Implementing a robust industrial soap making line demands precision engineering at every stage. For manufacturers targeting consistent quality and high throughput, understanding the integration of specialized equipment is paramount. The process typically commences with a high-capacity industrial mixer for chemical processing, ensuring homogeneous blending of fats, alkalis, and additives. This critical phase directly impacts soap bar texture and performance characteristics.

Transitioning from the mixer, the blended soap base moves to refining. While three-roller mills are common in cosmetics, a dedicated soap plodder machine for bar soap is essential here. Modern vacuum plodder units are particularly effective, removing air pockets under vacuum to create a dense, uniform grain structure – crucial for preventing cracking and ensuring bar longevity in both laundry soap making lines and toilet soap finishing lines.

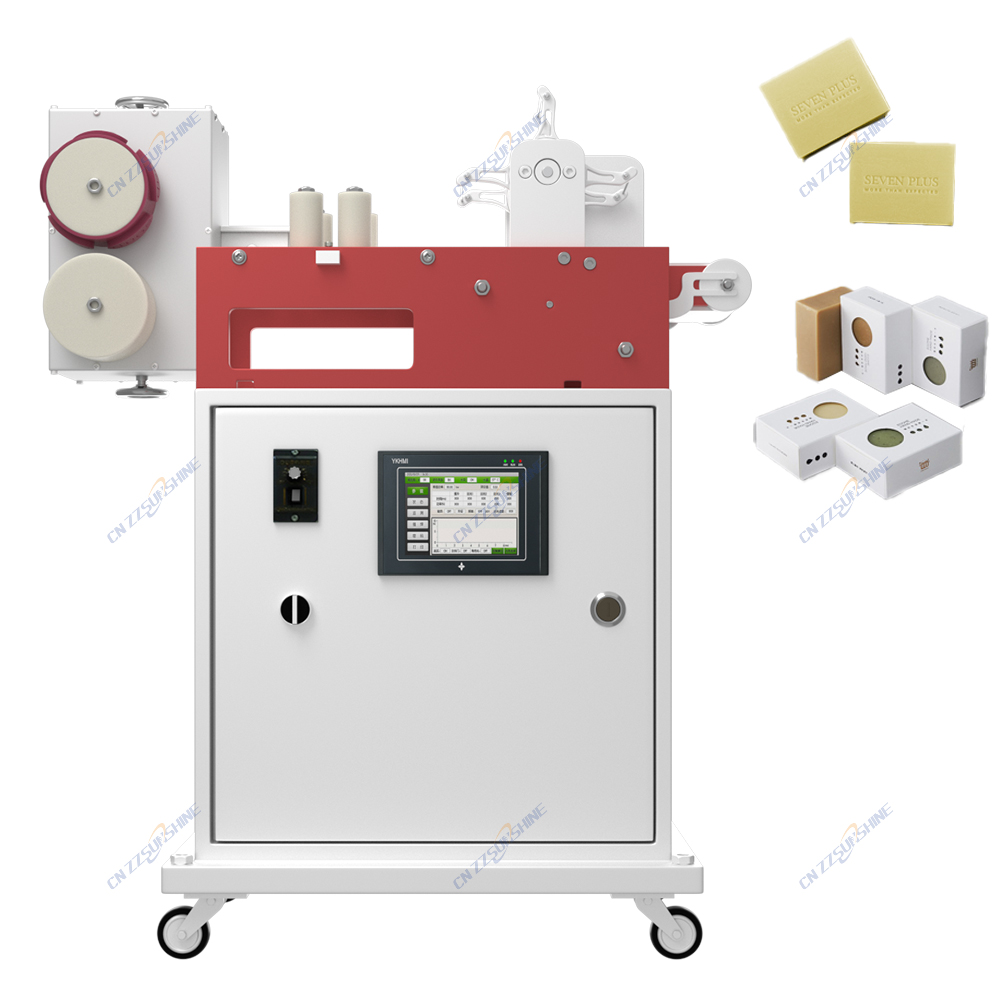

The extruded soap log then proceeds to cutting. Efficiency peaks with an automatic block cutter machine, often followed by specialized electric washing soap cutters or custom soap cutting machines for precise sizing and stamping. This automation minimizes waste and ensures dimensional accuracy for downstream packaging. Integrating an automatic packing machine for food-grade standards is vital for hygiene and presentation, especially in bath soap making machines and beauty soap making lines.

For large-scale operations like laundry bar soap production lines, optimizing the entire automatic soap production line is key. This includes selecting equipment with high uptime, easy maintenance, and energy efficiency. Partnering with experienced suppliers, potentially leveraging OEM expertise for critical components like the three roller grinding mill or sourcing a factory price industrial chiller for machinery cooling requirements, can significantly impact operational costs and product consistency. The right soap making machine selection and integration directly translates to superior product quality, reduced labor dependency, and enhanced profitability in competitive markets.