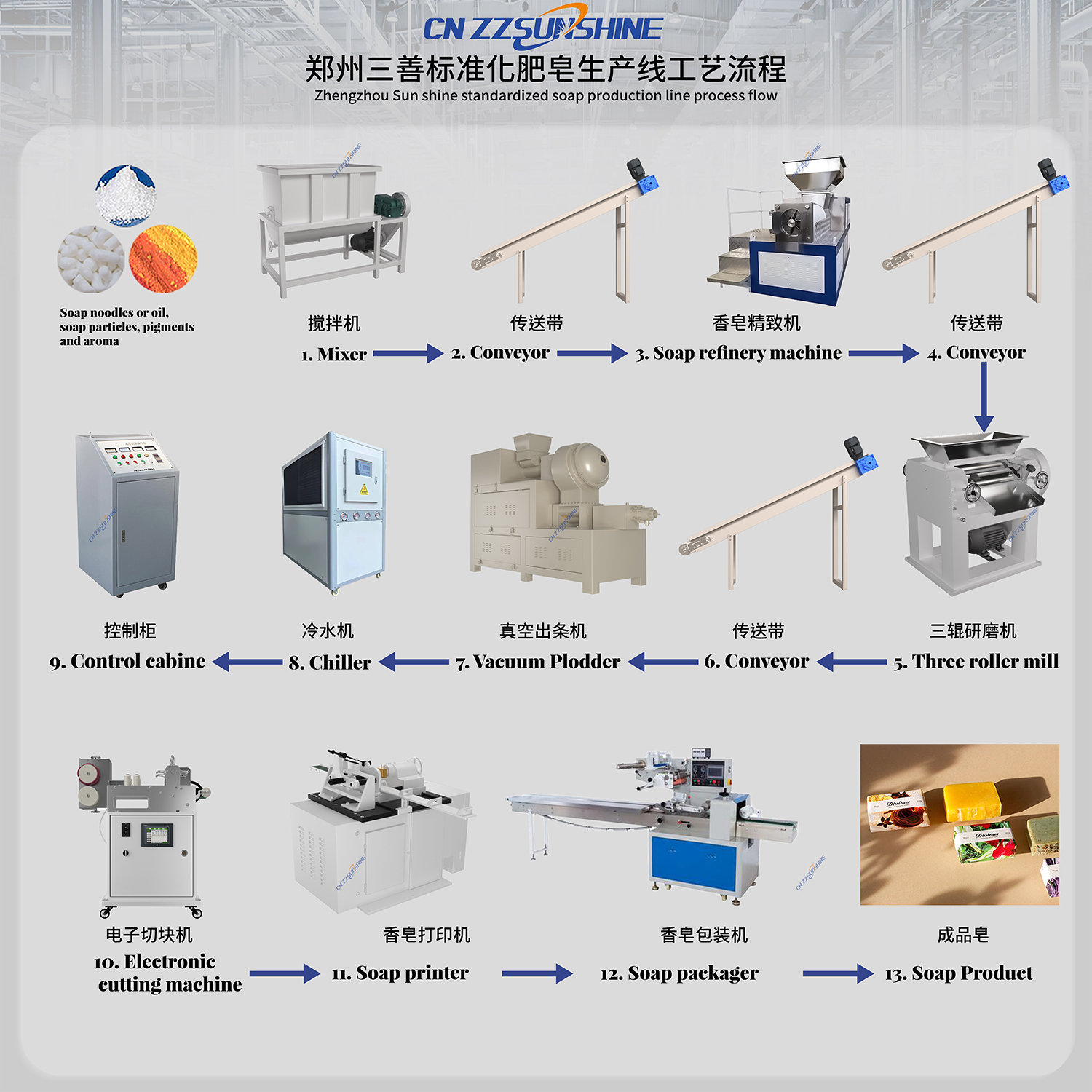

Streamlining the manufacturing of high-volume laundry bar soap demands an integrated, efficient production line. At its core, a robust **soap making production line** combines several critical pieces of **soap making machine**ry working in unison. The process begins with the **soap mixer** or **mixing machine**, where raw fats, oils, and caustic soda are blended into a homogeneous soap base. Consistent mixing is paramount for quality.

This base then undergoes refining, often utilizing a **three roller mill for cosmetics**-grade smoothness, essential even for laundry bars where skin feel matters during use. The refined soap noodles move to the heart of the line: the **soap plodder machine for bar soap**. Here, a **vacuum plodder** performs the crucial dual function of compressing the soap mass under vacuum to remove air pockets and extruding a continuous, dense log. This step is vital for producing bars that are hard, long-lasting, and won’t crumble. Opting for a high-quality **soap plodder** directly impacts bar density and reduces waste.

The continuous soap log proceeds to the cutting stage. An **automatic block cutter machine** first sections the log into manageable blocks. Precision is then handled by the **electric washing soap cutter** or a **custom soap cutting machine**, which slices the blocks into individual bar-sized units. Automation here ensures uniform size and weight, critical for packaging and consumer satisfaction. This **cutter** technology minimizes manual handling and boosts throughput.

Finally, the cut bars enter the finishing stage – stamping, embossing, and cooling – before automated packing. Investing in a well-designed **laundry bar soap production line**, incorporating a **vacuum plodder** and precision **electric washing soap cutter**, delivers significant advantages. Factories achieve higher output with consistent quality, reduced labor costs, and minimized material loss. Whether upgrading an existing setup or implementing a new **automatic soap production line**, focusing on the synergy between the **soap plodder**, refining mills, and cutting systems unlocks true manufacturing efficiency and profitability.