and cleaning power. Moving the mixed mass efficiently to the next stage is critical.

The heart of bar soap density and texture is the extrusion phase. Modern lines leverage a high-performance vacuum plodder machine. This equipment compresses the soap under vacuum, meticulously removing trapped air. The result? A denser, harder, longer-lasting bar with superior lather and reduced waste. Twin plodders (refiner and final vacuum plodder) are often employed for maximum deaeration and smooth extrusion. The vacuum plodder stage is non-negotiable for premium laundry bars.

Following extrusion, precision cutting is paramount. An automatic soap cutting machine, often an electric washing soap cutter, delivers uniform bar weights and dimensions at high speeds. For manufacturers needing unique bar shapes or sizes, investing in a custom soap cutting machine provides vital flexibility. Accuracy here minimizes giveaway and ensures packaging consistency.

Integrating these components – the industrial mixer, the vacuum plodder, and the automatic cutter – into a seamless automatic soap production line is key. Automation minimizes manual handling, boosts throughput, and enhances worker safety. Look for machinery designed for easy cleaning and maintenance to reduce downtime. Partnering with experienced manufacturers offering OEM solutions ensures the line is tailored to your specific base recipe, throughput goals, and bar specifications.

Optimizing your laundry bar soap production line isn’t just about individual machines like the soap plodder or mixer; it’s about the synergistic performance of the entire system. Focus on high-capacity, reliable equipment, particularly the vacuum plodder for density and the automatic cutter for precision, to achieve a competitive edge through consistent quality, reduced waste, and maximized output. The return on investment comes from lower operational costs and a superior product commanding market preference.