In today’s competitive market, producing high-quality bar soap demands more than just good formulations; it requires precision-engineered industrial soap making machinery. The right equipment streamlines your entire laundry bar soap production line or toilet soap finishing line, impacting everything from texture and consistency to output and profitability. Understanding the core components is crucial for operators and procurement managers alike.

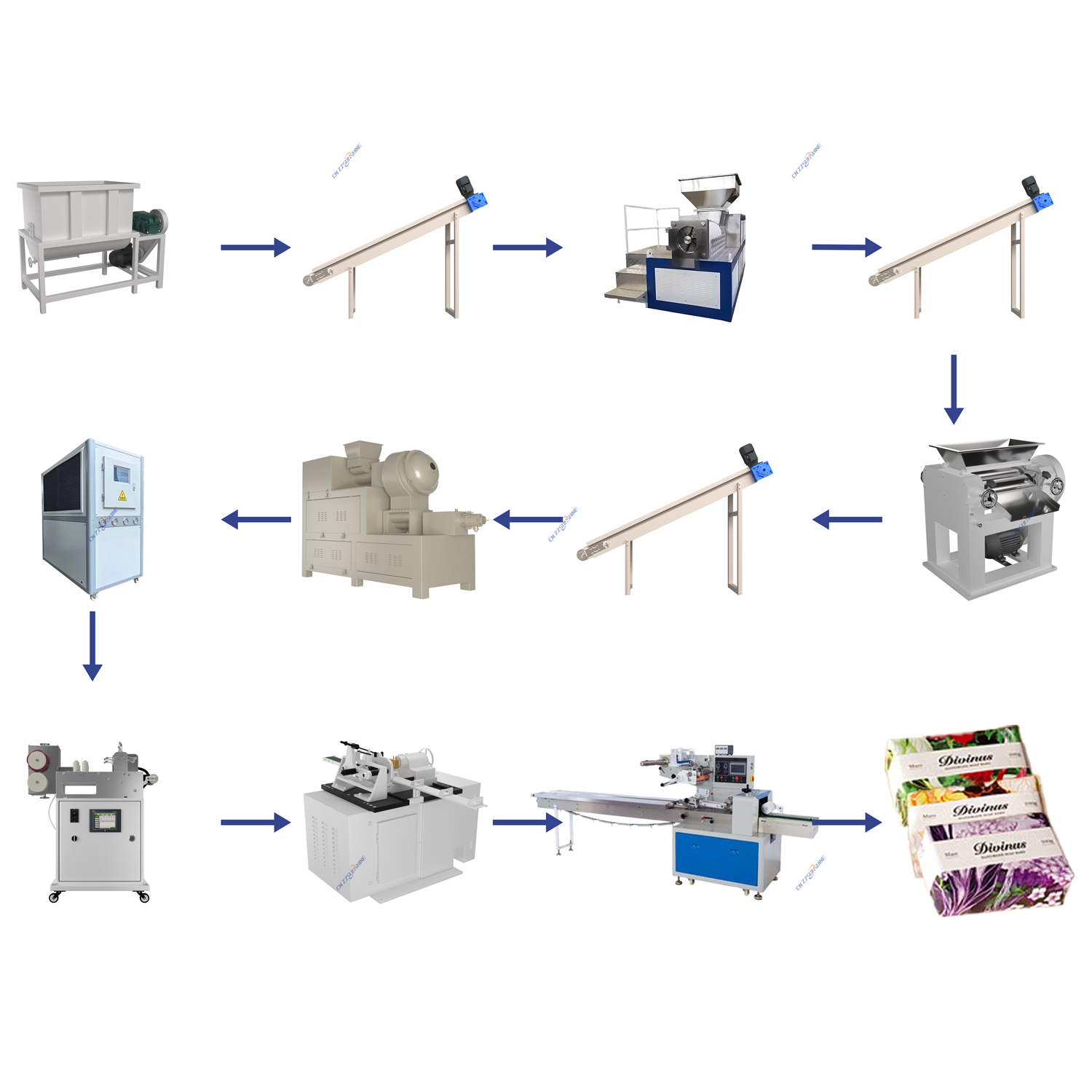

The process typically begins with robust mixing. An industrial mixer for chemical processing ensures homogeneous blending of oils, fats, lye, and additives under controlled conditions, forming the crucial soap base. This stage sets the foundation for the final bar’s properties. From the mixer, the soap base moves to refining and extrusion. Here, the soap plodder machine for bar soap takes center stage. Modern vacuum plodder units are particularly effective, removing air pockets under vacuum to create a dense, consistent grain. This step is vital for producing bars that are firm, long-lasting, and have a smooth finish, whether for laundry or bath applications.

Following extrusion, the continuous soap log requires precise cutting. An electric washing soap cutter offers clean, programmable cuts, minimizing waste and ensuring uniform bar weights crucial for packaging and consumer satisfaction. For high-volume facilities, integrating an automatic soap production line, incorporating automated feeding, extrusion, cutting, and stamping, significantly boosts throughput while reducing labor costs and human error. When selecting machinery, consider partnering with experienced manufacturers offering reliable OEM three roller grinding mill options for specialized refining needs or custom soap cutting machine solutions for unique bar shapes or sizes.

Investing in high-performance industrial soap making machinery, including advanced soap plodder and mixer units, is not merely an expense; it’s a strategic decision. Optimized bath soap making machine lines or laundry soap making line configurations directly translate to superior product quality, consistent output, reduced waste, and enhanced competitiveness. Whether upgrading an existing toilet soap finishing line or establishing a new beauty soap making line, prioritizing efficient, reliable machinery is fundamental to success in the industrial soap sector.