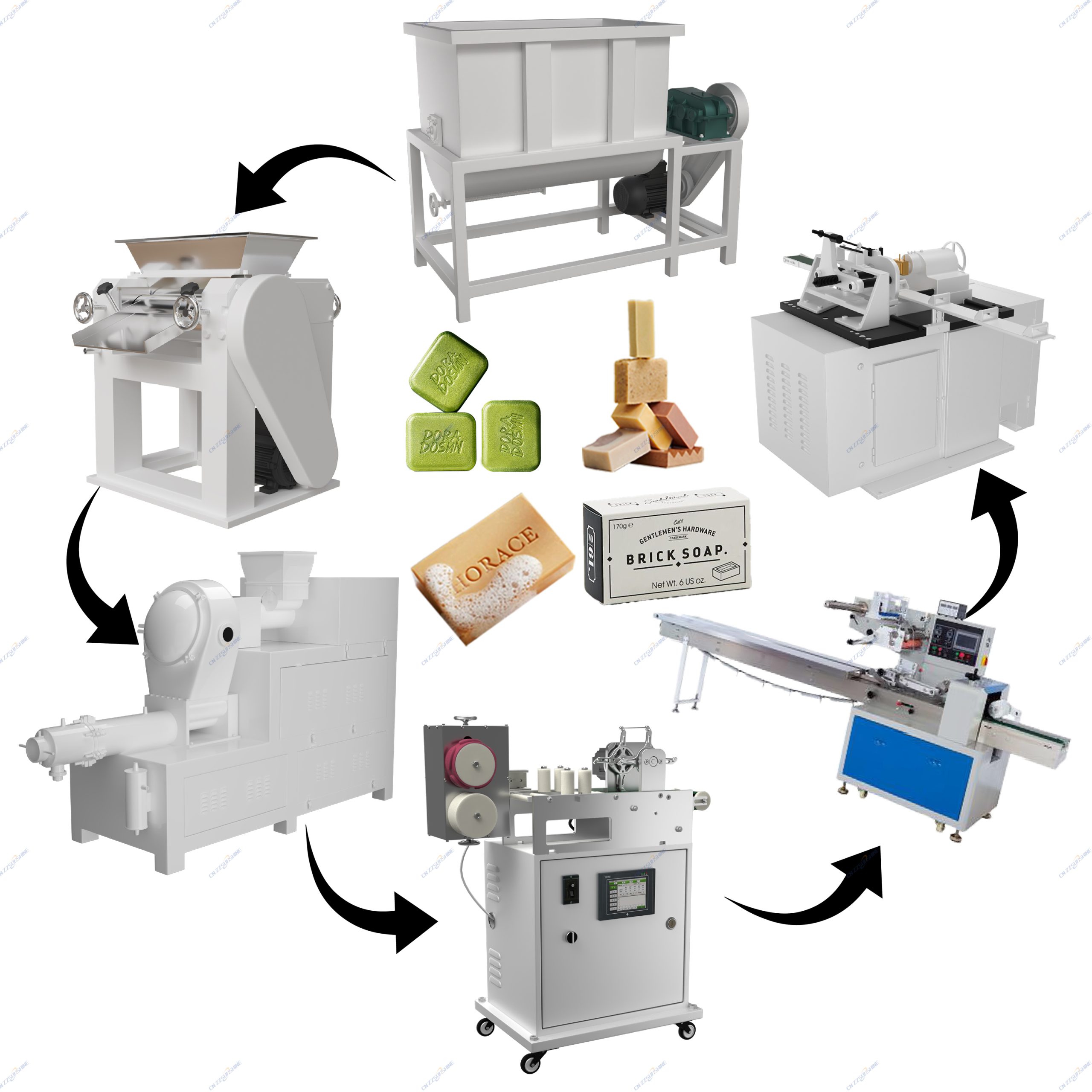

Streamlining soap manufacturing demands precision equipment at every stage. For producers targeting consistent quality in laundry bar soap production lines or intricate beauty soap making lines, investing in the right integrated systems is paramount. The process truly begins with a robust industrial mixer for chemical processing. This stage is critical; thorough blending of fats, oils, lye, and additives ensures uniform saponification and desired properties in the final bar, whether for heavy-duty laundry or delicate toilet applications.

Following mixing, the homogeneous soap mass moves to refining and forming. Here, the vacuum plodder machine for bar soap becomes the heart of the operation, especially in modern automatic soap production lines. High-quality vacuum plodders remove air pockets, significantly enhancing bar density and longevity. This step is vital for both laundry soap making lines and premium toilet soap finishing lines. The vacuum plodder extrudes a continuous, compacted log, ready for precision cutting.

The final shaping stage is where accuracy defines the product. Utilizing a custom soap cutting machine allows producers to achieve exact dimensions tailored to specific markets or branding needs. For high-volume operations, an electric washing soap cutter offers speed and clean cuts, minimizing waste. Advanced automatic block cutter machines further enhance efficiency, especially in large-scale bath soap making machine setups. The choice of cutter – from simple mechanical units to sophisticated electric washing models – directly impacts appearance, weight consistency, and packaging efficiency.

Integrating these core components – a reliable industrial mixer, an efficient vacuum plodder, and a precise cutting solution – forms the backbone of a high-performance automatic soap production line. Whether establishing a new laundry bar soap production line or upgrading an existing toilet soap finishing line, focusing on the synergy between the soap mixer, plodder machine, and cutter ensures optimal throughput, reduced waste, and superior bar quality. The return on investment manifests in consistent output, lower operational costs per unit, and the ability to meet diverse market demands efficiently.