For manufacturers aiming to scale soap production, investing in a streamlined industrial soap making line is no longer optional; it’s critical for competitiveness. Moving beyond rudimentary manual methods requires integrating specialized, automated machinery designed for precision and high-volume output. The core of any efficient laundry bar soap production line or toilet soap finishing line begins with robust mixing. An industrial mixer for chemical processing ensures homogeneous blending of fats, oils, lye, and additives under controlled conditions, forming the essential soap base crucial for consistent quality.

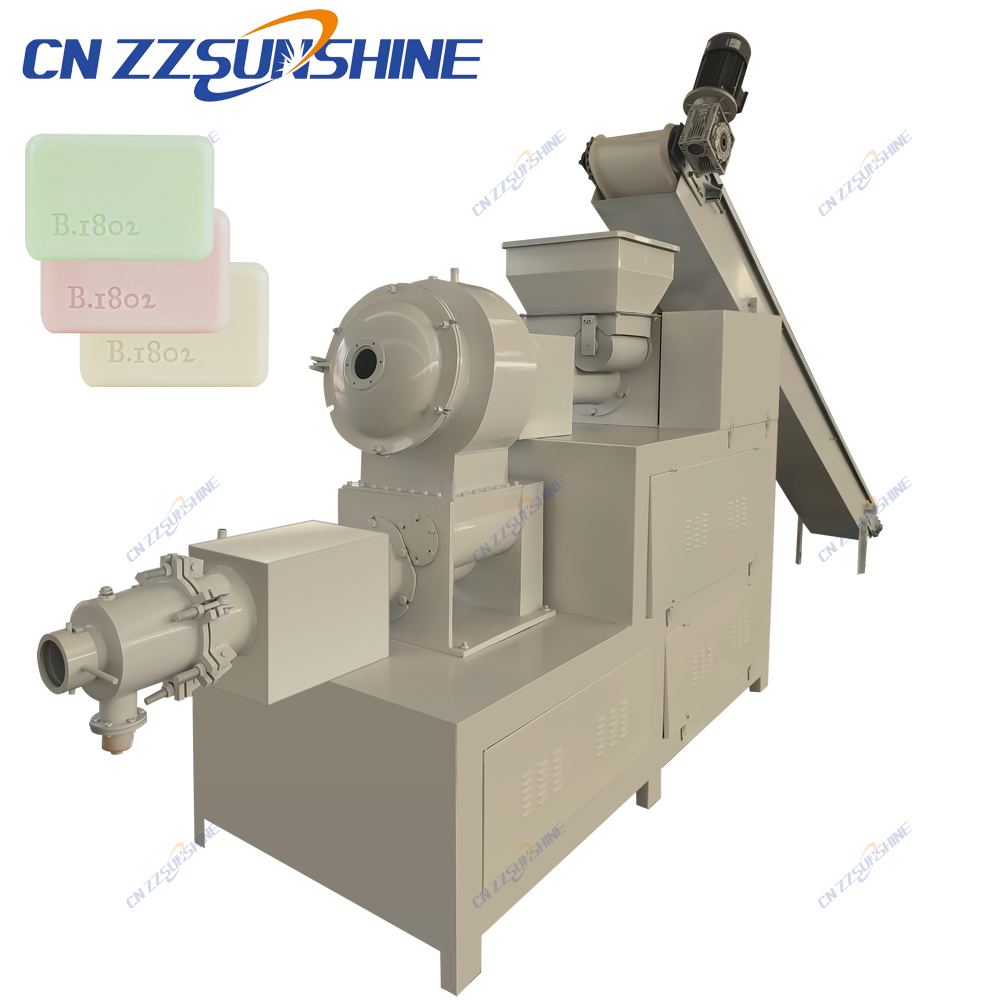

This base then undergoes refinement, often utilizing a three roller mill for cosmetics-grade quality, especially vital for beauty soap making lines where smooth texture is paramount. The refined soap next enters the extrusion phase. Here, a modern vacuum plodder machine for bar soap becomes indispensable. By removing air pockets under vacuum, the plodder produces a dense, uniform soap noodle ready for final forming. This step significantly enhances bar durability and lathering properties compared to non-vacuum methods.

The final shaping stage relies heavily on precision cutting. An automatic soap production line incorporates either a custom soap cutting machine or an electric washing soap cutter. These devices slice the extruded soap log into perfectly sized, uniform bars with minimal waste at high speeds. For complete integration, pairing the line with an automatic packing machine for food-grade products ensures hygienic, efficient packaging ready for distribution. Choosing the right combination of soap plodder, soap mixer, and cutter, potentially from a reputable China supplier offering OEM options, directly impacts throughput, consistency, and ultimately, profitability. The transition to a fully integrated automatic soap production line delivers tangible ROI through reduced labor costs, minimized waste, superior product uniformity, and the ability to reliably meet large-scale market demands.