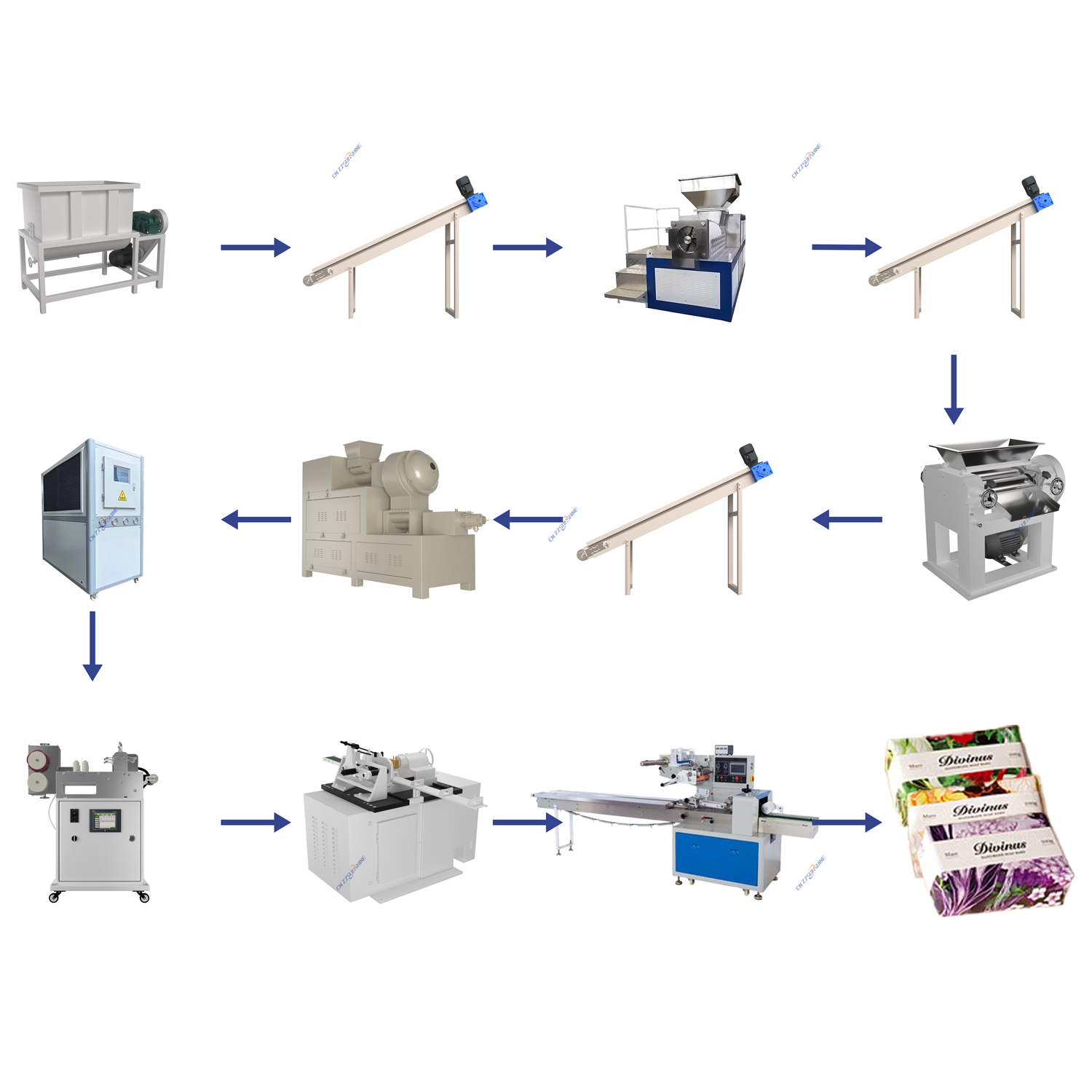

Building a competitive industrial soap production line demands precision machinery at every stage. Understanding the core equipment – the soap plodder machine for bar soap, industrial mixers for chemical processing, and specialized cutters – is crucial for efficiency and product quality. The process fundamentally starts with homogenization. A robust industrial mixer ensures consistent blending of fats, oils, lye, and additives, creating a uniform soap base essential for reliable final bars.

This mixed mass then enters the refining phase, often utilizing a vacuum plodder. This critical piece of equipment kneads and compresses the soap under vacuum conditions. Removing air pockets is vital; it prevents cracking, ensures density, and significantly enhances the bar’s longevity and lathering properties. The vacuum plodder machine for bar soap delivers the smooth, dense extruded noodle required for the final forming stage.

Next comes forming and cutting. Depending on the desired bar type – laundry soap or premium toilet soap – the line may incorporate different forming logs. Precision cutting is non-negotiable. An automatic soap cutting machine, or specifically an electric washing soap cutter, provides the accuracy and speed needed for consistent bar weights and clean edges, minimizing waste. For high-volume operations, integrating an automatic soap production line streamlines the entire sequence from mixing through cutting, maximizing throughput.

Beyond the core plodder, mixer, and cutter, auxiliary systems play supporting roles. An efficient industrial chiller for machinery is often indispensable to control temperatures during mixing and plodding, especially in warmer climates or for sensitive formulations. Partnering with experienced OEM suppliers ensures access to reliable equipment like custom soap cutting machines designed for specific bar dimensions or textured finishes. Whether establishing a dedicated laundry bar soap production line, a toilet soap finishing line, or a versatile bath soap making machine setup, selecting high-performance machinery like a robust vacuum plodder and precise automatic cutter directly impacts output quality, operational costs, and profitability. Investing in the right technology foundation is key.