The demand for consistent, high-quality bar soaps requires advanced manufacturing solutions. Implementing a fully integrated automatic soap production line significantly enhances efficiency, product uniformity, and cost-effectiveness for manufacturers targeting both the laundry soap and toilet soap markets. This integrated approach streamlines the entire process from raw material handling to finished bars.

A robust soap making production line starts with precise ingredient handling. Industrial mixers for chemical processing ensure homogeneous blending of fats, oils, lye, and additives under controlled conditions. This foundational step is critical for achieving the desired saponification and final product properties. The mixed soap base then undergoes refining, often utilizing a three roller mill for cosmetics-grade smoothness, essential for premium toilet soap finishing lines.

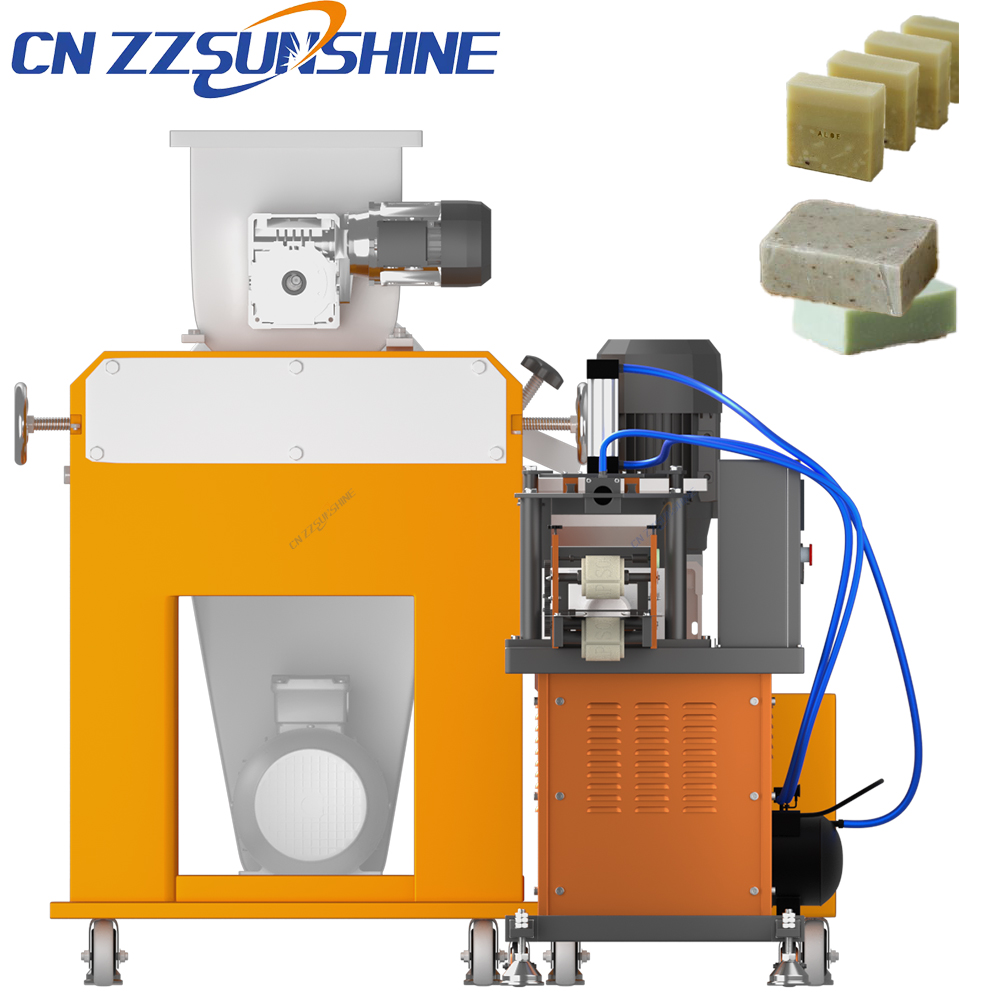

The core extrusion phase relies on specialized equipment like the vacuum plodder machine. This component compacts the soap mixture, removes air pockets for denser bars, and shapes the continuous soap log. Modern vacuum plodders offer exceptional control over density and texture. Following extrusion, the continuous log proceeds to cutting. Here, an automatic soap cutter machine, often an electric washing soap cutter, ensures precise, consistent bar sizes with clean edges – vital for both laundry bar soap production lines and bath soap making machines. Automation minimizes waste and maximizes throughput.

Finally, the cut bars move through stamping, cooling tunnels (often supported by factory price industrial chillers), and packaging. Integrating an automatic packing machine for food-grade standards ensures the finished product is protected and shelf-ready. This entire sequence – from the initial soap mixer stage through extrusion via the soap plodder, cutting, and packing – constitutes the modern beauty soap making line or laundry soap making line.

Key advantages of adopting a complete automatic soap production line include reduced labor dependency, minimized human error, enhanced hygiene control, consistent bar weight and appearance, and higher overall output. Whether establishing a new laundry soap making line or upgrading an existing toilet soap finishing line, investing in integrated automation with reliable components like the vacuum plodder and automatic cutter delivers a compelling return on investment through superior product quality and optimized operational efficiency.